Six Sigma In 9 Minutes | What Is Six Sigma? | Six Sigma Explained | Six Sigma Training | Simplilearn

Summary

TLDRThis script introduces Six Sigma, a set of tools and techniques aimed at improving manufacturing processes and reducing defects. It explains the DMAIC and DMADV methodologies, which help organizations enhance existing products and create new ones, respectively. The script also touches on Lean principles and the combined approach of Lean Six Sigma, which focuses on eliminating waste and inefficiencies to better satisfy customer needs. The video is from the Simply Learn channel, which educates viewers on these methodologies and their applications across various industries.

Takeaways

- 🚗 The company faces a decline in luxury car production and a drop in windshield wiper quality.

- 🛠️ Six Sigma is a methodology introduced by Bill Smith in 1980 at Motorola to improve process efficiency and reduce defects.

- 🎯 Six Sigma aims for near-perfect quality, allowing only 3.4 defects per million opportunities.

- 🔍 DMAIC (Define, Measure, Analyze, Improve, Control) is a Six Sigma methodology used for improving existing processes.

- 📊 In DMAIC, the 'Define' stage identifies issues and customer requirements, focusing on the manufacturing process.

- 📈 The 'Measure' phase quantifies the current process performance, such as daily car production and assembly time.

- 🔍 The 'Analyze' phase investigates causes of defects or variations, like machine performance issues.

- 🛠️ The 'Improve' stage implements changes to address defects, such as replacing faulty machines or streamlining processes.

- 🔒 The 'Control' phase ensures ongoing process stability and performance through regular adjustments.

- 🏎️ DMADV (Define, Measure, Analyze, Design, Verify) is used for creating new products or services from scratch, also known as DFSS (Design for Six Sigma).

- 🏗️ Lean is a methodology that focuses on removing waste and non-value-adding steps in a process, originating from the Japanese manufacturing industry.

- 🤝 Lean Six Sigma combines the principles of Lean and Six Sigma to eliminate problems and waste while improving customer satisfaction.

Q & A

What is the main issue faced by the luxury car company in the script?

-The luxury car company is facing a decrease in production numbers and a decline in the quality of the windshield wipers installed on their cars.

What is Six Sigma and how does it help in improving manufacturing processes?

-Six Sigma is a set of tools and techniques aimed at reducing defects and variability in processes within an organization. It helps in identifying and eliminating delays, improving processes, and ensuring high-quality output with minimal errors.

Who introduced the Six Sigma concept and when was it introduced?

-The Six Sigma concept was introduced by Bill Smith in 1980 while he was working for Motorola.

What is the DMAIC methodology and what does it stand for?

-DMAIC is a Six Sigma methodology that stands for Define, Measure, Analyze, Improve, and Control. It is used for improving existing processes by identifying issues, measuring current performance, analyzing causes of defects, making improvements, and controlling the new process.

What are the main steps involved in the Define phase of DMAIC?

-In the Define phase, the issues faced are identified, opportunities for improvement are determined, and customer requirements are assessed.

What metrics are measured during the Measure phase of DMAIC?

-During the Measure phase, metrics such as the number of cars produced daily, time taken to assemble a car, number of windshield wipers attached daily, time taken for attachment, and defects detected from each machine are measured.

What is the purpose of the Analyze phase in DMAIC?

-The Analyze phase is used to determine the root causes of defects or variations by analyzing previous data and identifying areas for improvement.

What changes were made in the Improve phase of the script's example?

-In the Improve phase, the company replaced faulty machines and modified the manufacturing process to attach wheels to the car frame in the initial stages, allowing for faster movement of the car across the assembly area.

What is the DMADV methodology and what does it stand for?

-DMADV is another Six Sigma methodology that stands for Define, Measure, Analyze, Design, and Verify. It is used for creating new products or services from scratch, focusing on customer requirements and optimizing the design process.

How does Lean Six Sigma combine the principles of Lean and Six Sigma?

-Lean Six Sigma combines the principles of Lean, which focuses on eliminating waste and increasing efficiency, with Six Sigma's focus on reducing defects and improving quality, to provide a comprehensive approach to process improvement.

What is the purpose of the Lean methodology in manufacturing?

-The purpose of the Lean methodology is to remove any part of the process that does not add value to the customer, aiming to do more with less while improving the quality of the output.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is Six Sigma?

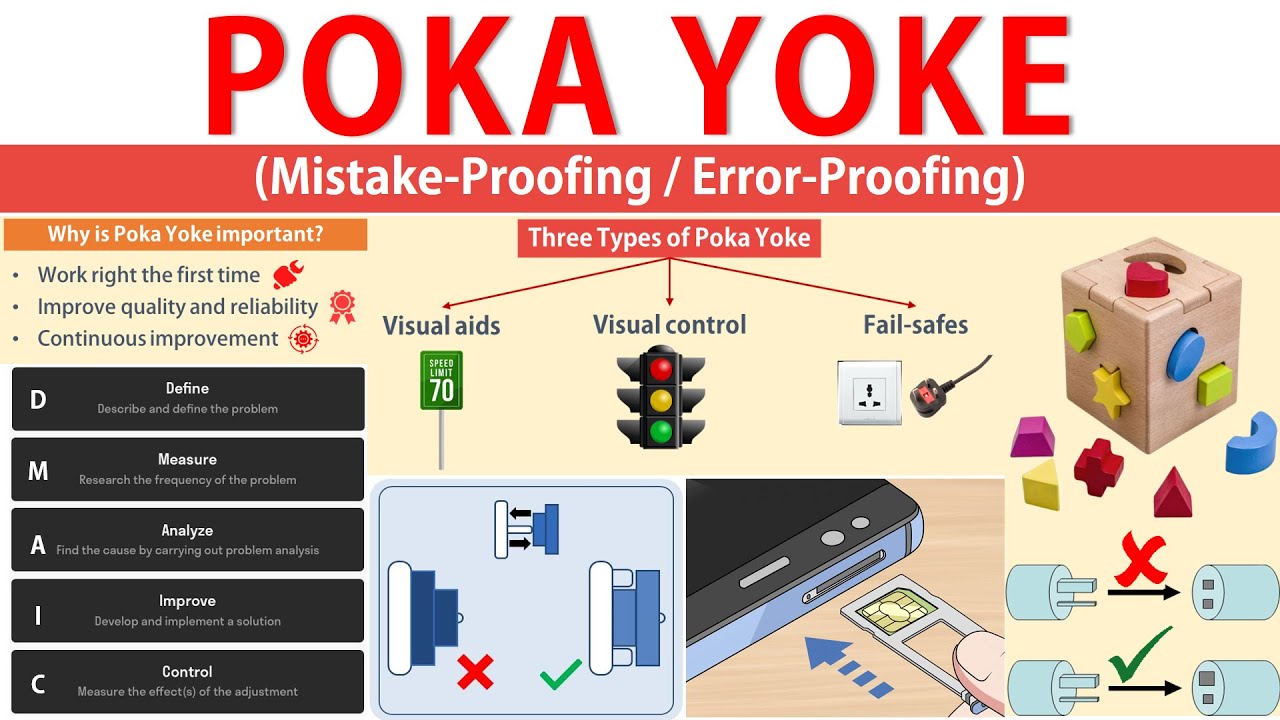

Poka Yoke (Error Proofing) - Meaning, Concept, Types, Stages, & Implementation Explained.

Six Sigma Complete Project Example HD

#7 Karir dan Profesi : Perancangan Proses Produksi (S1 T.Industri, Kelas 1) - SEG 2

Ejemplo Lean Six Sigma - Sumario Ejecutivo - Proceso Logístico: Inventarios | VARIEXA

7 Quality Control Tools in Tamil| 7 QC Tools| Six Sigma| 7 Basic Quality Control Tools|

5.0 / 5 (0 votes)