Bio-processing overview (Upstream and downstream process)

Summary

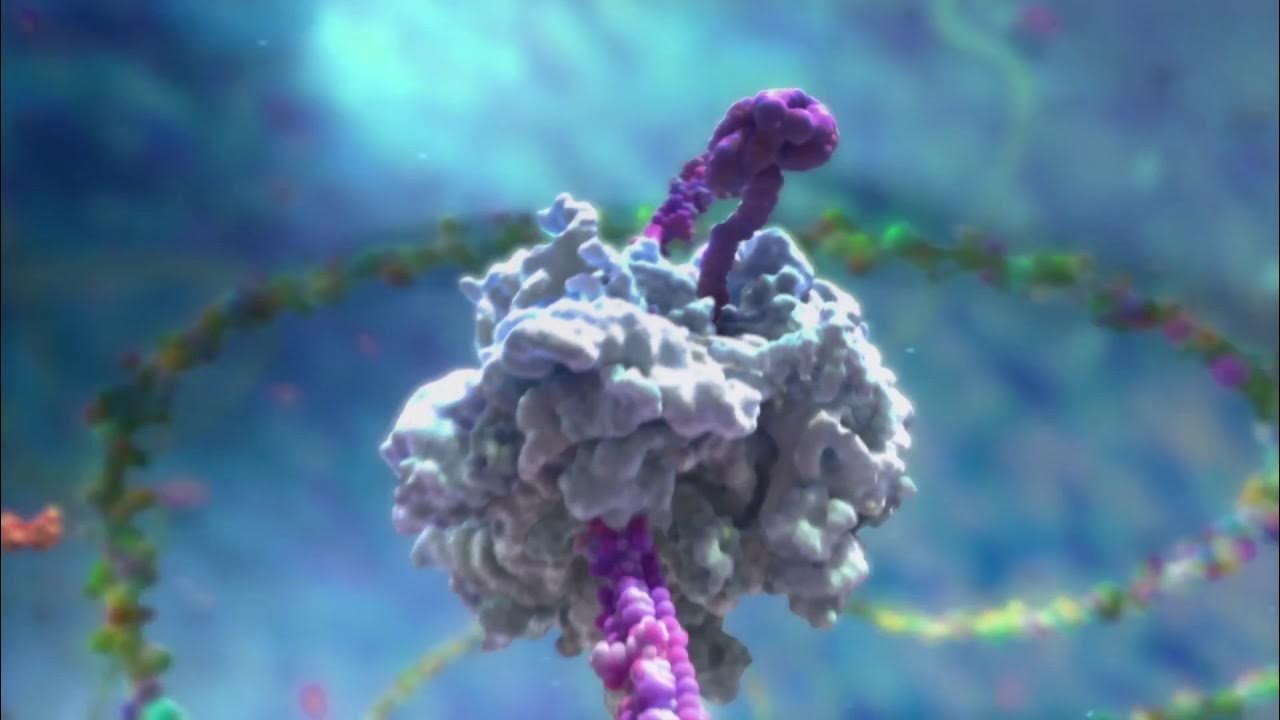

TLDRThis video offers an insightful overview of bioprocessing, a technique that harnesses biological resources like living cells to produce biomedically relevant products such as enzymes and recombinant proteins. It explains the process taking place in bioreactors, involving various cell types, and differentiates between upstream and downstream processing. Upstream focuses on cell growth and product generation, while downstream encompasses recovery, purification, and quality control of the synthesized products. The video also touches on industrial-scale challenges and the equipment used, such as centrifuges and chromatography systems, highlighting the transition from lab-scale to bulk production in the bioprocessing industry.

Takeaways

- 🧪 Bioprocessing is a technique that utilizes biological resources such as living cells to produce enzymes, metabolites, and other products with biomedical relevance.

- 🌱 The process takes place in a bioreactor, which provides a controlled environment for the biological cells to function, and can involve bacteria, mammalian cells, or plant cells.

- 🛠️ Bioprocessing is an industrial-scale process, differentiated from lab-scale by the scale of the reaction, not the type of reaction.

- 🔬 Products generated through bioprocessing can include secreted metabolites, enzymes for research or therapeutic drugs, and recombinant proteins for biomedical research.

- 🏭 The industrial production of biological products involves scaling up from a small culture volume to a large bioreactor, where the product is generated in bulk.

- 🌱 The bioprocessing industry starts with a seed stock of bacteria, which is then transfected with a plasmid and scaled up to produce the desired product.

- 🔄 The process involves both upstream and downstream processing; upstream refers to cell growth and product generation, while downstream involves recovery, purification, and packaging of the product.

- 🌡️ Bioreactors are equipped with various components including a sterile tank, stirring mechanism, temperature control, and aeration to ensure optimal conditions for cell growth.

- 🔬 Centrifuges and filtration units are used in the downstream process to separate cells from the product and to purify the product based on its location (intracellular or extracellular).

- 🔄 Cell disruption systems are used for intracellular products to release the product from within the cells, followed by purification steps such as chromatography.

- 🏷️ Quality control is a critical step in bioprocessing to ensure the functionality and safety of the product before it is released for use.

Q & A

What is bioprocessing?

-Bioprocessing is a technique that utilizes biological resources, such as living cells, to produce products like enzymes and metabolites with biomedical relevance in a controlled bioreactor environment.

What are the types of biological cells that can be used in bioprocessing?

-The biological cells used in bioprocessing can be bacteria, mammalian cells, or plant cells.

What are some examples of products generated using bioprocessing?

-Examples of products generated using bioprocessing include secreted metabolites, enzymes for biomedical research, therapeutic drugs, and recombinant proteins.

What is the purpose of a bioreactor in bioprocessing?

-A bioreactor is used to carry out the bioprocess in a controlled environment, allowing for the growth of biological cells and the production of the desired products.

How does the scale of bioprocessing differ from a small-scale lab experiment to an industrial process?

-In a lab, a small vessel is used for a small scale work, whereas in an industrial process, a much larger bioreactor is used to produce the product in bulk, catering to a larger demand.

What is the role of a seed stock in bioprocessing?

-A seed stock contains bacteria that are transfected with the desired plasmid. It serves as the starting point for gradually scaling up the culture volume in bioprocessing.

What are the components of a bioreactor?

-A bioreactor consists of a sterile tank for the broth, a stirring paddle attached to a motor, a coolant system to maintain temperature, an aeration unit for oxygen supply, and electronic control systems.

What is the difference between upstream and downstream processing in bioprocessing?

-Upstream processing involves the generation of cells in large amounts and the production of the product, while downstream processing includes the recovery, purification, polishing, quality control, and packaging of the product.

How is an extracellular product purified and recovered in bioprocessing?

-An extracellular product is purified and recovered by connecting the bioreactor tank to a centrifuge and then to a filtration unit, which separates the cells from the metabolites and purifies the product of interest using column chromatographic techniques.

How is an intracellular product such as an enzyme recovered in bioprocessing?

-An intracellular product is recovered by first disrupting the cells using a cell disruption system, which mechanically shears the cells to release the product. The product is then separated from the debris using centrifugation and further purified through downstream processing steps.

What is the importance of quality control in bioprocessing?

-Quality control is crucial in bioprocessing to ensure that the final product is functional, meets the required specifications, and is safe for release into the market.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тариф5.0 / 5 (0 votes)