Pitch sobre Discordâncias

Summary

TLDRThis video discusses dislocations in metallurgy, explaining their significance in crystal structures and material properties. It covers the types of dislocations (edge, screw, and mixed), how dislocations affect the mechanical strength and deformation of metals, and the role of the Burgers vector. The video also highlights mechanisms that impede dislocation movement, such as precipitates, and introduces Frank-Read sources that cause dislocations to multiply under stress. Understanding these concepts is crucial for improving the mechanical properties of metals and their resistance to deformation.

Takeaways

- 😀 Dislocations are linear defects in crystalline structures that cause atomic misalignment, resulting in distortions.

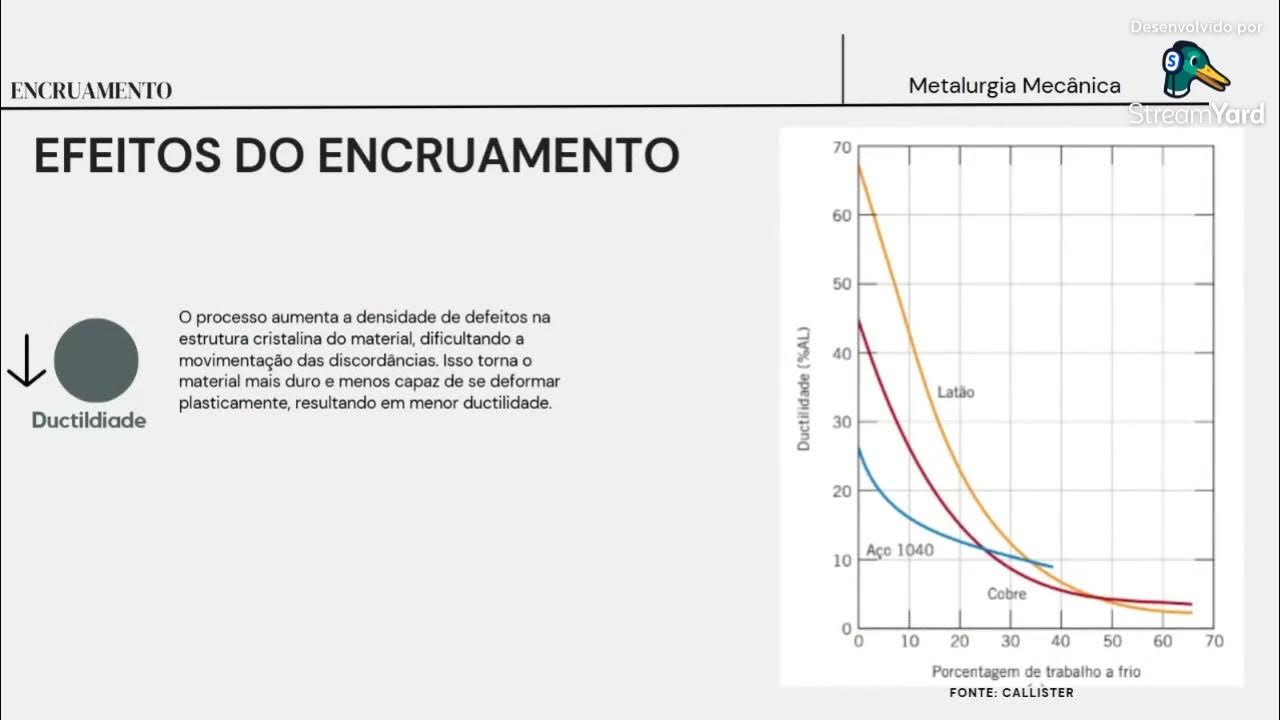

- 😀 The study of dislocations is essential for understanding how they affect the mechanical properties of metals, including their plastic deformation and resistance.

- 😀 There are three main types of dislocations: edge dislocations, screw dislocations, and mixed dislocations, each with distinct characteristics.

- 😀 In edge dislocations, the distortion is centered around the edge of an extra plane, causing a step-like structure on the crystal surface.

- 😀 Screw dislocations involve the formation of a spiral in the crystal lattice, with atoms misaligned along the dislocation line.

- 😀 Mixed dislocations contain both edge and screw components and are commonly found in crystalline materials.

- 😀 The Burgers vector defines the magnitude and direction of dislocation movement and is perpendicular to edge dislocations and parallel to screw dislocations.

- 😀 Dislocations can move along the crystal, forming steps at the crystal surface; this movement is influenced by the applied stress direction.

- 😀 Dislocation motion can be either conservative (along the dislocation plane) or non-conservative (perpendicular to the Burgers vector, causing dislocation climbing).

- 😀 The Frank-Read source mechanism describes how dislocations multiply, with dislocations curving and re-emerging under applied stress, contributing to material deformation.

Q & A

What is the definition of dislocation in metallurgy?

-Dislocation is a linear defect in the crystal structure where several atoms are misaligned, causing distortion in the crystal lattice.

Why is the study of dislocations important in materials science?

-The study of dislocations is important because their formation and movement are key to increasing the mechanical strength and plastic deformation of metals.

What is an edge dislocation, and how does it affect the crystal structure?

-An edge dislocation is a type of dislocation where the distortion in the crystal is centered around the edge of an extra plane. It causes shear stress and leads to a unit step at the end of the dislocation as it moves.

What is the difference between edge dislocation and screw dislocation?

-An edge dislocation involves a distortion along the edge of an extra plane, whereas a screw dislocation involves a spiral pattern in the crystal's lattice planes.

What does the Burgers vector represent in the context of dislocations?

-The Burgers vector defines the magnitude and direction of the dislocation's movement, indicating the extent of lattice distortion.

How does the Burgers vector relate to the movement of edge and screw dislocations?

-For edge dislocations, the Burgers vector is perpendicular to the dislocation line. For screw dislocations, the Burgers vector is parallel to the dislocation line.

What is the difference between conservative and non-conservative dislocation movement?

-Conservative dislocation movement occurs within the plane of the highest atomic density, while non-conservative movement happens perpendicular to the Burgers vector and moves the dislocation to another atomic plane.

What role do precipitates play in dislocation movement?

-Precipitates can hinder dislocation movement, especially when incoherent with the surrounding crystal structure. Dislocations must curve around these precipitates, forming an anchoring ring that blocks further dislocation movement.

What is the Frank-Read source, and how does it contribute to dislocation multiplication?

-The Frank-Read source is a mechanism that generates dislocations. When a dislocation is subjected to applied stress, its ends curve and eventually meet, forming new dislocations that multiply as the process repeats.

How are dislocations observed in materials?

-Dislocations are typically observed using transmission electron microscopy due to their small size, where they appear as lines or forests of dislocations in materials such as titanium alloys.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тариф5.0 / 5 (0 votes)