How to Flare Brake Lines for Your Truck, Car, or SUV

Summary

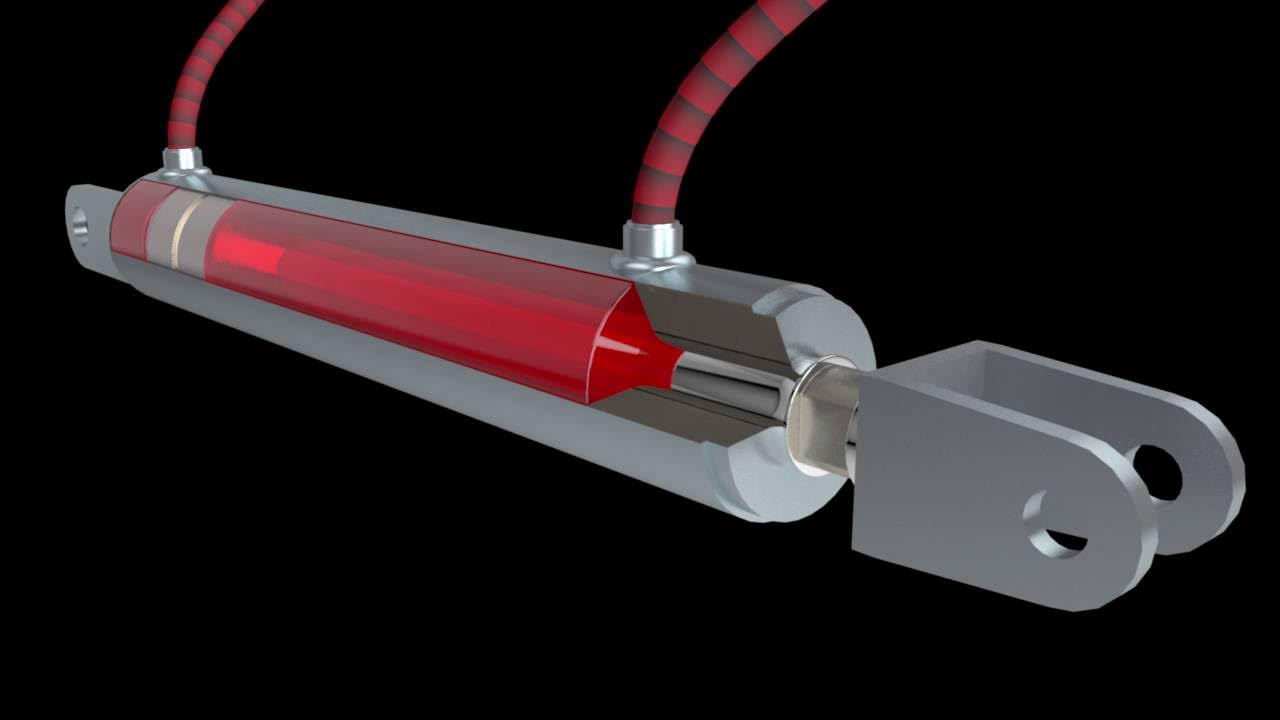

TLDRIn this instructional video, Len from 1AAuto guides viewers through the process of creating double and bubble flares for brake lines, key components for safe and functional braking systems. He demonstrates the tools and techniques necessary to properly flare brake lines, emphasizing the importance of using the correct flare type based on the vehicle's specifications. Len explains why single flares are unsafe, while double and bubble flares provide enhanced strength and safety. The video also covers tips for bending brake lines without causing damage, ensuring optimal brake line performance for DIY repair projects.

Takeaways

- 😀 Avoid using single flares for brake lines, as they are unsafe and can lead to leaks.

- 😀 Double flares are the most common and safest option for most brake line applications.

- 😀 Bubble flares are also safe, but are used for specific vehicle applications.

- 😀 Always check the original brake line fittings to determine the correct flare type for your vehicle.

- 😀 Use a flare tool kit with the correct adapters (e.g., 3/16 or 1/4 inch) for your brake line size.

- 😀 When making a double flare, the brake line should be pressed twice to create a strong, double-thickness seal.

- 😀 Ensure the flare tool is aligned correctly and the brake line is securely positioned before pressing.

- 😀 A bubble flare creates a rounded, bubbled shape at the end of the brake line, used for specific vehicle types.

- 😀 For both types of flares, always clean the flare after finishing to remove any burrs or imperfections.

- 😀 When bending brake lines, be careful not to crimp the line. If it gets crimped, cut and start over.

- 😀 Safety is key—brake lines are under high pressure, so ensure all flares are made correctly to avoid brake failure.

Q & A

What is the difference between a double flare and a bubble flare?

-A double flare is a type of brake line flare where the end of the brake line is folded over and pressed, doubling its thickness for extra safety. A bubble flare, on the other hand, forms a 'bubble' shape at the end of the brake line, typically used in specific vehicle applications.

Why should you avoid making a single flare for brake lines?

-A single flare lacks the necessary strength and safety that a double flare provides. It is more likely to leak and fail, posing a serious safety risk for the brake system.

How do you determine which flare type to use for your vehicle?

-To determine the flare type, examine the original brake line and fittings when replacing or repairing. The type of flare already installed on the vehicle will indicate whether you need a bubble flare or a double flare.

What is the importance of using the correct flare type for a brake line?

-Using the correct flare type ensures a secure and leak-proof connection in the brake system, which is crucial for vehicle safety, especially since brakes operate under high pressure.

What are the typical sizes of brake lines and flaring tools used in this process?

-Common brake line sizes are 3/16-inch and 1/4-inch, though other sizes like 5/16-inch may also be used. Flaring tools typically come with adapters for these sizes.

What tools are necessary for making a double flare on a brake line?

-To make a double flare, you need a brake line, a fitting, a flaring tool kit (including adapters), a pressing tool, and a driving tool to complete the flare process.

How do you prevent damaging a brake line while bending it?

-To avoid crimping the brake line while bending, be careful to make smooth, gradual curves. If the line crimps or forms a sharp angle, cut it off and start over, as it could affect brake fluid flow.

What should you do if the flaring tool is not properly aligned with the brake line?

-If the flaring tool is misaligned, wiggle it gently to ensure it sits parallel to the brake line. Misalignment can result in an uneven flare, which could lead to leaks or failure.

What role does the concave area on a brake line kit play in the flaring process?

-The concave area on the brake line kit is where the brake line sits before being flared. It helps ensure the brake line is aligned correctly for the flare, particularly for a double flare.

Can a bubble flare be used in place of a double flare?

-No, a bubble flare cannot be used as a direct replacement for a double flare. Each type of flare is designed for specific applications, and using the wrong one can compromise the brake system's safety and function.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Car or truck pulling to one side but front end is fine. Tips to identify brake or suspension issue

Anti-Skid & Auto-Brakes - Aircraft Brakes - Airframes & Aircraft Systems #23

Types of Brake in Vande Bharat Express

Brake Hydraulic System Components

Aircraft Systems - 07 - Hydraulic System

Pilihan Komponen Upgrade Rem RCB | Gridoto Tips

5.0 / 5 (0 votes)