Cracking the Kiln | Matte vs. Crystalline Glazes | Ceramic Materials Workshop

Summary

TLDRThis video explores the differences between matte and crystalline glazes in ceramics, emphasizing the importance of firing temperatures and cooling cycles. Crystalline glazes require careful control of peak temperatures and cooling rates to achieve the right balance of crystal size and number, while matte glazes offer a stable, consistent finish. The speaker discusses various firing techniques, such as crash cooling and slow cooling, to influence glaze results. Ideal for ceramic artists, this video provides insights into the complexities of glaze chemistry and the technical aspects of achieving desired glaze effects.

Takeaways

- 😀 Crystalline glazes require precise control over firing temperature and cooling to achieve the desired crystal formation.

- 🔥 Firing too cold leads to an overabundance of small crystals, while firing too hot results in fewer, larger crystals.

- 🌡️ Achieving the perfect number of crystals in crystalline glazes is key to their aesthetic success, and this requires careful temperature management.

- 🔬 Crystalline glazes undergo a specific firing cycle: reaching peak temperature, crash cooling, and then holding at a lower temperature to allow crystal growth.

- 🔄 Matte glazes, in contrast to crystalline glazes, are unaffected by the cooling cycle and will not form crystals in the same way.

- 🕰️ Slow cooling is essential for glazes using calcium and magnesium, as it encourages crystal growth during the temperature drop from 1150°C to 850°C.

- ⚙️ The process of slow cooling can take approximately six hours at a rate of 50°C per hour to achieve optimal crystal growth in certain glazes.

- 📊 The degree of crystal formation in crystalline glazes can vary from firing to firing based on small differences in the cooling process.

- 🌿 Matte glazes maintain consistency regardless of firing conditions, while crystalline glazes are more variable, producing different results with each firing.

- 🎓 Ceramic Materials Workshop offers in-depth online classes and workshops on glaze chemistry and other aspects of ceramics, including a dedicated course on crystalline glazes.

Q & A

What is the difference between matte glazes and crystalline glazes in terms of firing behavior?

-Matte glazes are consistent and unaffected by temperature, producing a smooth, uniform finish. Crystalline glazes, on the other hand, are highly sensitive to firing temperatures and cooling cycles, resulting in varying crystal formation with each firing.

Why is achieving the 'perfect number of crystals' crucial for crystalline glazes?

-For crystalline glazes, achieving the right number of crystals is essential to get the desired visual effect. Too few crystals result in a glassy or smooth surface, while too many lead to an overly textured finish. Firing temperature and cooling rate are critical in determining the crystal size and distribution.

What happens when you fire a crystalline glaze at too high a temperature?

-Firing a crystalline glaze at too high a temperature dissolves the zinc into the glaze, leading to fewer and larger crystals, or no crystals at all, as the glaze becomes more fluid and loses its crystalline structure.

What is the significance of a 'crash cool' in crystalline glazing?

-A 'crash cool' involves rapidly lowering the kiln temperature after reaching the peak temperature to allow crystals to form as the glaze cools. This process is crucial for crystalline glazes to produce the desired crystal formation.

How does the cooling rate affect crystalline glaze formation?

-The cooling rate is vital for crystalline glazes. A slow cooling process allows crystals to grow at the optimal temperature range (around 1150°C to 850°C), enhancing crystal size and distribution. A natural or fast cool may result in little or no visible crystal growth.

What is a typical firing cycle for a slow cool in crystalline glazing?

-A typical slow cool cycle involves bringing the kiln down from a peak temperature (around 1150°C) to about 850°C at a rate of 50°C per hour. This gradual cooling period allows for crystal growth, typically taking about six hours.

How do crystalline and matte glazes differ in their approach to cooling?

-Matte glazes do not require any specific cooling process because they do not form crystals. In contrast, crystalline glazes need controlled cooling (like crash cools or slow cools) to facilitate crystal formation, which is a critical part of achieving the desired glaze texture.

Why are zinc silicate glazes particularly sensitive to firing temperature?

-Zinc silicate glazes are sensitive to firing temperature because they are prone to forming crystals during the cooling phase. At higher temperatures, the glaze becomes more liquid and dissolves more of the zinc, leading to fewer crystals, while lower temperatures encourage over-nucleation and excessive crystal formation.

What is the role of glaze chemistry in achieving a successful crystalline glaze?

-Glaze chemistry plays a significant role in determining the crystal formation in crystalline glazes. The composition of the glaze, including materials like zinc, calcium, and magnesium, influences how crystals grow and how the glaze behaves at different temperatures. Fine-tuning the recipe and firing cycle is essential for optimal crystal growth.

How can the understanding of crystalline and matte glazes benefit ceramic artists?

-Understanding the differences between crystalline and matte glazes allows ceramic artists to make more informed decisions about glaze application, firing cycles, and desired outcomes. Artists can better control texture, color, and surface effects by choosing the appropriate glaze type and firing method.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Da argilla a ceramica - La trasformazione in cottura

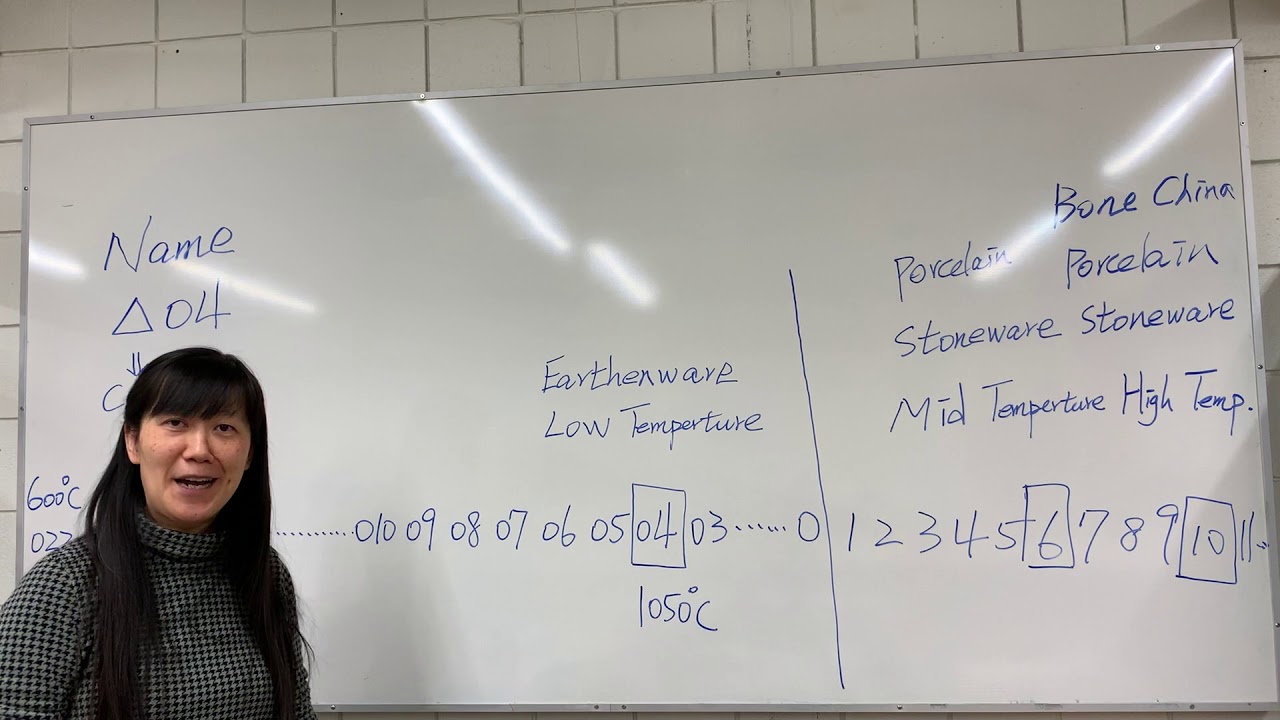

23.13 Name clay and tools, and Information for clay types and temperatures

Why Porcelain Is So Expensive | So Expensive | Business Insider

La Ceramica per Principianti in meno di 10 MINUTI. Video Tutorial sulla Ceramica - SUPER FACILE!!!

Material Teknik Keramik Kuliah ke12 Online

Refrigerasi-01

5.0 / 5 (0 votes)