PLC Learning Series - What are PLC Inputs?

Summary

TLDRThis video explains the essential concepts of PLC (Programmable Logic Controller) inputs, focusing on how digital and analog sensors are wired and integrated into PLC systems. It covers the distinction between sinking and sourcing inputs, how push buttons, PNP, and NPN sensors are connected, and troubleshooting methods for verifying input functionality. The guide also explores analog inputs, such as ultrasonic sensors, and demonstrates how input readings are processed by the PLC. Ideal for learners and industrial automation professionals, the video provides a clear and practical understanding of PLC input wiring and configurations.

Takeaways

- 😀 PLC inputs are physical devices connected to the PLC that provide critical information for controlling outputs, such as push buttons, switches, and sensors.

- 😀 Inputs are isolated from the CPU to prevent damage, allowing the PLC to continue functioning even if an input fails.

- 😀 Digital inputs are binary, either ON or OFF, whereas analog inputs provide a continuous range of values, such as distance measured by sensors.

- 😀 Sinking inputs have a common (ground) at zero volts, while sourcing inputs have a positive voltage on the common point.

- 😀 Mixing sinking and sourcing inputs on the same PLC common point can create a short circuit and damage the PLC input system.

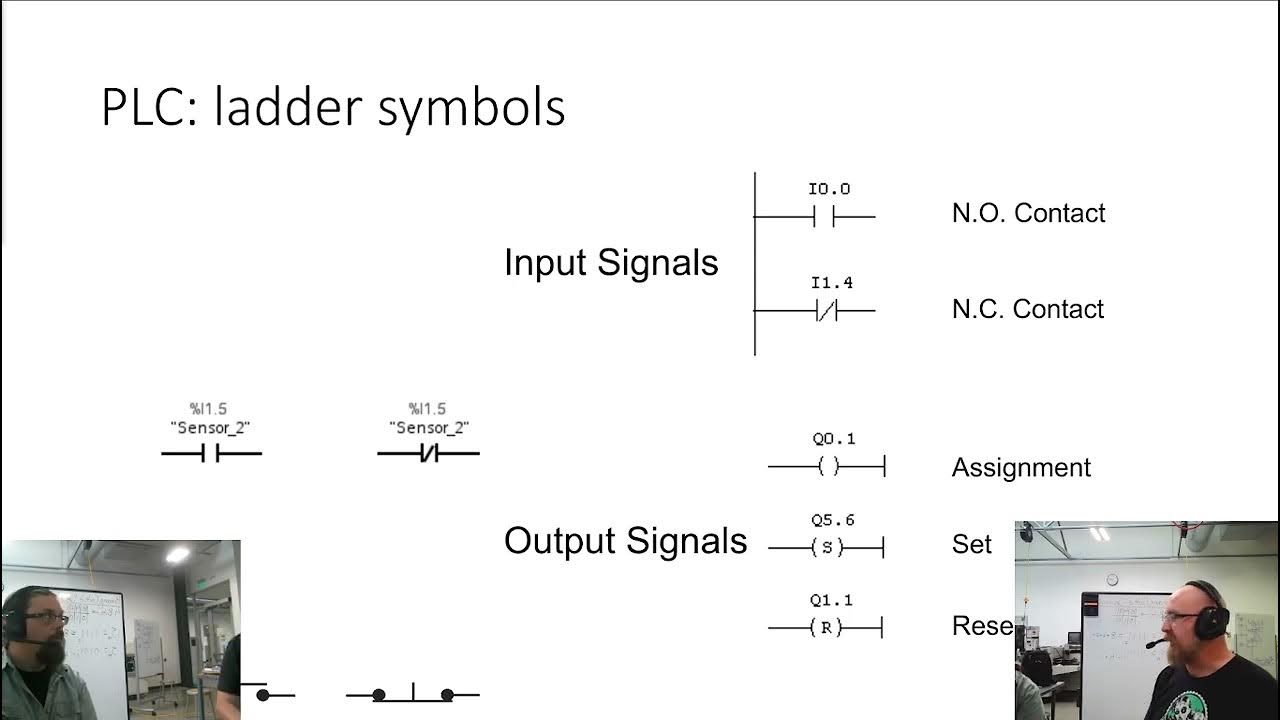

- 😀 Normally open (NO) push buttons provide no voltage when unpressed, while normally closed (NC) push buttons have voltage applied when unpressed.

- 😀 Sensors like NPN and PNP refer to the type of transistor output: NPN is sinking (grounding) and PNP is sourcing (providing voltage).

- 😀 It is important to refer to manufacturer specifications to correctly wire sensors and PLC inputs to avoid wiring errors or damage.

- 😀 Troubleshooting PLC inputs involves measuring the voltage across input points with a meter to confirm whether the sensor or input is functional.

- 😀 Analog sensors, like ultrasonic sensors, output a continuous voltage signal that can be scaled to represent a physical measurement, like distance.

- 😀 Wiring practices should ensure that all inputs on a PLC are either sinking or sourcing, as mixing can result in incorrect behavior or damage to the PLC.

Q & A

What is the primary function of PLC inputs?

-PLC inputs provide information to the programmable logic controller (PLC) about the state of physical devices, such as push buttons, switches, and sensors. This information is used to control the PLC's output actions.

What are the two main types of PLC inputs?

-The two main types of PLC inputs are digital (discrete) inputs and analog inputs. Digital inputs represent binary on/off states, while analog inputs measure a range of values.

What does the term 'sinking input' mean in the context of PLC wiring?

-In a sinking input configuration, the load is connected between the input point and a common point at zero volts. The input pulls the current to ground, effectively 'sinking' the current.

How does a 'sourcing input' differ from a 'sinking input'?

-A sourcing input has a common point connected to a positive voltage (e.g., +24V), and the input receives current from the sensor. In contrast, a sinking input has a common point at zero volts, and the input pulls current from the sensor to ground.

What is the importance of isolation between PLC inputs and the CPU?

-The isolation protects the PLC's CPU by preventing damage if an input is destroyed. It ensures that the PLC can continue functioning even if one input fails, and the damaged input can be replaced or reprogrammed without affecting the rest of the system.

What are normally open (NO) and normally closed (NC) inputs, and how do they work?

-Normally open (NO) inputs do not have voltage until triggered, such as when a start button is pressed. Normally closed (NC) inputs have voltage present unless triggered, such as when a stop button is pressed. The state of these inputs changes based on the action taken.

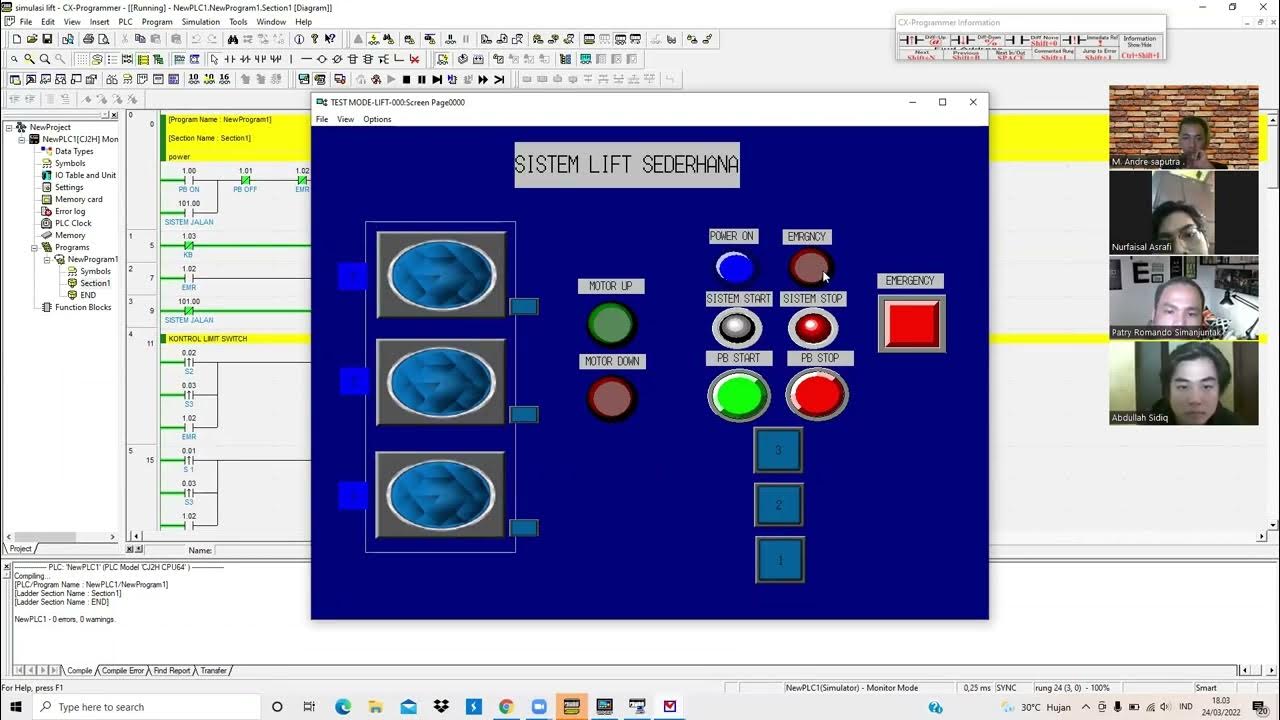

What is the role of the operator's Human-Machine Interface (HMI) in PLC input systems?

-The HMI serves as a way for operators to interact with the PLC system. It can provide input signals to the PLC, such as buttons or switches, which in turn control the PLC's outputs based on the operator's actions.

What is the significance of using PNP and NPN sensors with PLC inputs?

-PNP (positive-negative-positive) and NPN (negative-positive-negative) sensors determine how the PLC input is wired. PNP sensors are often used in sourcing configurations, while NPN sensors are used in sinking configurations. It is important to correctly wire and program the PLC to match the sensor type to avoid electrical faults.

Why is it critical not to mix sourcing and sinking inputs on the same PLC common point?

-Mixing sourcing and sinking inputs on the same common point can create a short circuit, damaging the PLC input and potentially rendering the system inoperable. It's essential to follow proper wiring guidelines for the entire system.

How can a multimeter be used to test PLC inputs?

-A multimeter can be used to measure the voltage across the load connected to a PLC input. If the input is ON, the voltage should read around 24V; if OFF, the voltage should be 0V. This helps troubleshoot and verify if the input or sensor is functioning correctly.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

Source & Sink Concept in PLC । What is Sourcing & Sinking in PLC । PLC मैं Sink और Source कनेक्शन ?

DASAR PEMOGRAMAN PLC - SIMBOL - SIMBOL DASAR PLC

Simulasi Lift sederhana 3 Lantai dengan menggunakan PLC pada CX-Programmer dan CX-Designer

SysAp 7 1 Ladder Logic

plc

Example PLC: EATON EASY Intelligent Relay (Full Lecture)

5.0 / 5 (0 votes)