Apa itu HMI?

Summary

TLDRThis video introduces the concept of Human-Machine Interface (HMI) in the industrial sector, explaining its role in integrating humans with complex technological systems. Using examples like ATMs, the video highlights how HMIs enable operators to monitor and control machinery through screens and buttons, improving efficiency and reducing errors. It discusses the software and hardware components necessary for effective HMI operation, including the importance of communication protocols between HMIs and PLCs. Viewers will gain insights into how HMIs simplify industrial processes, enhance reliability, and support troubleshooting, making them essential tools in modern manufacturing.

Takeaways

- 😀 HMI stands for Human-Machine Interface, essential for integrating humans with complex technological systems.

- 😀 ATMs are a common example of HMI used in everyday life.

- 😀 In industrial settings, HMI is crucial for controlling and monitoring machinery operations.

- 😀 HMI simplifies complex variables, presenting data like temperature and process stages in an accessible format.

- 😀 Real-time data on HMIs enhances decision-making and operational efficiency.

- 😀 HMI can be linked to Programmable Logic Controllers (PLC) for efficient troubleshooting.

- 😀 Each HMI system uses specialized software that must be programmed by engineers.

- 😀 Compatibility between HMI and PLC is vital for effective communication and functionality.

- 😀 Common communication protocols for HMI include Modbus, Ethernet, and Profibus.

- 😀 HMI technology can significantly improve productivity and reduce errors in industrial processes.

Q & A

What does HMI stand for?

-HMI stands for Human-Machine Interface.

Can you provide a common example of HMI in everyday life?

-An ATM machine is a common example of HMI that people use regularly.

What is the primary function of an HMI in industrial settings?

-In industrial settings, HMIs are used to control and monitor machines and systems.

How does HMI simplify complex industrial systems?

-HMI simplifies complex systems by presenting information and controls in an easy-to-understand format on screens.

What types of data can an HMI display?

-HMIs can display real-time data such as temperature, pressure, process stages, and material counts.

What role does software play in HMI systems?

-Software allows engineers to design the HMI interface, specifying what operators see and how they interact with the system.

What are some common communication protocols used in HMI systems?

-Common communication protocols include Modbus, Ethernet/IP, and Profibus.

Why is compatibility between HMI and PLC important?

-Compatibility is crucial because the HMI and PLC need to communicate effectively to monitor and control processes.

How does HMI improve efficiency in industrial operations?

-HMI reduces errors, increases efficiency, and enhances the reliability and maintainability of industrial systems.

What is a potential challenge in programming an HMI?

-A challenge in programming an HMI is ensuring that all inputs and outputs are correctly addressed for communication with the PLC.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

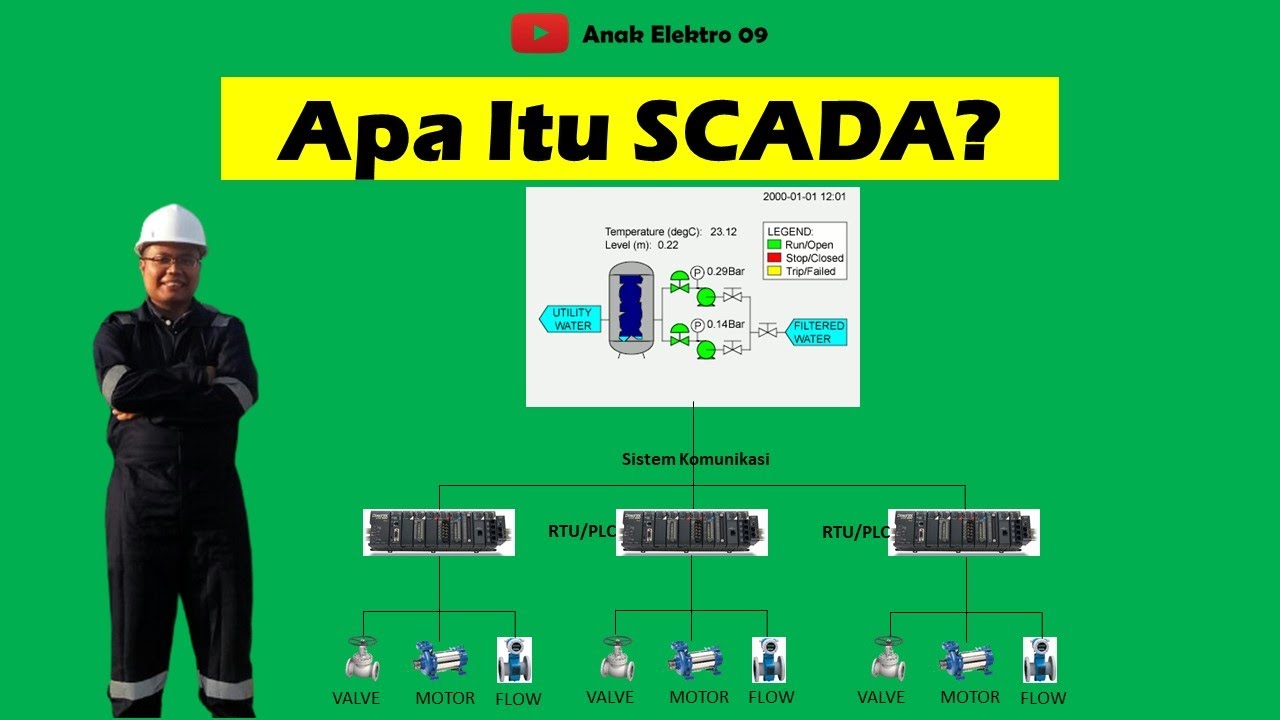

Pengenalan SCADA (Supervisory Control And Data Acquisition)

Machine Learning | What Is Machine Learning? | Machine Learning Basics | 2023 | Simplilearn

PLC HMI Training Video for Automatic Door Open and Close System

What are the Differences between DCS and SCADA?

Pattern Recognition: What & Why

Sistem Pakar Penjelasan dan Contoh | Artificial Intelligence

5.0 / 5 (0 votes)