Die Casting

Summary

TLDRThis video explains the die-casting process in a straightforward manner. It details each step, starting with the preparation of the mold and tools, followed by the injection of molten metal into the closed mold. The process includes compensating for shrinkage, applying pressure until the metal solidifies, and ejecting the finished parts from the mold. Finally, it mentions the removal of sprues and the readiness of the die-cast parts for further processing. The video invites viewers to explore more casting processes on the channel.

Takeaways

- 🔧 The die-casting process starts with placing the mold and tools on the machine.

- 🔥 Molten metal is injected into the closed mold to fill the cavity.

- 💧 Extra material is included to compensate for shrinkage during cooling.

- ⏳ The plunger holds pressure until the metal has fully solidified.

- 🚪 Once cooled, the die can be opened to access the cast parts.

- 🔄 Pins are used to eject the parts from the mold after opening.

- ✂️ Sprues remain attached to the parts and must be removed afterward.

- 📦 The die-cast parts are then ready for the next stages of production.

- 🎥 The video encourages viewers to explore other casting processes on the channel.

- 👀 The die-casting method is efficient for producing precise and complex shapes.

Q & A

What is the first step in the die-casting process?

-The first step is placing the die-casting mold and tools on the machine.

How is the molten metal introduced into the mold?

-The molten metal is injected into the closed die to fill the cavity.

Why is extra material forced into the cavity during the process?

-Extra material is forced into the cavity to compensate for shrinkage that occurs during the cooling process.

What happens after the molten metal is injected into the mold?

-The plunger is held under pressure until the metal solidifies.

When can the die be opened?

-The die can be opened once the metal has cooled and solidified.

What role do the pins play in the die-casting process?

-The pins are used to eject the parts from the mold after the die is opened.

What happens to the sprues after the parts are ejected?

-The sprues are still attached to the parts and need to be removed after ejection.

What can be done after the individual die-cast parts are ready?

-The individual die-cast parts are prepared for the next stages of production.

What is the importance of holding the plunger under pressure?

-Holding the plunger under pressure ensures that the molten metal fills the cavity completely and solidifies properly.

Where can viewers find more information about casting processes?

-Viewers can check out other casting processes on the channel.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

What Is Casting? 11 Types of Casting Processes Explanation

5 Tips for Working With Aluminium HIGH PRESSURE DIE CASTING | Explained - Serious Engineering: Ep 28

2 Ways to Screen Mirroring in Mi TV | Mi Android TV | Screencast

How Die Casting Aluminum Works - How It's Made

What Are The Common Types Of Metal Casting Process In Engineering and Industry?

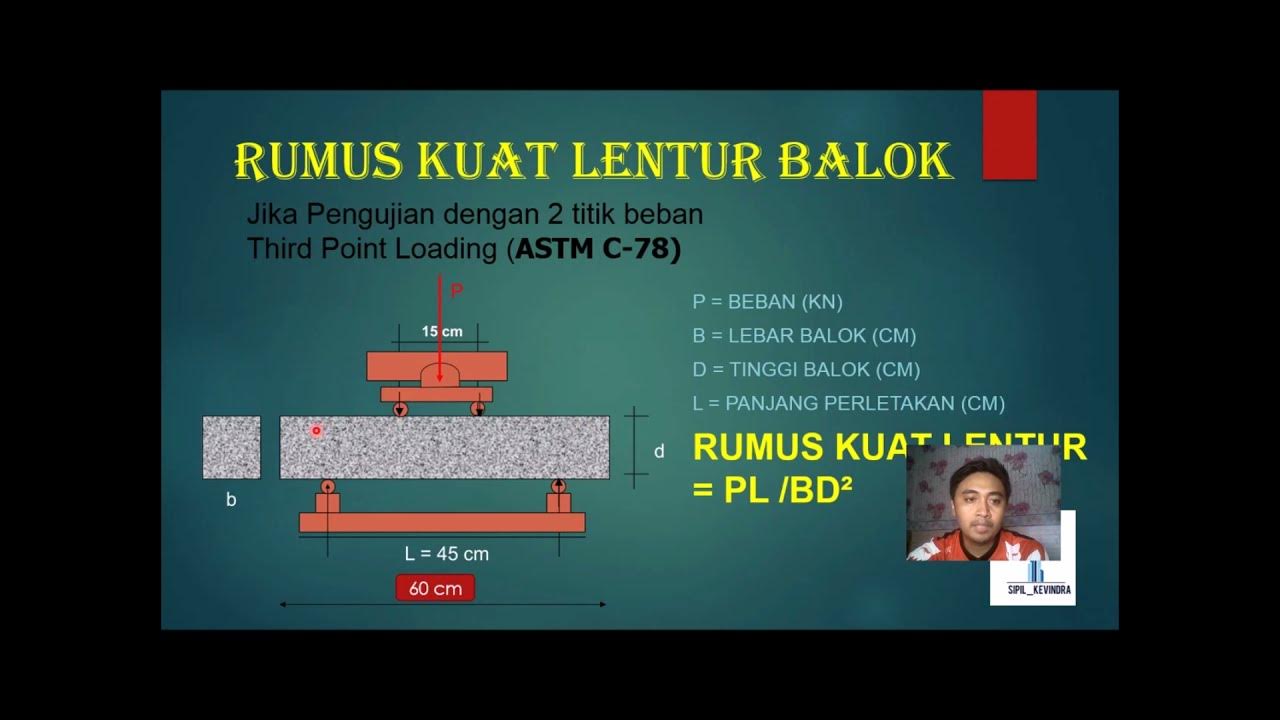

PENGUJIAN TES KUAT LENTUR BETON

5.0 / 5 (0 votes)