Explore ETAP Power System Monitoring and Simulation (PSMS™)

Summary

TLDRThis session showcases the ETAP Power Management System, highlighting its monitoring and simulation capabilities. It demonstrates how digital twin analysis with live data can predict system behavior, optimize operations, and enhance situational intelligence for electrical systems across various industries. The system's scalability and integration with SCADA for real-time monitoring and control are also emphasized.

Takeaways

- 🔌 **Overview of ETAP Power System**: The session provides an overview of the ETAP power system, emphasizing its monitoring and simulation capabilities.

- 🌐 **Digital Twin Analysis**: ETAP BSMS uses digital twin analysis with live data to offer predictive simulation features.

- 🛠️ **Interface with Electrical Devices**: ETAP demonstrates how it interfaces with typical electrical devices to collect live data.

- 📊 **Powerful HMI Views**: Users can create simple yet powerful HMI views to monitor and operate all electrical assets using the digital twin model.

- 🔍 **Situational Intelligence**: ETAP's situational intelligence feature offers high-level insights into the electrical system's state and behavior before operator actions.

- 🔌 **Continuous Evolution of Electrical Model**: ETAP allows for the continuous evolution of the electrical model, enhancing its accuracy and reducing validation time.

- 🔄 **Data Collection Server**: ETAP uses a data collection server capable of handling various communication protocols to interface with electrical devices.

- 📈 **Predictive Simulation**: ETAP's predictive simulation feature uses live data to estimate power flow across the system, including areas without metering.

- 🛡️ **Electrical Validation**: ETAP validates monitored data against the electrical model to ensure accuracy and highlight discrepancies.

- 🔄 **Scalability and Modularity**: ETAP's solution is scalable and modular, allowing for deployment from simple systems to complete enterprise solutions.

- 👥 **User Access Control**: ETAP includes tools for secure access, with administrators able to restrict unauthorized access and limit user roles.

Q & A

What is the primary purpose of the Etap Power Management System?

-The primary purpose of the Etap Power Management System is to monitor, operate, and simulate electrical systems for a wide range of mission-critical industries using a digital twin model.

What does the digital twin model in Etap Power Management System offer?

-The digital twin model allows users to create powerful but simplistic HMI views to monitor and operate all electrical assets, and it combines the intelligence of the digital twin simulation to reproduce backnotes and analyze events to understand the behavior of the electrical system.

How does Etap BSMS interface with electrical devices?

-Etap BSMS interfaces with electrical devices by adding a data collection server that uses existing infrastructure to communicate with devices using common communication protocols such as IEC 61850, Modbus, etc.

What is the benefit of using digital twin analysis with live data?

-Using digital twin analysis with live data provides benefits such as situational intelligence, predictive simulation, and the ability to deploy electrical SCADA using the digital twin model, offering unique insights on the state and behavior of the electrical system.

How can the Etap Power Management System be scaled for enterprise solutions?

-The Etap Power Management System can be scaled for enterprise solutions with its robust client-server architecture, which enables deployment and support for multiple clients, from dedicated workstations to secure web clients.

What is the role of the Etap Scan Integrator tool in the system?

-The Etap Scan Integrator tool is used to create device models that define typical measurements for a device, which can then be linked to all Etap components sharing the same measurements, reducing the time spent on integration.

How does the predictive simulation feature in Etap PSMS work?

-The predictive simulation feature leverages online data and the digital twin to create several measurements to estimate the power flow across the rest of the model, including areas where metering is not possible.

What is the purpose of the situational intelligence feature in Etap PSMS?

-The situational intelligence feature provides operators with high-level insights into the response of the electrical system before any operator action, helping to improve decision-making and system reliability.

How does Etap PSMS ensure secure access to the system?

-Etap PSMS ensures secure access through high availability, integration of secured managed access, and the ability to restrict unauthorized access and limit user roles and actions.

What are the advantages of using Etap PSMS over a typical SCADA system?

-Etap PSMS offers advantages such as continuous evolution of the digital twin for improved model accuracy, integration of the digital twin and SCADA solution under one platform, predictive simulation for better insights into system behavior, and tools like situational intelligence for improved operator confidence.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифПосмотреть больше похожих видео

eTraX™ – Design, Planning & Operation of Rail Traction Systems

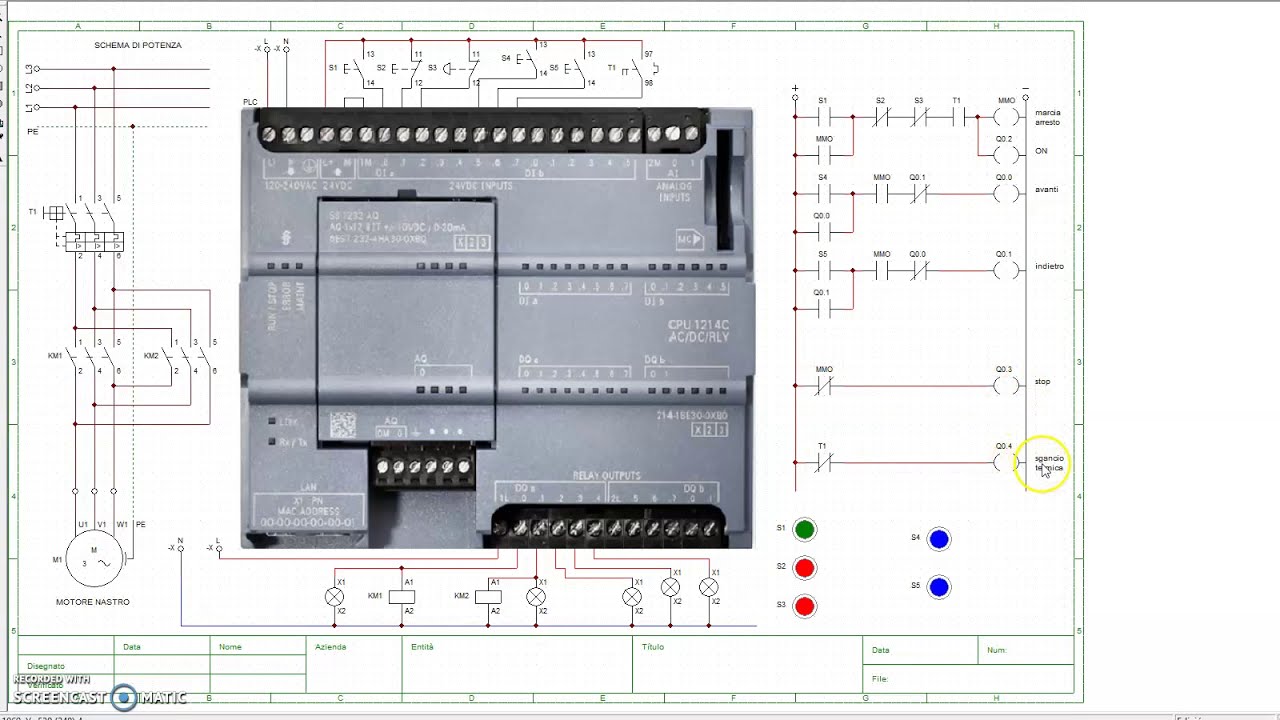

Teleinversione motore trifase con PLC, schema potenza, pilotaggio e ladder simulazione

Transformer X/R - Ratio

GLM-4.5 is Insane! ChatGPT5 is in trouble

ETAP Software explained in 5 Minutes

OxBlue - CCTV designed for construction and powered by AI technology at Digital Construction Week

5.0 / 5 (0 votes)