CHARPY IMPACT TEST

Summary

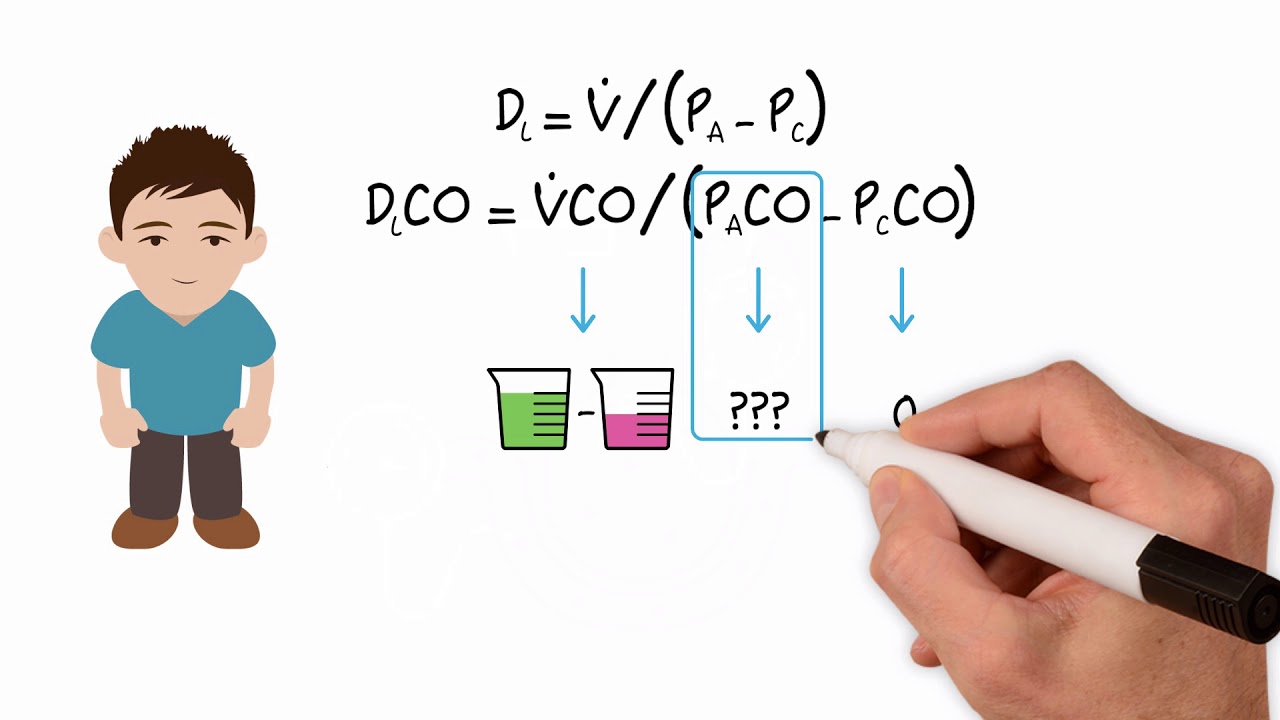

TLDRThis video script details a Charpy impact test, a crucial method for assessing metal properties by measuring its resistance to impact. The test involves striking a standardized specimen to determine its toughness and the material's transition temperature from ductile to brittle. Conducted at various temperatures, the test uses equipment like a pendulum tester, a profile projector, and a thermocouple. The script explains the process of specimen preparation, dimension measurement, and conducting tests at different temperatures, highlighting the impact of temperature on metal toughness and fracture patterns observed in the test results.

Takeaways

- 🔧 The Charpy impact test is conducted to determine the toughness of metals and identify the transition temperature where metals change from ductile to brittle behavior.

- 📏 The test specimen must adhere to the ASTM E 23 standard, with specific dimensions of 10mm x 10mm x 55mm and a V-notch of 45° angle and 2mm depth.

- 🛠️ Equipment required for the test includes a pendulum impact tester, a profile projector for measuring specimen dimensions, and a thermocouple or thermometer for temperature measurement.

- ❄️ The test is performed at various temperatures to ascertain the material's ductile-to-brittle transition temperature, using cooling media such as dry ice and alcohol.

- 🔢 The impact tester's pendulum is set to zero before each test, and the specimen is placed between the anvils to ensure accurate and consistent results.

- 📊 The impact energy absorbed by the specimen is measured in Joules, with the results indicating the material's toughness at different temperatures.

- 📉 As the test temperature decreases, the impact energy absorbed by the metal specimen typically decreases, indicating a transition from ductile to brittle behavior.

- 🧩 The fracture patterns observed after the test can reveal the nature of the material's failure, with ductile failures showing significant deformation and brittle failures exhibiting a flat, non-deformed surface.

- 📋 The test results, including impact energy and fracture patterns, can be recorded and analyzed using applications like Excel to understand the material's performance across a range of temperatures.

- 🔬 The Charpy impact test provides valuable insights into a metal's toughness and its ability to withstand impacts, which is crucial for applications where materials may be subjected to low temperatures.

Q & A

What is the purpose of impact testing in materials science?

-Impact testing is conducted to determine the toughness of a metal material, specifically to understand the changes in its properties under different temperatures.

What are the two types of impact tests mentioned in the script?

-The two types of impact tests mentioned are Charpy and ISO tests.

What is the standard specimen size for impact testing according to the script?

-The standard specimen size for impact testing is 10 mm by 10 mm in cross-section and 55 mm in length.

What is the significance of the notch in the impact test specimen?

-The notch in the impact test specimen is crucial as it influences the material's fracture toughness. The standard angle of the notch is 45°, the depth is 2 mm, and the radius at the bottom is 0.25 mm.

What is the purpose of the radius measurement in the notch of the specimen?

-The radius measurement in the notch is important to ensure the accuracy of the impact test results. If the radius deviates from the standard, the toughness values obtained will not be precise.

What tools are used to measure the dimensions of the specimen before the impact test?

-The tools used to measure the dimensions of the specimen include a profile projector, vernier caliper, and a stem center punch.

What is the role of the thermocouple or thermometer in the impact testing process?

-The thermocouple or thermometer is used to measure the temperature during the impact test, as the test is conducted at various temperatures to determine the material's transition temperature.

What is meant by 'transition temperature' in the context of impact testing?

-Transition temperature refers to the point at which a metal changes its properties from ductile to brittle or vice versa.

How is the impact tester machine set up for testing at different temperatures?

-The impact tester machine is set up with a pendulum striker that swings to impact the specimen. The machine is calibrated to measure the energy absorbed during the fracture, which is indicated by the movement of the pendulum.

What is the procedure for conducting an impact test at low temperatures?

-For low-temperature impact tests, a cooling medium is prepared, often a mixture of alcohol and dry ice, to reduce the temperature of the specimen. The specimen is then submerged in this medium for a specified time before testing.

How does the fracture pattern of a metal change with decreasing temperature according to the script?

-As the temperature decreases, the fracture pattern transitions from ductile with significant lateral expansion to a more brittle fracture with minimal lateral expansion and a flat, featureless surface.

Outlines

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифMindmap

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифKeywords

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифHighlights

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тарифTranscripts

Этот раздел доступен только подписчикам платных тарифов. Пожалуйста, перейдите на платный тариф для доступа.

Перейти на платный тариф5.0 / 5 (0 votes)