Installing a lathe for the machine shop and leveling

Summary

TLDRIn this video, the host tackles the challenge of leveling a lathe machine in his workshop. He constructs a base using high-strength steel filled with concrete and rebar, which is then used to raise and stabilize the lathe. The process involves careful leveling, ensuring the machine's headstock to tailstock alignment, and creating a slight slope for sump pump drainage. The host also emphasizes safety, precision, and the importance of revisiting the leveling after the machine has been in use to account for any shifts due to temperature changes and settling.

Takeaways

- 🛠️ The video is about a DIY project to level a lathe machine by creating custom riser blocks with concrete, rebar, and HSS steel.

- 🏗️ The lathe is initially on a pallet which provides an extra six inches of height beneficial for the tall user, but needs to be leveled properly for optimal use.

- 🔨 High Strength Structural Steel (HSS) is used in the project, not to be confused with High-Speed Steel, and is part of the riser block construction.

- 📦 A toe jack on loan from a subscriber is used to lift the lathe, highlighting the importance of safety and backup plans when lifting heavy machinery.

- 🧱 The concrete riser blocks are filled with rebar for strength, and an attempt is made to create a smooth surface using foam for a mold.

- 🎨 The concrete blocks are painted after curing for at least 48 hours, with an emphasis on cleanliness to prevent damage to the lathe's leveling surface.

- 🔧 The leveling process involves adjusting the machine's feet and using a machinist level to ensure the lathe has a slight slope for swarf collection.

- 🔩 The importance of cleanliness and careful adjustment is stressed, especially when dealing with precise machinery like a lathe.

- 🛑 The video provides a disclaimer about safety, recommending the use of protective gear when operating tools like a wire wheel.

- 🔄 The leveling process may need to be revisited after the machine has been in use and the concrete has fully settled, suggesting a maintenance interval.

- 🔗 Additional resources are provided for viewers to learn more about leveling lathes, emphasizing the value of checking information from multiple sources.

Q & A

What problem is the narrator trying to solve in the video?

-The narrator is trying to solve the problem of the lathe still sitting on its original pallet, which is inconvenient for its use.

Why is the lathe's height an advantage for the narrator?

-The lathe's height is an advantage because the narrator is 6'5", and the extra six inches provided by the pallet makes it more comfortable for him to use the machine.

What is the purpose of using HSS steel in the project?

-The HSS steel, which stands for high strength structural steel, is used to create a base for the lathe, filled with concrete and rebar, to lift and stabilize it.

What tool is used to lift the lathe in the video?

-A toe jack is used to lift the lathe, which is on loan from one of the narrator's subscribers.

Why is it important to crib the lathe during the lifting process?

-Cribbing the lathe ensures stability and safety during the lifting process, as it provides backup support in case the toe jack fails.

What is the purpose of using concrete in the base of the lathe?

-The concrete acts as a buffer to reduce the transmission of frequency and vibration from the floor to the machine, improving its operation.

How does the narrator plan to secure the rebar and L brackets in the concrete base?

-The narrator plans to slide the rebar and L brackets into the concrete and then tap them into place with a hammer to ensure they are secure and level.

What is the narrator's approach to leveling the lathe?

-The narrator uses a machinist level and adjusts the machine's feet by turning screws to create a slight slope, ensuring that any waste runs from the front to the back into a sump pump.

Why does the narrator suggest revisiting the leveling process after a few weeks?

-The narrator suggests revisiting the leveling process because the concrete may settle over time, and the machine's weight distribution could shift after it has been used and heated up.

What additional resources does the narrator recommend for leveling a lathe?

-The narrator recommends checking out the YouTube channels of Inherited Machinery and two other sources for detailed instructions and to fact-check the process.

How does the narrator ensure the leveling process is accurate and precise?

-The narrator uses a clean and accurate machinist level, makes small adjustments to the machine's feet, and checks the level multiple times to ensure precision.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Tutorial Mesin frais bagi pemula

Cara mengoperasikan mesin bubut. (Tehnik dasar)||How to operate a lathe. (Basic technique)

ALL NEW WOBL BOSSES LEAKED & THESE NEW FIGHTS LOOK LIKE A DREAM & NIGHTMARE! [Solo Leveling: Arise]

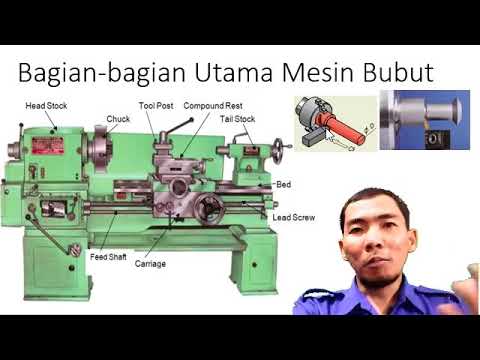

MENGENAL BAGIAN MESIN BUBUT

Latihan Soal Teknik Mesin/Pemesinan #mesin bubut

Bagian - bagian utama Mesin Bubut

5.0 / 5 (0 votes)