PSC Compressor Diagnosis

Summary

TLDRIn this comprehensive guide, the process of diagnosing and testing a split-phase compressor is explained in detail. The steps include ensuring the system is powered off, checking the compressor windings for continuity, and using a megger for insulation resistance. The capacitor's performance is tested, and amperage checks are done to detect any issues, such as a bad capacitor or faulty windings. Additionally, the video explores how to handle overloads, voltage readings, and the importance of timely maintenance to prevent further damage to the compressor and motor. This thorough procedure ensures effective diagnostics and maintenance of HVAC systems.

Takeaways

- 😀 Ensure the power is off before beginning any work on the compressor. Check both the line and load sides for voltage to confirm everything is de-energized.

- 🔧 Use a multimeter to test the compressor windings for resistance. The sum of the resistance from the common to the start winding and common to the run winding should be close to the specified value.

- ⚡ When checking for insulation resistance, use a megger to ensure no resistance to ground. A reading of over 100 Megohms indicates good insulation.

- 📊 To test the capacitor, switch the multimeter to capacitance mode and verify the capacitor’s values against the rated specifications. The value should be within a 6% tolerance.

- 🔌 Testing the compressor’s amperage can help diagnose issues. If it draws zero amps on the start winding, this could indicate a bad capacitor or an open start winding.

- 🔥 The compressor may enter an internal overload if there’s a problem, especially with a faulty capacitor. Overloading could result in a thermal shutdown.

- 🛠️ If the compressor does not start properly, disconnect the start winding to simulate a bad run capacitor. This will cause the compressor to thermal overload, showing a potential issue.

- 💡 A compressor’s locked rotor amps (LRA) should be checked. A reading below the rated LRA indicates that the compressor isn’t physically seized and can still operate normally.

- 🔍 Line voltage should be monitored throughout the system. Voltage readings on the load side should match the line side to ensure proper functionality of the contactor.

- ⚠️ Pay attention to any voltage drops, especially across contactor connections. If the contactor is faulty, it could cause issues with the voltage supply to the compressor.

Q & A

What is the first step in the compressor diagnostic process?

-The first step is to pull the disconnect switch to ensure the system is powered off before proceeding with any tests.

How do you verify that the system is powered off?

-You use a voltage meter to check the line side and load side for any voltage. The readings should be zero volts, indicating that the system is powered off and safe to work on.

What does the megger test do, and why is it important?

-The megger tests for insulation resistance by applying a 1000-volt test and checking for any leakage to ground. It ensures the compressor's windings are not shorted to ground, which would cause failure.

What should you look for when checking the compressor windings with an ohmmeter?

-When checking the windings, you should measure the resistance between common to run and common to start. The readings should add up to the value from start to run, with a tolerance of about 1/10th of an ohm.

Why is the capacitor test crucial in this process?

-The capacitor test checks if the capacitor is within its rated capacitance range. A bad capacitor can prevent the compressor from starting or running properly, leading to system failure.

What is the difference between a 'locked rotor' condition and a functioning compressor?

-A locked rotor condition occurs when the compressor motor is physically seized, causing it to draw high amperage (locked rotor amps). A functioning compressor will draw less amperage and run normally.

How do you diagnose a bad start capacitor?

-To diagnose a bad start capacitor, disconnect the start winding and try to start the compressor. If the compressor doesn't start and the overload trips, it may indicate a failed capacitor or start winding.

How can you simulate a mechanical issue with the compressor in this diagnostic process?

-You can simulate a mechanical issue by intentionally disconnecting components like the start winding, which would prevent the compressor from starting and trigger the internal overload protection.

Why is it important to check the line and load voltages across the contactor?

-Checking the line and load voltages across the contactor ensures that the contactor is closing properly and there is no voltage drop that would affect the compressor's operation.

What should you do if the compressor draws zero amperage on the start winding?

-If the compressor draws zero amperage on the start winding, it indicates an open start winding or a faulty capacitor. Further investigation is needed to confirm the issue.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

website testing tutorial for beginners (web application) - software testing - manual - testingshala

Macam-macam NDT (Non Destructive Test)

How to Play Like an AZIR MAIN! - ULTIMATE AZIR GUIDE

How To File GSTR9C Annual Return 2023-24 | filing of GSTR9C for fy 2023-24 | GSTR9C filing

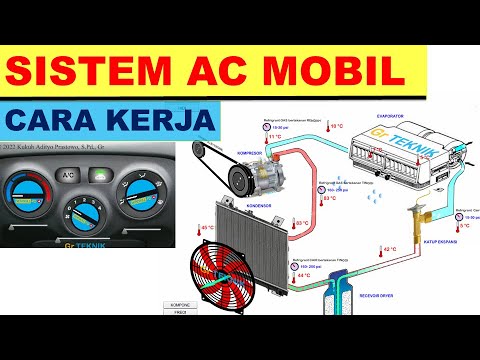

cara kerja sistem ac mobil

Split Testing: How The Top Organic Dropshippers Are Going Viral Consistently

5.0 / 5 (0 votes)