Mecanização Agrícola - Parte II

Summary

TLDRThis video walks through the process of adjusting a seed planter machine for optimal performance. Starting with the adjustment of the tank, the machine is calibrated with the disk and gear for accurate seed planting. Using a perimeter measurement of the drive wheel, the video demonstrates how to count seed drops and adjust gear settings to meet specific seed requirements. The machine is adjusted to ensure the right number of seeds are planted per hectare, with particular focus on gear regulation and avoiding slippage. The importance of checking the machine's manual for the correct settings is emphasized for the farmer.

Takeaways

- 😀 Machine calibration should be done with the machine stopped at the point of operation (pom) to ensure easier field work.

- 😀 Initial disk adjustments can be validated in the field, though minor adjustments may still be needed during actual use.

- 😀 The first step in the calibration process is to count the seed and determine the most appropriate gear for planting.

- 😀 Measuring the perimeter of the drive wheel is essential to accurately track the distance moved by the machine during operation.

- 😀 The drive wheel perimeter is calculated using a string and tape measure, which simplifies the measurement process.

- 😀 A full rotation of the wheel corresponds to the machine moving a specific distance (e.g., 10 turns = 26 meters), which helps calculate seed drop accurately.

- 😀 It's important to mark the drive wheel to track rotations and ensure consistent seed fall measurement.

- 😀 Seed counting should begin after a few rotations to ensure the seed drop is measured correctly, avoiding inaccuracies during the initial rotations.

- 😀 In this case, a spacing of 70 cm between rows and a target of 60,000 plants per hectare is required, with adjustments based on seed germination rates.

- 😀 Gear adjustments are necessary to ensure the right number of seeds fall within the required space. In this case, fewer seeds were needed to meet the target.

- 😀 A gear box is used to simplify adjustments, allowing for finer control over the speed of the disk rotation to match the desired seed count.

- 😀 Calibration is critical to avoid over-planting, and proper gear settings will help ensure the correct amount of seed is planted per area.

- 😀 Farmers should consult the manual for the appropriate settings based on their machine's gear type and disc specifications to avoid errors.

Q & A

Why is it important to adjust the machine with it stopped at the pom?

-Adjusting the machine with it stopped at the pom makes the work easier in the field. It allows for better initial adjustments before validating them in the field, reducing the need for extensive field adjustments.

How does adjusting the disk impact the process?

-Adjusting the disk is a crucial part of the process as it ensures proper seed distribution. The disk's adjustments are important to optimize the machine's efficiency in planting.

What is the purpose of counting the seed and checking the appropriate gear?

-The purpose is to determine which gear setting produces the correct amount of seed per unit distance. This helps to achieve optimal planting density based on the field's requirements.

Why is it important to make two or three turns before the seed starts to fall?

-It is important to make two or three turns to ensure that the disk has filled with seeds. The first few turns are inaccurate since the seed distribution hasn’t begun yet, leading to incorrect seed counts.

Why does the wheel's perimeter need to be measured?

-The perimeter of the wheel is measured to calculate how far the machine moves with each wheel rotation. This helps determine the correct amount of seed distribution per unit of distance.

How does the calculation of seed fall relate to planting requirements?

-The seed fall calculation determines how many seeds are dropped over a fixed distance, which is crucial for adjusting the machine to meet the required planting density (e.g., 60,000 plants per hectare).

How does the germination rate affect the seed calculation?

-The germination rate is factored into the calculation by adjusting the required seed count. For example, if the germination rate is 90%, the number of seeds needs to be increased by 10% to ensure the desired plant population.

What is the significance of the spacing between rows?

-The row spacing impacts the planting density and the required number of seeds per linear meter. In this case, a 70 cm spacing between rows directly influences how many seeds are needed per meter.

What adjustment is made when the number of seeds is too high?

-When the seed count is too high, the gear settings are adjusted to slow down the disk’s rotation, reducing the seed fall to match the desired planting density.

How does the gear box affect the machine's seed distribution?

-The gear box allows for easier adjustments to the machine's seed distribution by changing the speed of the disk’s rotation. Different gears can be used to fine-tune the number of seeds dispensed per unit of distance.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Mecanização Agrícola - Parte I

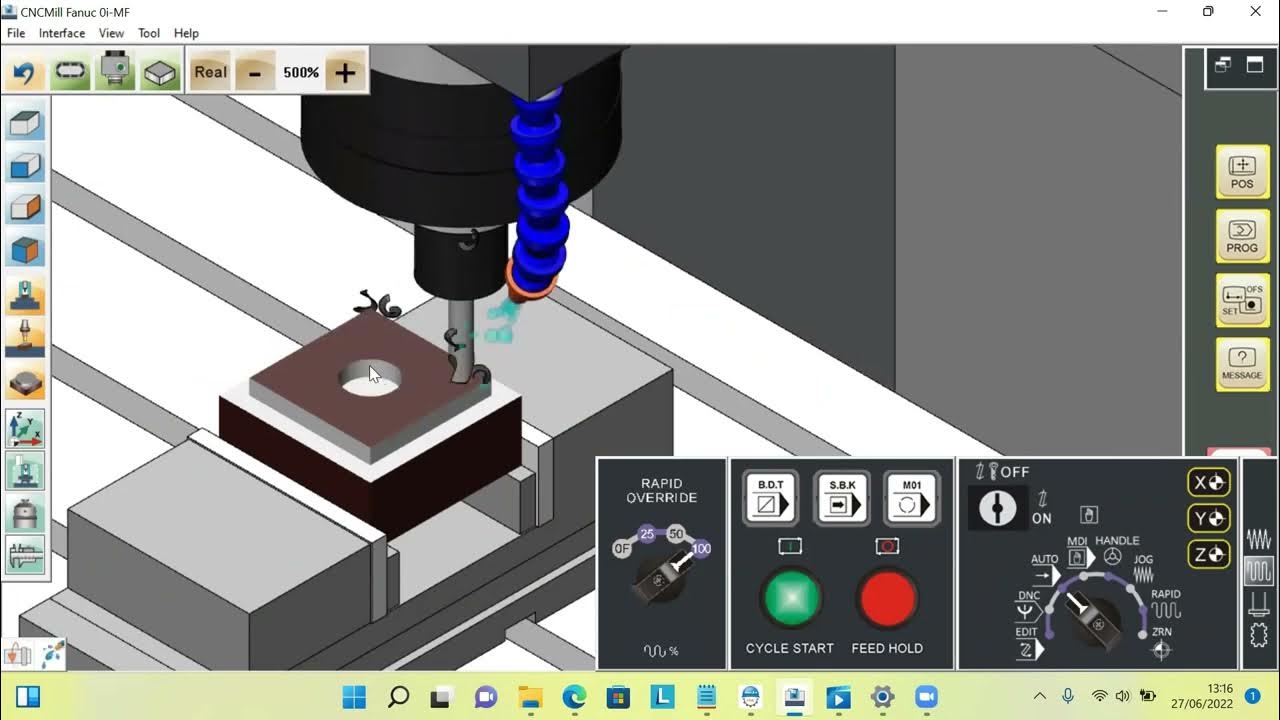

Langkah men-Import File dan memasukkan program dengan Virtual Machine Kontroller Fanuc - Renan

Mecanização Agrícola - Parte IV

ตารางปรับค่า MIG/MAG ใช้ได้กับทุกเครื่อง

Cobas U411 | Urine Analyser | Daily Maintenance | Quality Control | How to Run Control

Gambar Mastercam + Edit + Eksekusi LANGSUNG

5.0 / 5 (0 votes)