PLA vs ABS | What's the Difference for 3D Printing?

Summary

TLDRIn this video, Poppy, a trainer at MakerBot, explains the differences between two common 3D printing filaments: ABS and PLA. PLA is easy to use, less temperature-sensitive, and ideal for basic prints, though not as durable for high-stress applications. ABS, on the other hand, is more challenging to print with but offers greater strength and heat resistance, making it suitable for more demanding parts. The video also covers tips for printing, post-production, and recycling both materials, emphasizing the importance of using the right filament for specific needs.

Takeaways

- 😀 PLA is a user-friendly 3D printing filament, ideal for beginners and general applications.

- 😀 PLA is less sensitive to temperature changes, making it easier to print with and more stable during the process.

- 😀 PLA prints are less durable in harsh conditions and are not suitable for parts exposed to wear and tear or extreme environments.

- 😀 ABS is more challenging to print due to its sensitivity to temperature and cooling rate, requiring a full enclosure and heated build plate.

- 😀 ABS can withstand higher temperatures and is more durable, making it better for applications that experience heat, pressure, or stress.

- 😀 PLA prints tend to have a better surface quality and are more forgiving when printing complex features like overhangs and bridges.

- 😀 ABS prints are more prone to warping and curling but offer more flexibility, bending before breaking compared to PLA.

- 😀 Both PLA and ABS filaments should be stored in dry conditions to avoid moisture absorption, which can affect print quality.

- 😀 Post-production for both PLA and ABS is straightforward: remove the raft, support materials, and optionally smooth or paint the prints.

- 😀 PLA is biodegradable and can break down in landfills, while ABS is not biodegradable and should be recycled through a number 7 recycling program.

Q & A

What are the two main types of 3D printing filament mentioned in the video?

-The two main types of 3D printing filament mentioned are ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid).

Which 3D printer is optimized for printing with ABS filament?

-The MakerBot Replicator 2x experimental 3D printer is optimized for printing with ABS filament.

What makes PLA filament easier to work with compared to ABS?

-PLA filament is less sensitive to temperature changes, which makes it easier to print with, especially in environments without strict temperature control.

What are the drawbacks of using PLA for 3D printing?

-While PLA is easy to work with, it is not suitable for parts exposed to heavy wear or harsh environmental conditions, as it is more brittle and less durable than ABS.

Why does ABS require a heated build plate and enclosure for printing?

-ABS is sensitive to temperature changes and needs to cool slowly during printing. A heated build plate and full enclosure help prevent cracking, warping, and curling during the printing process.

Which filament, PLA or ABS, can withstand higher temperatures and stress?

-ABS can withstand higher temperatures and stress better than PLA, making it more suitable for wear-and-tear applications.

Which filament is more forgiving for printing complex features or vertical overhangs?

-PLA is more forgiving when printing complex features or vertical overhangs. It can print vertical overhangs up to 68 degrees, compared to ABS's 45 degrees.

What is the main challenge when printing with ABS compared to PLA?

-The main challenge when printing with ABS is managing its tendency to warp and curl due to its sensitivity to temperature changes during the printing process.

How can ABS prints be refined after printing?

-ABS prints can be chemically smoothed to hide layer lines, providing a more refined, polished appearance.

What are the environmental considerations for disposing of PLA and ABS prints?

-PLA is biodegradable and can break down in landfills, while ABS does not decompose easily. Both should be disposed of in recycling programs, with ABS being categorized as a number 7 plastic.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

3D printers are worse than I thought. Time to do something about it!

BEST TIPS FOR BETTER PRINTS WITH PETG | Everything you need to succeed with PETG filament

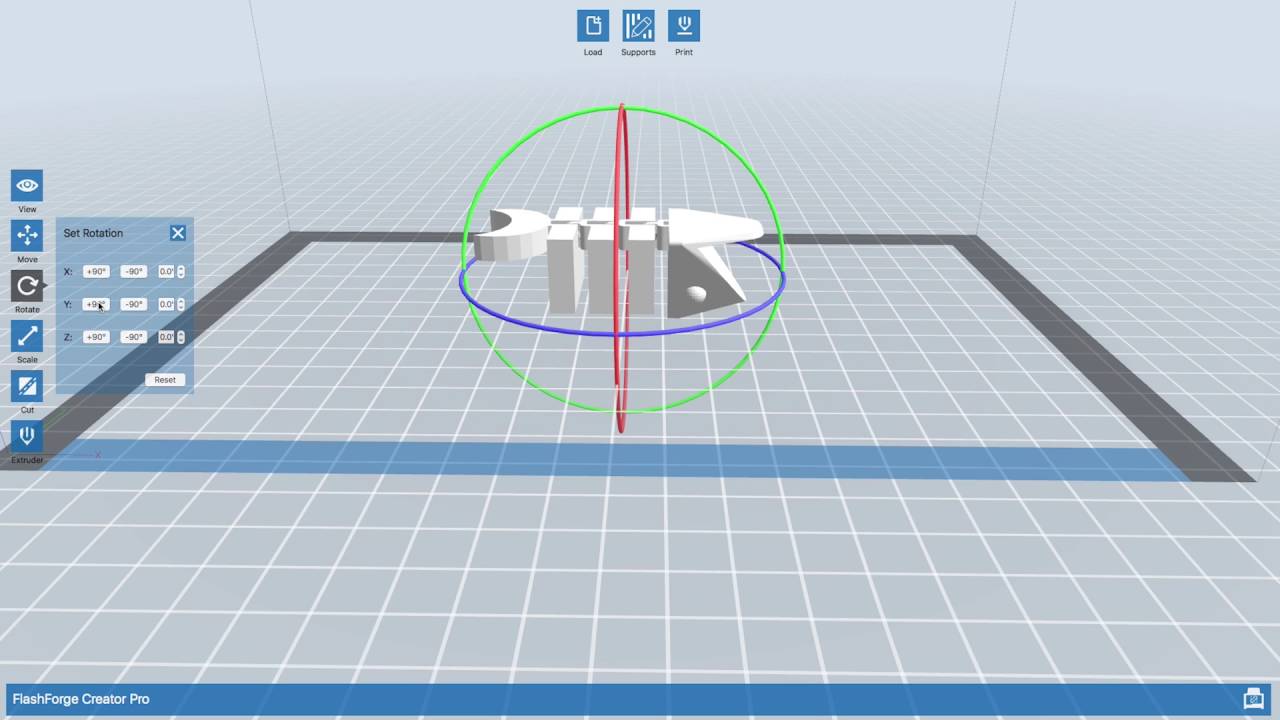

Using the Flashforge Creator Pro 3D Printers - BASICS

3D Printing Materials Explained: Compare FDM, SLA, and SLS

The 5 Filament Types You Need to Know (And What They're Good For)

How to Use a 3D Printer for Complete Beginners

5.0 / 5 (0 votes)