3D Scanning 101 - Why You Should Be Implementing This Technology Right Now

Summary

TLDRThis video provides an in-depth look at 3D scanning technologies, explaining how they work and their various applications. The video highlights both contact and non-contact scanning methods, including time of flight, handheld lasers, structured light, and photogrammetry. It also covers the practical uses of 3D scanning in industries such as manufacturing, medical, entertainment, construction, and cultural heritage preservation. Key factors like accuracy, cost, and the capabilities of different scanners are discussed, helping viewers understand how to choose the right 3D scanning solution for their needs.

Takeaways

- 😀 3D scanning involves analyzing real-world objects or environments to collect data on their shape, color, and texture to create digital 3D models.

- 😀 3D scanners come in a variety of technologies, including both contact and non-contact methods, each suited for different applications.

- 😀 Contact scanning uses systems like CMM (Coordinate Measuring Machines), which involves a probe physically touching the object to gather data with high accuracy.

- 😀 Non-contact scanning methods include laser scanning (e.g., ToF, handheld lasers) and photogrammetry, which are used to scan larger objects and capture fine details.

- 😀 Time-of-flight (ToF) scanning uses laser light to measure distances and is effective for large objects but lacks precision for fine details.

- 😀 Handheld lasers like the EinScan HX can capture fine details (down to 50 microns) and work well with dark or reflective surfaces.

- 😀 Structured light scanning projects patterns and light bars onto an object to gather data, and is commonly used in professional 3D scanners.

- 😀 Photogrammetry involves taking multiple photographs of an object and calculating differences to create a 3D model, though it lacks the measurement accuracy of other methods.

- 😀 3D scanning can be used for reverse engineering, validation of manufactured parts, designing around existing components, and even creating digital inventories for archival purposes.

- 😀 Applications of 3D scanning include industries such as medicine (for prosthetics and custom clothing), construction, law enforcement, cultural heritage preservation, and real estate.

- 😀 The accuracy required from a 3D scanner depends on the application, with high precision (down to microns) required for aerospace and industrial uses, and less precision for general replication or reference purposes.

Q & A

What is 3D scanning?

-3D scanning is the process of analyzing a real-world object or environment to collect data on its shape, and sometimes its appearance like color and texture, which is then used to create digital 3D models.

What are the two main categories of 3D scanning technologies?

-The two main categories of 3D scanning technologies are contact scanning and non-contact scanning.

How does contact scanning work?

-Contact scanning technologies, such as CMM (Coordinate Measuring Machines), use a sensitive probe that physically touches the surface of an object, recording data as it moves along the surface and comparing it to a digital CAD model.

What is time-of-flight technology in 3D scanning?

-Time-of-flight technology uses laser light to probe a subject. The laser’s round-trip speed is measured to calculate the distance to the surface of the object. It is effective for large-scale objects like rooms and buildings but lacks fine detail accuracy.

What is the advantage of handheld lasers in 3D scanning?

-Handheld lasers use triangulation with a laser and multiple sensors, offering higher accuracy (down to 50 microns) and are especially useful for scanning dark and reflective objects.

How does structured light work in 3D scanning?

-Structured light scanning projects a pattern of light (like a QR code) onto the object, and sensors read the deformations of the pattern. Algorithms then process the data to determine the object's shape and size.

What is photogrammetry and its limitation in 3D scanning?

-Photogrammetry involves taking many photographs from different angles around an object and then calculating the differences to form a 3D model. The main limitation is that it doesn't measure while scanning, unlike other methods, although it can be quite accurate depending on the photography style.

Can scanned models be directly imported into CAD software?

-Scanned models cannot be directly imported as parametric designs into CAD software, but tools like Geomagic Wrap and Geomagic Essentials make it easy to convert 3D scans into CAD-friendly formats.

What are some common uses of 3D scanning?

-3D scanning is used in various fields including manufacturing for part validation, custom prosthetics, construction, real estate, cultural heritage preservation, law enforcement, and creating digital inventories of objects like molds or parts.

What factors should you consider before purchasing a 3D scanner?

-Before purchasing a 3D scanner, consider the required accuracy, the intended application (e.g., industrial part validation, reverse engineering), and the budget. Accuracy ranges from microns (for high precision) to millimeters (for general replication).

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

All Types Of Compressor And Working Explained || How Does An Compressor Works?

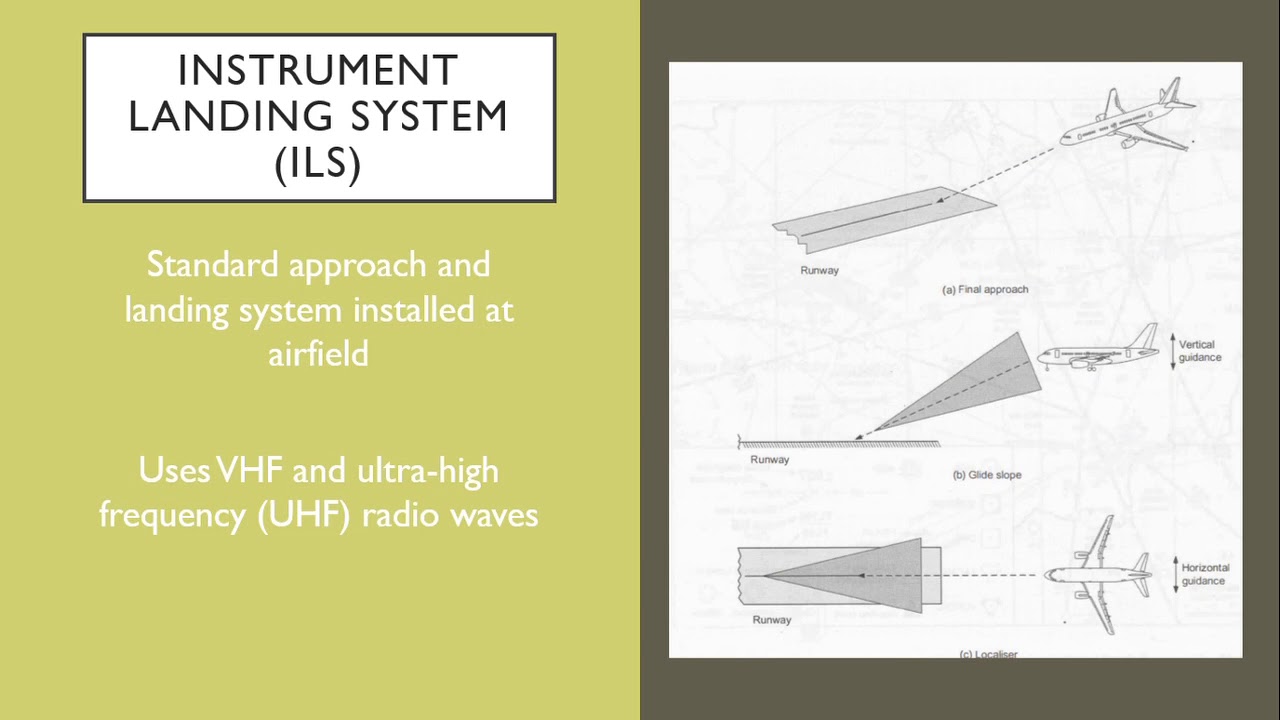

Aircraft Navigation Systems

Introduction to Lexical Analyzer

Vektor Matematika Kelas 10 • Part 1: Definisi Vektor & Cara Menyatakan Vektor

3D Printers - CompTIA A+ 220-1101 - 3.7

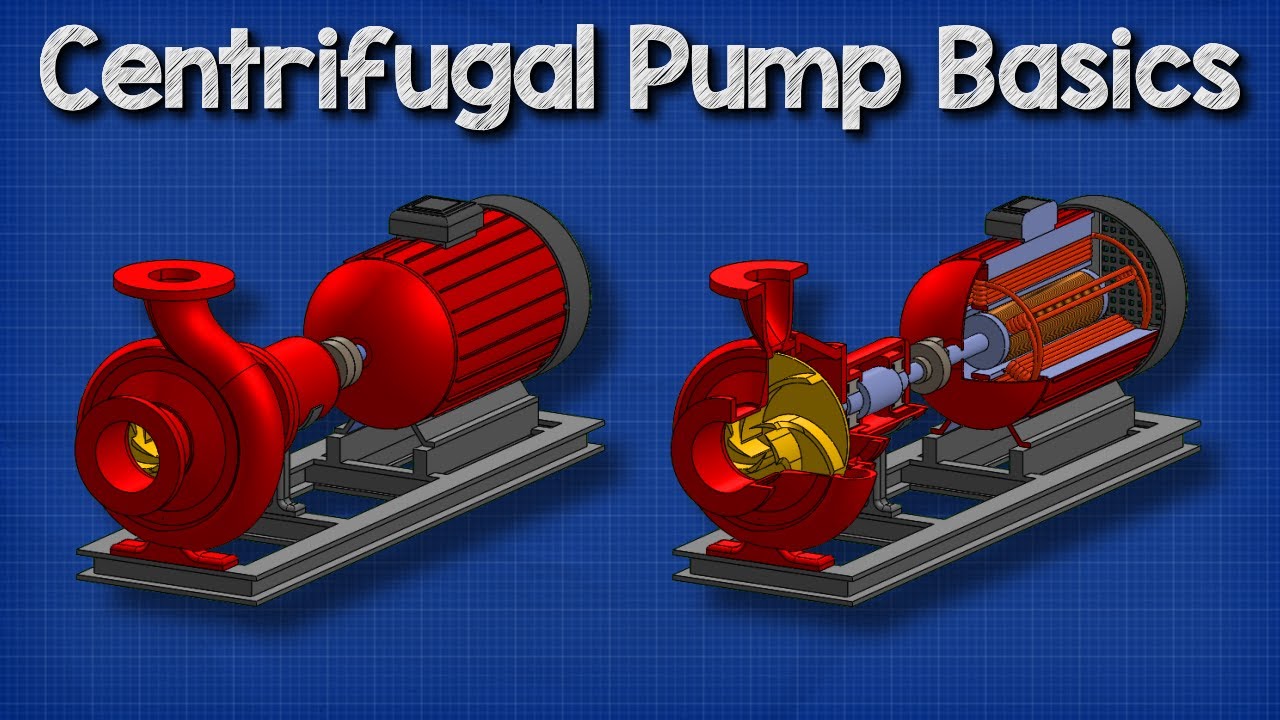

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

5.0 / 5 (0 votes)