Le MOTEUR de l'HYPERCAR est installé ! berceau arrière [Hypercar project #20]

Summary

TLDRThe video follows a man building his own hypercar. He starts by designing the rear chassis and suspension, ensuring it fits with the carbon fiber monocoque and engine. He models custom parts like the rear shock absorbers and swingarms. Significant time is spent problem solving around packaging all the components without interference. He checks for collisions between parts through visual inspection and computer simulation. The end result is a beautifully packaged rear chassis with suspension, ready for the next steps of fabrication and assembly. The passion and attention to detail showcase the man's dream to engineer his own hypercar.

Takeaways

- 🚀 The creator is designing and building their own hypercar, focusing on constructing the rear chassis in this episode.

- 🔨 Initial steps involved researching and studying the rear chassis designs of the world's best cars before developing a custom design.

- 👨🔬 The rear chassis, more complex than the front, holds the suspension, body elements, and notably the mid-rear engine powertrain.

- 📊 Emphasizes the importance of looking at other manufacturers for inspiration and adapting those insights to their specific project.

- 🚗 Highlights the use of a carbon monocoque as part of the chassis technology, common in sports and competition cars, dividing the vehicle into three main sections.

- 🔧 Explains the distinct approach to the rear chassis design for mid-rear engine cars, focusing on its role in holding suspension, bodywork, and engine peripherals.

- 📡 Discusses the challenge of maintaining a balance between engine vibration isolation and chassis rigidity to optimize performance.

- 🛠 Outlines the creative process of designing the rear chassis, including the placement of the engine and transmission for optimal weight distribution.

- 🔬 Describes the detailed CAD design process, including ensuring the suspension geometry is correct and the chassis accommodates all necessary components without interference.

- 🚨 Emphasizes the importance of designing for ease of maintenance and the strategic use of materials and design choices to reduce weight and improve performance.

Q & A

What was the primary focus of the project described in the video?

-The primary focus was to design and manufacture a custom hypercar, with a specific emphasis on creating the rear subframe of the vehicle.

What are the main components included in the front subframe of the hypercar?

-The front subframe includes suspension elements, steering, engine radiator, and carbon blade among other components.

Why is the rear subframe considered more complex than the front?

-The rear subframe is more complex due to its incorporation of the powertrain, including the engine and transmission, as well as various engine peripherals like the intake, exhaust, and cooling systems.

What does the hypercar's chassis consist of?

-The hypercar's chassis consists of a front and rear subframe connected by a carbon monocoque, a design common in high-performance sports and competition vehicles.

How is the powertrain integrated into some high-performance vehicles and prototypes?

-In some high-performance vehicles and prototypes, the powertrain (engine and gearbox) is directly mounted to the carbon cell without a traditional frame, where the engine and gearbox casings provide structural rigidity.

What are the challenges associated with a powertrain that is not isolated by subframe mounts?

-Without isolation by subframe mounts, vibrations from the engine can significantly affect the vehicle's cabin, and road imperfections could potentially damage the engine mechanics.

Why do some manufacturers prefer a powertrain supported by a metallic or carbon fiber subframe?

-Manufacturers prefer a metallic or carbon fiber subframe to support the powertrain because it reduces vibrations transmitted to the cabin and protects the engine from road imperfections, despite being slightly heavier.

What materials are commonly used for the subframe in high-end cars?

-High-end cars commonly use steel, aluminum, or carbon fiber composites for their subframe construction, depending on the vehicle's design and performance requirements.

How does the video describe the process of positioning the powertrain in the hypercar's design?

-The process involves flexibility in positioning the powertrain for optimal mass distribution, while considering constraints like the alignment of the drive shafts and space for components such as the air intake.

What is the significance of the design process involving 'wifi' parts in the context of the video?

-The term 'wifi' parts metaphorically refers to placing and adjusting components virtually in the design software before physical fabrication, to ensure proper fit and function within the hypercar's design.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

The Utah State Tax Commission meets my Koenisgegg Agera.

Est-ce que je suis d'accord avec Audrey ?

Je fais du tuning de Bugatti ! (et je n’ai pas honte)

How I Survived My Ex-Wife's Murder Plot | Minutes With

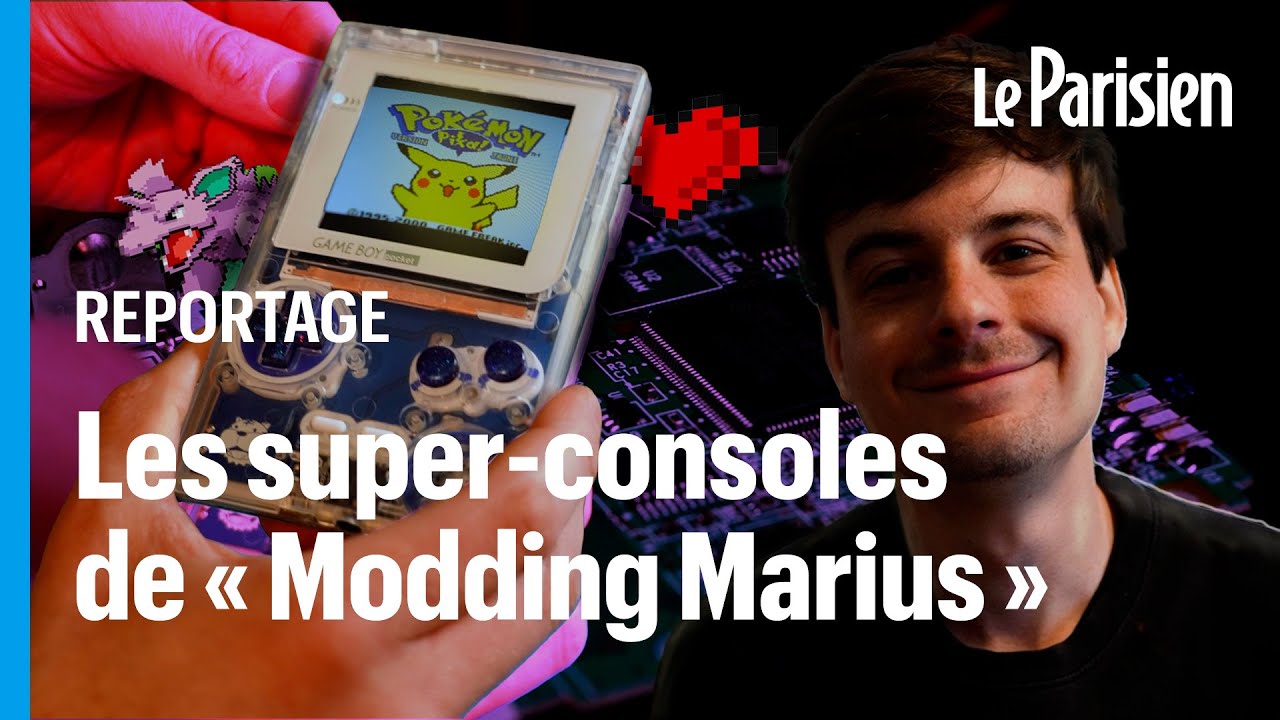

Marius, le « chirurgien » qui redonne vie à vos anciennes Game Boy

The Power of Letting Go | Animated Bedtime Story | Motivational Moral Story in English

5.0 / 5 (0 votes)