PROSES TERJADINYA KOROSI 1.0

Summary

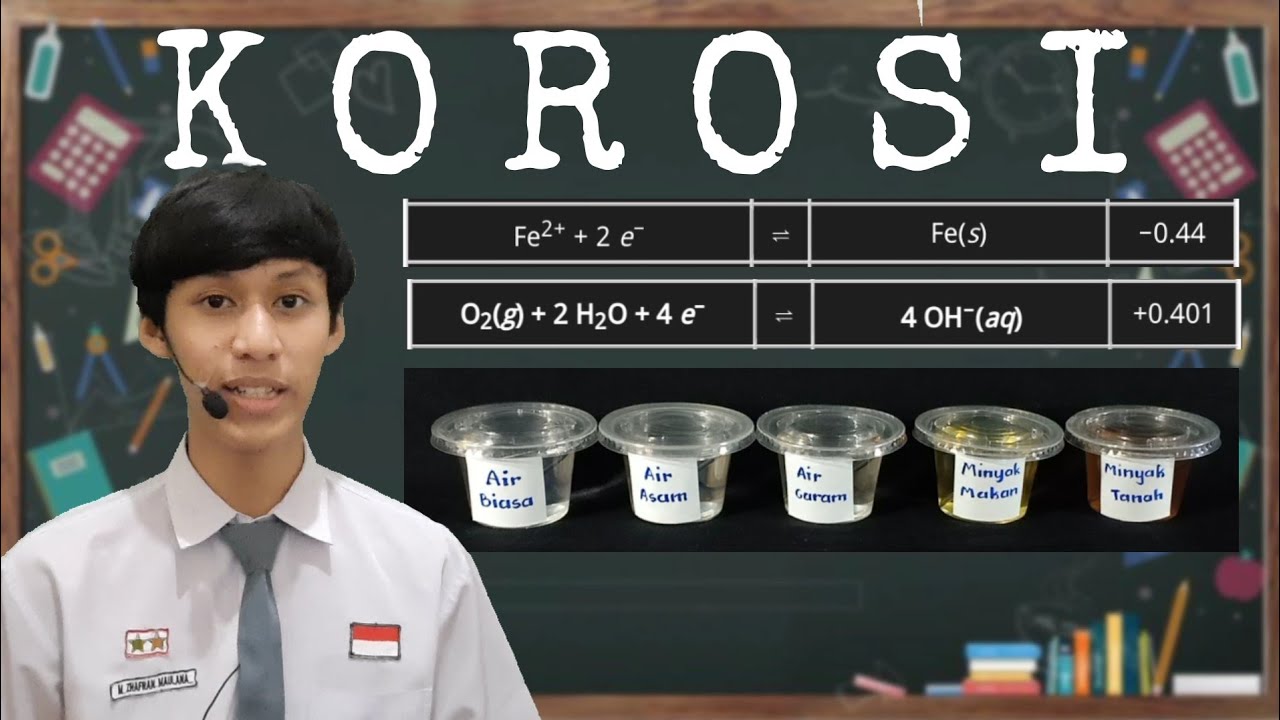

TLDRThe video explains the corrosion process in reinforced concrete, particularly in iron bars, highlighting how bending causes differential potential along the metal. The bent sections become more susceptible to corrosion due to electrochemical reactions, where oxidation of iron at the anode leads to the formation of iron ions and the migration of electrons to the cathode. Oxygen and water facilitate further reactions, perpetuating the corrosion cycle. The script also hints at factors that accelerate corrosion and methods for prevention, aiming to educate viewers about the causes and ongoing nature of metal degradation in construction.

Takeaways

- 😀 Corrosion occurs when steel in reinforced concrete is exposed to moisture and environmental conditions.

- 😀 Steel rebar in reinforced concrete is initially straight but is bent during construction, which can lead to damage in certain areas.

- 😀 The bending of steel creates areas with different electrical potentials, causing some parts to corrode faster than others.

- 😀 The process of corrosion is electrochemical, with parts of the steel becoming anodes and cathodes due to potential differences.

- 😀 At the anode, iron oxidizes, loses electrons, and forms iron ions (Fe²⁺) that dissolve in water.

- 😀 The electrons from the anode move to the cathode, where oxygen reacts with hydrogen ions (H⁺), reducing oxygen and forming water.

- 😀 The presence of water in the environment connects the anode and cathode, enabling the corrosion process to continue.

- 😀 Iron ions (Fe²⁺) can further react with oxygen, forming iron oxide (rust) and accelerating corrosion.

- 😀 The electrochemical reactions at both the anode and cathode lead to the continued deterioration of the steel, weakening the structure.

- 😀 The next phase of the discussion will cover factors that accelerate corrosion and methods to prevent it.

Q & A

What is the main cause of corrosion in reinforced steel (besi beton)?

-Corrosion in reinforced steel occurs due to the formation of a potential difference between the bent and unbent parts of the steel. The bent parts become more susceptible to corrosion because of this potential difference.

Why does bending the steel lead to corrosion in certain areas?

-Bending the steel creates a difference in electrical potential, with the bent areas having a different potential compared to the rest of the steel. This difference accelerates the corrosion process in those areas.

How does moisture contribute to the corrosion of reinforced steel?

-Moisture, particularly water, connects the areas with different electrical potentials on the steel, facilitating the electrochemical reactions that lead to corrosion.

What role do the anode and cathode play in the corrosion process?

-In the electrochemical process of corrosion, the bent part of the steel acts as the anode (where oxidation occurs), releasing iron ions (Fe²⁺), while the unbent part acts as the cathode (where reduction happens), leading to the formation of water and oxygen.

What is the chemical reaction that occurs at the anode during corrosion?

-At the anode, the oxidation reaction of iron occurs, releasing Fe²⁺ ions and electrons. This process causes the steel to deteriorate.

How does oxygen contribute to the corrosion process?

-At the cathode, oxygen molecules combine with the electrons from the anode and hydrogen ions (H⁺) from the water to form water molecules, continuing the cycle of corrosion.

What is the role of Fe²⁺ ions in the corrosion process?

-The Fe²⁺ ions released during oxidation at the anode are further oxidized by oxygen to form iron (III) compounds, contributing to the continued deterioration of the steel.

What factors accelerate the corrosion of reinforced steel?

-Factors that accelerate corrosion include high humidity, the presence of chloride ions (such as from salt), and elevated temperatures, all of which increase the speed of electrochemical reactions.

How can the corrosion of reinforced steel be prevented?

-Corrosion can be prevented by applying protective coatings, using corrosion-resistant materials, and designing structures to minimize exposure to moisture and harsh conditions.

What is the significance of ion hydronium (H⁺) in the corrosion process?

-Ion hydronium (H⁺) plays a critical role in the reduction reaction at the cathode, and its continuous production helps maintain the conditions that sustain the corrosion process.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Korosi | Kimia SMA

Video Pembelajaran Kimia Materi Korosi pada Logam Dilengkapi dengan Animasi

[TEKNOLOGI BAHAN & BETON] PERTEMUAN 5 "PENGUJIAN BETON KERAS NONDESTRUKTIF - PART 2" O/ Dr. JANUARTI

GCSE Chemistry - What is Corrosion and How to Stop it #71

Why Does Metal Rust? - Reactions Q&A

Percobaan Korosi

5.0 / 5 (0 votes)