LASER BEAM MACHINING PROCESS (Animation): Working of LASER beam machining process.

Summary

TLDRThe video explains Laser Beam Machining (LBM), a non-conventional process that uses concentrated laser light to remove material from workpieces. It covers the working principle, construction, and operation of LBM, detailing how lasers are produced and focused to achieve precise machining of various materials. Key applications include engraving, welding, and cutting in industries such as aerospace and medical. While LBM offers advantages like no tool wear and the ability to machine complex shapes, it also has disadvantages, including high energy consumption and low material removal rates.

Takeaways

- 🎯 Laser Beam Machining is a non-conventional process that removes material using concentrated heat from a laser beam.

- 💡 LASER stands for Light Amplification by Stimulated Emission of Radiation, produced when electrons in certain crystals are energized.

- 🔍 Yttrium Aluminium Garnet (YAG) doped with neodymium (Nd:YAG) is a commonly used crystal in solid-state lasers.

- 🔥 The process is ideal for machining brittle materials with low conductivity but can be applied to almost all materials.

- 🔧 The key components of a laser beam machine include a power supply, flash lamp, capacitor, and pumping medium.

- ⚡ When the machine is activated, a high-voltage power supply energizes the pumping medium, resulting in photon emission.

- 🔄 The process amplifies light through stimulated emission, creating a concentrated laser beam focused on the workpiece.

- ✂️ Applications of laser beam machining include engraving, welding, surface treatment, cutting, and drilling across various industries.

- ✅ Advantages of laser beam machining include no tool wear, the ability to work on both conductive and non-conductive materials, and high precision.

- ⚠️ Disadvantages include high energy requirements, low material removal rates, and a short lifespan of the laser lamp.

Q & A

What is Laser Beam Machining?

-Laser Beam Machining is a non-conventional machining process that removes material from the workpiece surface using heat generated by a concentrated laser beam.

What does LASER stand for?

-LASER stands for Light Amplification by Stimulated Emission of Radiation.

How is a laser produced?

-A laser is produced when electrons in atoms of special crystals, commonly garnet crystals, are energized by electric current, leading to the emission of photons, which form a concentrated beam of light.

What types of materials can Laser Beam Machining be used on?

-Laser Beam Machining is best suited for machining brittle materials with low conductivity but can be used on almost any material.

What are the main components of a Laser Beam Machining system?

-The main components include a power supply, flash lamp, capacitor, and a pumping medium (commonly ruby crystal).

What is the role of the flash lamp in the Laser Beam Machining process?

-The flash lamp charges the electrons in the crystal, which is the pumping medium, allowing for the generation of high-energy photons.

What is the working principle of Laser Beam Machining?

-The laser beam strikes the workpiece, transferring heat energy that melts and vaporizes the material, thus machining the surface.

What are some applications of Laser Beam Machining?

-Applications include engraving, welding, surface treatment, cutting, and drilling in industries like shipbuilding, automotive, aerospace, and medical.

What are the advantages of Laser Beam Machining?

-Advantages include no direct contact between tool and workpiece, ability to machine both conductive and non-conductive materials, high machining accuracy, no tool wear, ability to create complex shapes, and excellent surface finish.

What are the disadvantages of Laser Beam Machining?

-Disadvantages include high energy requirements, low material removal rates, and a short lifespan of the lamp used in the process.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

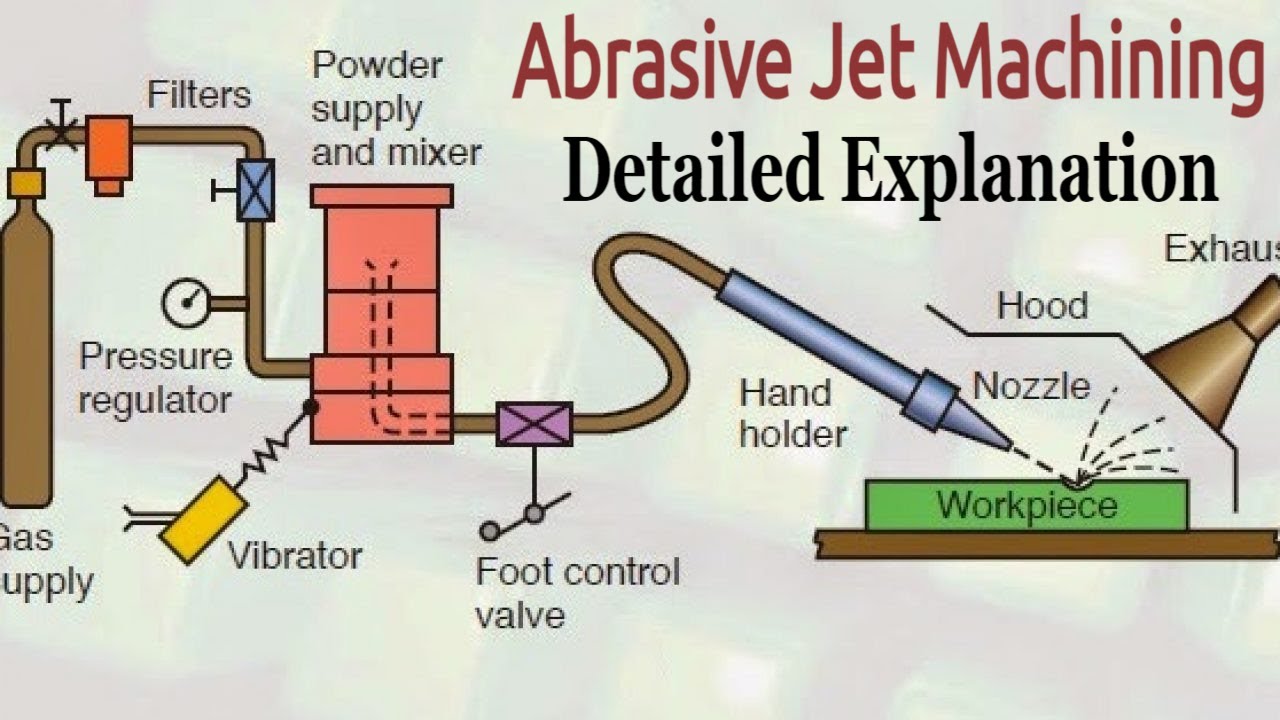

How an Abrasive Jet Machining Works?

Class 7| Scattering Of Light | Science | English Medium | Maharashtra Board | Home Revise

Laser Cutter Machines - How its Made

Percobaan Laser | Praktikum Fisika Dasar 2 | UPT Laboratorium Terpadu UHO

How lasers work (in theory)

How lasers work - a thorough explanation

5.0 / 5 (0 votes)