Toyota 2JZ Engine Build - Full Start to Finish

Summary

TLDRIn this video, Stephan Papadakis from Papadakis Racing walks viewers through the meticulous assembly of a legendary 2JZ engine. The script details the process of preparing the engine block, measuring pistons, checking clearances, and installing components with precision. It also covers painting the block, assembling the pistons and rods, and installing the crankshaft with care. The video is a comprehensive guide for those interested in engine building, showcasing the importance of attention to detail and the correct torque specifications for each part.

Takeaways

- 🔧 The script describes an engine assembly process for a 2JZ engine at Papadakis racing.

- 🏗️ The engine block has been modified with a bore size of 86.25mm and has been decked and hot-tanked for cleaning.

- 📏活塞测量是重要的步骤,以确保活塞和缸壁之间有正确的间隙。

- 🛠️活塞销是自由浮动的,可以在活塞和连杆上旋转,有助于减少磨损。

- 🔩活塞和连杆的组装需要使用组装润滑剂,并确保活塞环间隙正确。

- 🎨发动机组装过程中包括对发动机块进行涂漆,以防止生锈并提供保护。

- 🔄活塞环的安装需要精确的间隙调整,以确保正确的密封和发动机性能。

- ⚙️曲轴和轴承的安装需要精确的扭矩,以确保发动机的稳定性和耐用性。

- 🚫在安装气缸头之前,需要特别注意不要在安装了头螺栓的情况下将垫圈放在头上。

- ⚙️气缸头螺栓需要按照特定的扭矩规格进行拧紧,以确保气缸头的正确密封。

- 📈该脚本还提到了对气缸头进行端口加工以改善气流,以及使用CNC机器进行阀门切割以提高精度。

Q & A

What is the purpose of the project described in the script?

-The purpose of the project is to assemble a legendary hood with a 2JZ engine for a car at Papadakis racing shop.

What modifications have been made to the engine block?

-The engine block has been bored out to 86.25 millimeters, decked (resurfaced the top), and hot tanked (cleaned the outside).

Why is the block being painted after the initial assembly?

-The block is being painted to prevent rust after the hot tanking process removed the original paint.

How are the pistons being measured in the script?

-The pistons are being measured to ensure they have the proper size and wall clearance in relation to the cylinder bores.

What is the function of the free-floating pins mentioned in the script?

-Free-floating pins allow the connecting pin to rotate on both the piston and the connecting rod, which helps reduce wear.

Why are the pistons coated on the top and sides?

-The coating on the top helps with temperature control, while the coating on the sides helps reduce cylinder wear.

What is the purpose of the ring gap adjustments described in the script?

-The ring gaps are adjusted to ensure a very specific gap between the rings, which is crucial for proper sealing and engine performance.

Why are the thrust bearings important when installing the crankshaft?

-Thrust bearings are important because they handle the force when the clutch is engaged, preventing damage to the crankshaft.

What is the significance of the oil squirters installed in the engine?

-Oil squirters help cool the pistons and lubricate the piston pin and cylinder walls, which is essential for engine longevity.

How is the cylinder head prepared in this script?

-The cylinder head is hot tanked, ported (pocket port), and resurfaced to ensure optimal airflow and readiness for installation.

What is the role of the valve spring compressor used in the script?

-The valve spring compressor is used to compress the valve spring assembly, allowing for the installation of the keepers and valve spring retainer.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

How to Check Crankshaft End Play or Thrust Using a Magnetic Deck Bridge: Engine Building 101

Ukuran torsi baud metal duduk dan jalan buat mesin mobil menggunakan kunci momen#bayuputramotor

Pantas Lamborghini Huracan Evo Mahal,! Ternyata Seperti ini Proses Pembuatannya

MYSTERY 2JZ FINALLY HITS THE DYNO!

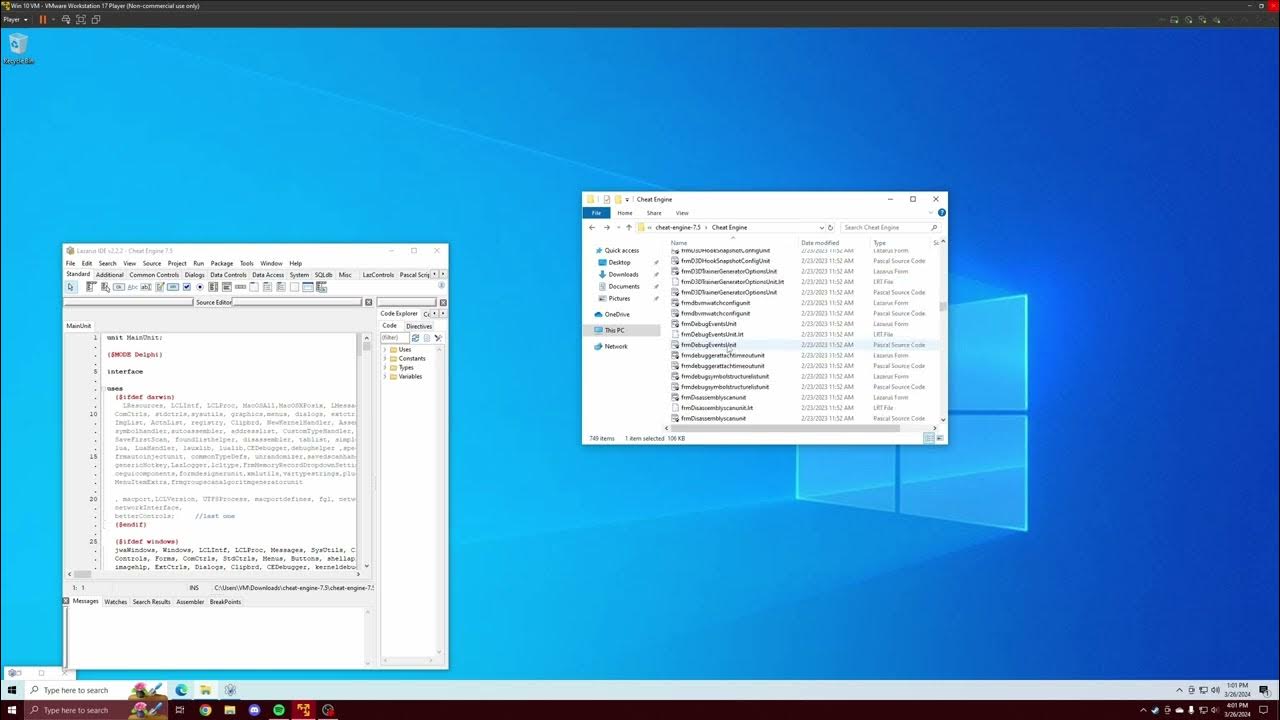

Cheat Engine Built From Source Tutorial | Driver | DBVM | VEH Debugger | Renaming | Error Correction

How MotorCycles Are REALLY Made

5.0 / 5 (0 votes)