Inductive Sensors for Robotics

Summary

TLDRInductive sensors are crucial for robotics, offering touch and proximity detection. They are reliable, robust, and cost-effective, making them ideal for various applications from assembly lines to autonomous vehicles. These sensors work on the principle of electromagnetic induction, detecting metallic objects without contact. They come in shielded and unshielded varieties, each suited for different environments and applications, ensuring precise operation and interaction in robotics.

Takeaways

- 🤖 Inductive sensors are crucial for robots to perceive and interact with their environment.

- 🛠️ These sensors provide a sense of touch or proximity detection, enhancing robotic precision and efficiency.

- 🧩 Known for their reliability, robustness, and cost-effectiveness, inductive sensors are suitable for a broad range of applications.

- 🏭 They are vital in industrial settings like assembly lines for accurate component detection and positioning.

- 🚗 Inductive sensors also play a role in autonomous vehicles for obstacle detection and maintaining safe distances.

- 🏥 They are used in medical robotics for precise instrument positioning during surgical procedures.

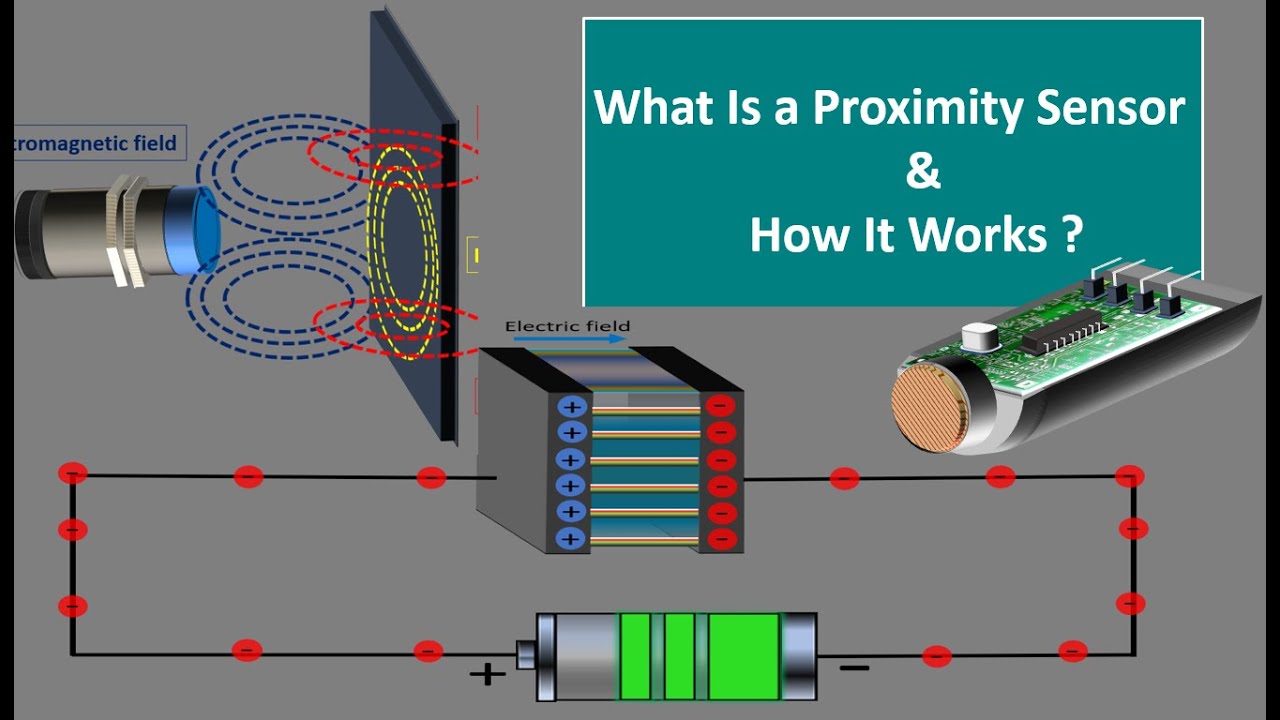

- 🔍 The core principle of inductive sensors is electromagnetic induction, discovered by Michael Faraday.

- 🧲 They operate by generating an oscillating magnetic field that detects metallic objects without physical contact.

- 🛡️ Shielded sensors concentrate the magnetic field for precise detection and are less susceptible to interference.

- 🌐 Unshielded sensors have a wider sensing range but are more prone to false readings due to their diffused field.

- 🔧 The choice between shielded and unshielded sensors depends on the specific application requirements and environmental factors.

Q & A

What role do sensors play in robotics?

-Sensors in robotics play a pivotal role in enabling robots to perceive and interact with their surroundings, providing them with a sense of touch or proximity detection.

Why are inductive sensors considered indispensable in robotics?

-Inductive sensors are considered indispensable due to their reliability, robustness, and cost-effectiveness, making them ideal for a wide range of robotic applications from simple part detection to complex navigation tasks.

How do inductive sensors help in robotic arms on assembly lines?

-Inductive sensors act as the robot's eyes, detecting the presence and position of metal objects, relaying this information to the robot's control system to adjust its movements accordingly.

What is the fundamental principle behind the operation of inductive sensors?

-The fundamental principle behind inductive sensors is electromagnetic induction, discovered by Michael Faraday, which describes how a changing magnetic field can induce an electrical current in a nearby conductor.

How does the presence of a metallic object affect the magnetic field of an inductive sensor?

-When a metallic object enters the oscillating magnetic field of an inductive sensor, it disrupts the field lines, inducing Eddy currents in the object which generate an opposing magnetic field that the sensor detects as a change in inductance.

What is the significance of the non-contact nature of inductive sensors?

-The non-contact nature of inductive sensors eliminates wear and tear, ensuring long sensor lifespan and reliable operation in harsh industrial environments.

What are the differences between shielded and unshielded inductive sensors?

-Shielded sensors have a metallic shield around the coil, concentrating the magnetic field to a smaller, more focused area, while unshielded sensors lack this shield, resulting in a wider, more diffused sensing field.

Why might shielded inductive sensors be preferred in certain applications?

-Shielded inductive sensors are preferred for applications demanding precise detection within a defined area, especially in environments with potential metallic interference, as they reduce sensitivity to metallic objects outside the intended sensing range.

How do unshielded inductive sensors differ in their application suitability?

-Unshielded inductive sensors might be suitable for applications where a wider sensing range is acceptable and the risk of interference is minimal, as they are more prone to detecting unwanted metal objects in close proximity.

What are some applications of inductive sensors beyond industrial settings?

-Inductive sensors are also found in autonomous vehicles for obstacle detection and in medical robots for precise instrument positioning during surgeries.

How do inductive sensors contribute to the future of human-robot interaction?

-As robotics continues to advance, inductive sensors will play an even greater role in shaping the future of human-robot interaction by enabling robots to operate with precision and efficiency in diverse environments.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Belajar Proximity Sensor & Mengkoneksikannya Ke PLC Omron

Exploring the World of Robotics: Types of Sensors

Proximity Sensor working. Inductive proximity sensor, capacitive proximity sensor. proximity switch

Top 10 Digital Inputs in Robotics

Capacitive Sensors in Robotics: A Beginner's Guide

What is Sensors? | Day-To-Day Uses of Sensors | AI Sensors

5.0 / 5 (0 votes)