Bleed Air Systems - Pneumatics - Airframes & Aircraft Systems #38

Summary

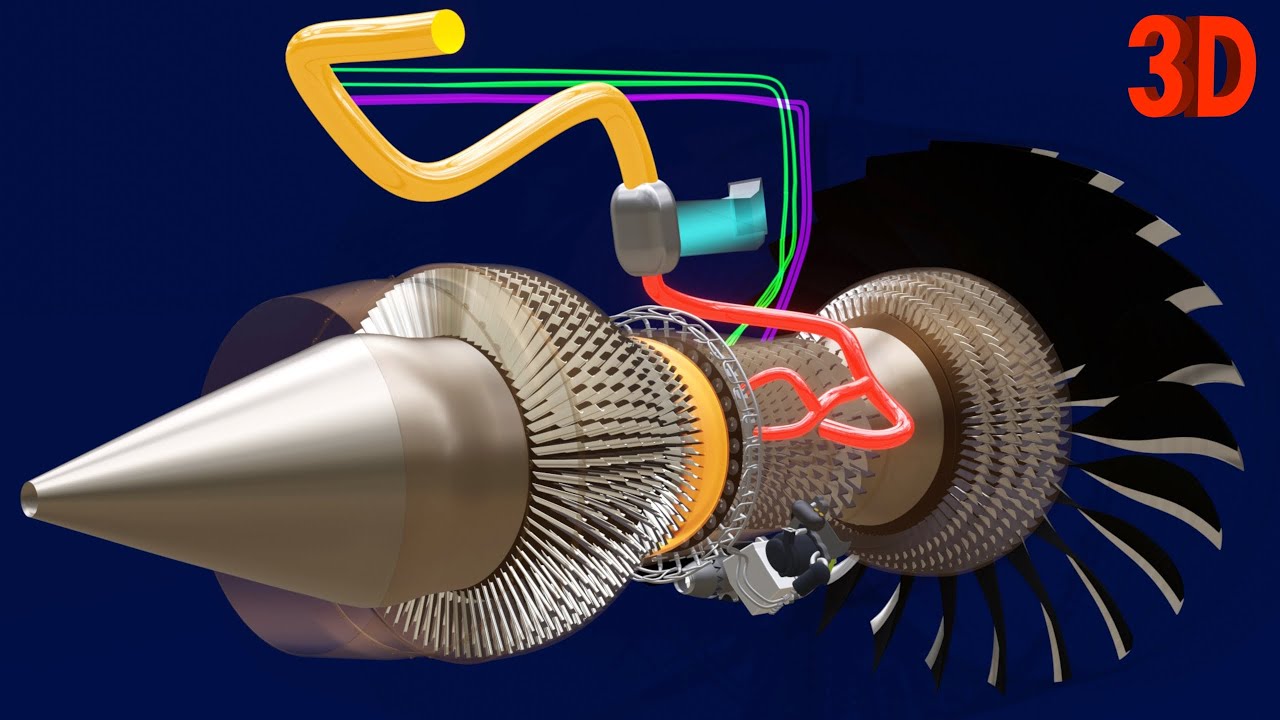

TLDRThis lesson delves into the bleed air systems of modern jet airliners, which are crucial for air conditioning, pressurization, and powering various aircraft components. The system draws air from engine compressors, with backup from the Auxiliary Power Unit (APU) and ground carts. It's designed to handle pressure variations across different engine speeds, using both low-pressure (LP) and high-pressure (HP) air. The air is cooled and regulated to maintain optimal temperature and pressure for various uses. Safety features include duplication of critical components, isolation valves for engine independence, and monitors to prevent over-temperature and over-pressure. The lesson highlights the system's redundancy and safety measures to ensure flight safety.

Takeaways

- 🚀 Modern jet airliners utilize high-volume, low-pressure air systems for various purposes including air conditioning, pressurization, ice protection, and engine starting.

- ✈️ Bleed air, sourced from engine compressors, is the primary supply for these systems, with auxiliary power unit (APU) and ground air supply carts as backups.

- 🔥 The engine bleed air system comprises the engine compressor as the power source, and control devices to regulate temperature and pressure.

- 🔧 The system must maintain a reasonable air supply at low RPM and restrict excessive pressure at high RPM, often by drawing air from two compressor stages.

- 🔄 High-pressure (HP) air is controlled by a pressure-sensitive, pneumatically operated high-pressure shutoff valve (HP SOV) to ensure adequate flow.

- 🌡️ Bleed air from the compressor is too hot for direct use, so it passes through a pre-cooler where engine fan air cools it down to around 175 degrees Celsius.

- 💧 Engine bleed air control valves manage the flow into the pneumatic system, modulating to maintain a maximum duct pressure of approximately 55 psi.

- 🔒 Regulatory requirements mandate that any single component failure in cabin air conditioning or pressurization systems must not compromise safety, leading to system duplications.

- 🛠️ Multi-engine aircraft keep engine supplies separate, with isolation valves that can be opened if one engine supply fails to ensure continued operation.

- ⚠️ The system is equipped with safety measures such as temperature and pressure monitors, with automatic closure of bleed air valves in case of excessive conditions.

- 🔄 In the event of faults, pilots can restore system functionality by opening isolation valves to allow air from one engine to operate the entire system.

Q & A

What is the primary source of air for the high volume low pressure air systems in modern jet airliners?

-The primary source of air for these systems is bleed air from the engine compressors.

What is the role of the Auxiliary Power Unit (APU) in the bleed air system?

-The APU serves as a backup for the bleed air system, providing air when needed.

How does the bleed air system contribute to the aircraft's air conditioning and pressurization?

-The bleed air system is used for air conditioning and pressurization by supplying conditioned air to the cabin.

What are the different uses of bleed air mentioned in the script?

-Bleed air is used for ice protection, engine starting, driving hydraulic pumps, operating air-driven flaps and slats, pressurizing hydraulic reservoirs, potable water tanks, and cargo compartment heating.

How does the bleed air system maintain a reasonable supply of air during varying engine speeds?

-The system takes air from two compressor stages to maintain a reasonable pressure band at all engine speeds.

What is the function of the high-pressure shutoff valve (HP SOV) in the bleed air system?

-The HP SOV is pressure-sensitive and pneumatically operated, opening when there is insufficient air pressure from the LP system to maintain the required flow.

How is the temperature of the bleed air controlled in the system?

-The air from the compressor is passed through a pre-cooler, and a valve modulates the amount of fan air passing through the cooler to control the temperature of the bleed air.

What is the purpose of the engine bleed air control valves?

-These valves control the flow of bleed air into the pneumatic system manifold and are controlled electrically by switches on the flight deck.

Why is it a regulatory requirement to duplicate certain components in aircraft cabin air conditioning or pressurization systems?

-Duplicating components ensures that the failure of any single element does not jeopardize the safety of the aircraft or its occupants.

What happens if there is a failure in the bleed air system that could cause excessive temperature or pressure?

-If the temperature or pressure becomes excessive, the bleed air valve will automatically close, and a warning light in the cockpit will come on.

How can a pilot restore the bleed air system in the event of a fault?

-The pilot can restore the system by opening the isolation valve, allowing air from one engine to operate the entire system.

Outlines

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードMindmap

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードKeywords

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードHighlights

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレードTranscripts

このセクションは有料ユーザー限定です。 アクセスするには、アップグレードをお願いします。

今すぐアップグレード関連動画をさらに表示

Ram Air - Pneumatics - Airframes & Aircraft Systems #37

Air Conditioning Part 2 - Pneumatics - Airframes & Aircraft Systems #40

737NG Bleed Air System explained | Real 737 Pilot

Pressurization - Pneumatics - Airframes & Aircraft Systems #41

How Jet Engine Works | Part 2 : Outputs

Jet Engine Bleed Air - Aircraft Gas Turbine Engines #15

5.0 / 5 (0 votes)