Ford Motor : Supply Chain Strategy & Challenges | Harvard Business | MBA Solved Case Study analysis

Summary

TLDRIn this video, we explore Ford's supply chain challenges and its strategic evaluation to integrate with Dell's computer model. With a complex network of suppliers and intense competition, Ford initiated the Ford 2000 plan to streamline operations. The company considered adopting Dell's virtual integration but faced unique challenges due to the nature of the automotive industry. The script discusses potential solutions, including a hybrid approach and a fully integrated supply chain, emphasizing the importance of strategic IT investments, collaboration, and continuous improvement for a competitive edge.

Takeaways

- 🚘 Ford Motor Company is a major player in the automotive industry with a rich history and significant financial success.

- 💼 Ford's supply chain faced challenges due to its large scale and complex operations, including financial subsidiaries and global competition.

- 📈 The company reported substantial net income and revenue growth, reflecting a strong market position in the 1990s.

- 🤝 Ford traditionally competed with General Motors and Chrysler, but the entry of Japanese automakers increased competition, leading to industry consolidation.

- 🔄 Ford launched the Ford 2000 plan to address supply chain complexities, aiming to reduce order-to-delivery times and streamline processes.

- 🛠️ The Ford Production System (FPS) was introduced to transform the supply chain from push-based to pull-based, enhancing efficiency.

- 🔍 Ford sought to reduce the number of suppliers and develop close relationships with key tier one suppliers to manage the supply chain more effectively.

- 🛒 The Ford Retail Network (FRN) was aimed at reducing competition among dealerships, unifying the customer experience.

- 💻 The digital era brought a decision point for Ford regarding the adoption of Dell's integrated supply chain system, which posed unique challenges due to the nature of the automotive market.

- 🔄 Ford considered a hybrid approach, combining online ordering with physical dealerships, to offer customization and control over the customer service experience.

- 🔎 The company also explored a fully integrated supply chain inspired by Dell, which promised customization, faster order fulfillment, and improved relationships with customers and suppliers.

Q & A

What was the primary challenge Ford faced in its supply chain?

-Ford faced the challenge of managing a complex and expensive supply chain due to its vast number of suppliers and intricate business relationships.

What was the Ford 2000 plan and what was its main objective?

-The Ford 2000 plan was an ambitious restructuring initiative launched in 1995 aimed at reducing order to delivery (OTD) times from over 60 days to just 15 days or less and transforming the supply chain from a push-based model to a pull-based one.

How did Ford attempt to reduce the complexity of its supply chain?

-Ford attempted to reduce supply chain complexity by reducing the number of suppliers, focusing on developing close, long-term relationships with tier one suppliers who managed tier 2 and tier 3 suppliers.

What was the Ford Retail Network (FRN) and its goal?

-The Ford Retail Network (FRN) was an initiative aimed at reducing competition among dealerships in the same vicinity, with the goal of having one unified dealer providing the highest level of customer experience.

What was the pivotal decision Ford's director of supply chain systems had to make?

-The director had to decide whether to adopt Dell's integrated supply chain system or explore alternatives, considering the unique challenges posed by Ford's extensive supplier network and business relationships.

What were the key steps involved in adopting Dell's virtual integration strategy?

-The key steps included establishing a dedicated department for new business processes, investing in high-tech equipment, creating a network of connectivity between suppliers and Ford's master network, and continuous review and improvement of the new model.

Why might adopting Dell's supply chain model not be a perfect fit for Ford?

-Adopting Dell's model might not be a perfect fit for Ford because the automobile market differs from computer manufacturing and distribution, where customers often need to test drive a car before making a purchase.

What were some of the long-term and short-term issues Ford needed to address?

-Long-term issues included managing Ford's extensive database of business partners and suppliers, while short-term issues involved outdated IT infrastructure and lack of direct end-user control due to independent dealerships.

What alternative strategies were proposed for Ford's supply chain?

-Alternative strategies included a hybrid approach combining online and offline operations, and a fully integrated supply chain inspired by Dell's model, which involved sharing information between systems and coordinating the flow of materials in production.

What recommendations were made for Ford to improve its supply chain efficiency and profitability?

-Recommendations included implementing a web-based supply chain system, realigning the purchasing department with product development for collaboration, and outsourcing forecasting to a third-party expert.

How did the script suggest Ford should monitor and control the transition to the new system?

-The script suggested assigning an IT specialist as a liaison, implementing a reliable system to monitor online orders, conducting regular customer satisfaction surveys, and holding performance analysis and executive meetings to track progress.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Dell Supply chain strategy | Direct sales Model | Supply chain Case study | Make to order | SCM

Supply chain management of McDonald's | Lean Principles | Sustainability | Technology Implementation

Introduction to Supply Chain Management Part 1

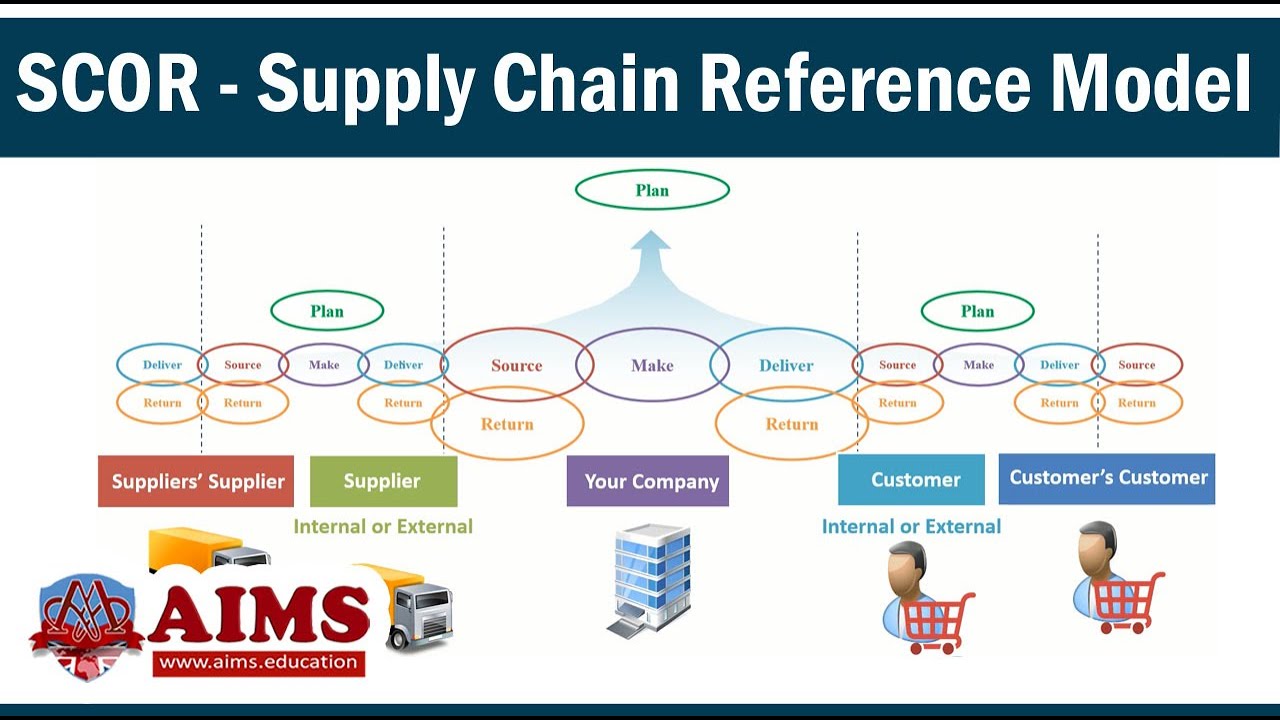

What is SCOR Model Supply Chain? & How Does Supply Chain Operations Reference Model Work? AIMS UK

What is a Supply Chain?

Supply Chain Disruptions: Problems and Solutions

5.0 / 5 (0 votes)