Beginner how to Solder

Summary

TLDRThis beginner-friendly soldering tutorial provides a practical, concise guide to using different types of soldering irons, including electric, butane, and soldering stations. The video explains proper temperature settings for various tasks, emphasizes the importance of using rosin-core solder for electronics, and demonstrates essential techniques like tinning wires, twisting for mechanical strength, and applying solder correctly. It also covers maintaining your soldering iron tip and handling larger components. Viewers will gain a clear understanding of how to create strong, reliable solder connections while avoiding common mistakes, making it an ideal resource for newcomers and hobbyists.

Takeaways

- 🛠️ Beginners can start soldering with simple irons like a RadioShack 15–30 watt model or a butane soldering iron for portable work.

- 🔥 Soldering stations offer higher wattage (up to 100W), and typical temperatures range from 315–370°C (600–700°F) depending on the task.

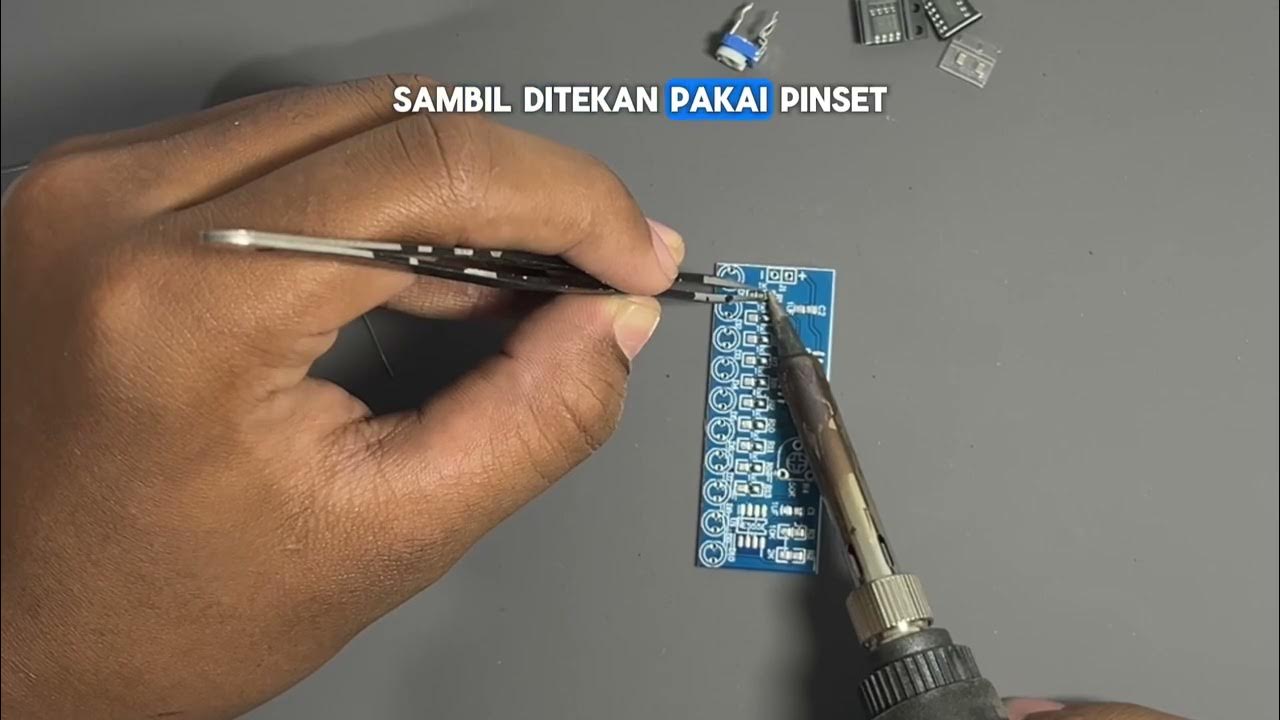

- 🎯 Surface mount components require sharper tips and lower temperatures (around 315°C / 600°F) to prevent damage.

- 💧 Always keep your soldering iron tip clean using a damp sponge or water to maintain good heat transfer.

- 🔧 Use rosin core solder for electronics; acid core solder will damage components.

- ♻️ Tin the soldering iron tip with fresh solder before starting to ensure good adhesion to metals.

- ⚡ When soldering wires, heat the metal first and then apply solder to the hot metal, not the iron itself, for better bonding.

- -

- 🤝 Twisting wires together before soldering creates a stronger mechanical and electrical connection.

- 🧰 Helping hands or clamps make holding components or wires easier during soldering.

- 📏 Heat-sensitive insulation requires quick soldering to prevent melting the wire coating.

- 🔄 Solder will stick to soldered metal, so properly tinned wires can be reheated and joined even without twisting.

- 🔧 Bigger components dissipate more heat, so use a wider tip or higher temperature for efficient soldering.

- ♨️ When repairing old joints, apply fresh solder first to make the old solder easier to work with.

- 💡 Regular maintenance of the soldering iron tip ensures consistent performance and quality connections.

Q & A

What types of soldering irons are mentioned in the video?

-The video mentions a basic RadioShack 15 or 30 watt soldering iron, a butane soldering iron for portability, and a more advanced 100-watt soldering station.

What temperature range is recommended for most soldering applications?

-Most soldering applications are recommended to be between 315°C and 370°C (600°F to 700°F), depending on the type of work.

Why is it important to keep the soldering iron tip clean?

-Keeping the tip clean ensures proper heat transfer and prevents poor solder adhesion. The tip can be cleaned with a wet sponge or by shaking off excess solder.

What is the difference between rosin core and acid core solder?

-Rosin core solder is used for electronics because it contains flux that helps solder stick to metal. Acid core solder is not suitable for electronics as it can damage components.

Why should you apply solder to the metal and not directly to the soldering iron tip?

-Applying solder directly to the metal ensures proper heat transfer and allows the flux to work correctly, which helps the solder adhere to the metal.

What is the recommended method for soldering two wires together?

-Twist the wires together first, then heat them and apply solder. This ensures a stronger mechanical and electrical connection. Tools like a helping hand can make the process easier.

How does tinning wires help in soldering?

-Tinning wires involves coating them with solder first. This helps solder stick easily to the wires and allows for better reflow when connecting wires or components.

What precautions should be taken when soldering surface-mount components?

-Surface-mount components require a sharp tip and lower temperature (around 315°C or 600°F) because excessive heat can damage the components. Work quickly to prevent overheating.

Why is adding fresh solder to an old joint important before reworking it?

-Adding fresh solder to an old joint helps the flux work more effectively, making the solder easier to melt and reflow, which improves the quality of the connection.

What are some options for insulating soldered wire connections?

-You can use electrical tape for a quick and cheap solution, or heat shrink tubing for a more secure and professional insulation.

How does component size affect soldering technique?

-Larger components like big resistors or capacitors dissipate more heat, so using a fatter tip or higher temperature (closer to 371°C or 700°F) helps achieve proper solder flow.

Why might someone see solder stick to solder instead of metal, and is this acceptable?

-If wires are well-tinned, solder can stick to solder without twisting the wires together. While mechanically not as strong as twisted connections, it still forms a good electrical connection.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Soldering Tutorial for Beginners: Five Easy Steps

Soldering Crash Course: Basic Techniques, Tips and Advice!

Learn Soldering - Beginner tips and advice!

DIY101: HOW TO USE A SOLDERING IRON

Learn How to Solder - a How to Guide with Equipment Recommendations - Repair Your Game Consoles!

Cara Menyolder SMD Menggunakan Solder Biasa Tanpa Mesin

5.0 / 5 (0 votes)