Centrifugal compressor working Principal with animation

Summary

TLDRThis video explains the operation of centrifugal compressors used in large capacity cooling systems. It outlines the key components—impeller, diffuser, and volute casing—and describes how refrigerant vapor is compressed through centrifugal force and velocity changes. The impeller moves vapor from the center to the outer edge, increasing speed but not pressure. The diffuser slows the vapor, converting velocity pressure to static pressure. The volute casing collects the high-pressure vapor, and inlet guide vanes regulate capacity. Additionally, speed control can adjust compressor capacity, making these compressors efficient for large-scale refrigeration systems.

Takeaways

- 😀 A centrifugal compressor uses non-positive displacement vapor compression to handle large amounts of refrigerant in cooling systems.

- 😀 The centrifugal compressor has three main components: an impeller, a diffuser, and a volute casing.

- 😀 Large capacity centrifugal compressors can feature multiple impellers or stages within a single casing.

- 😀 Hermetic electric motors typically drive centrifugal compressors, but they can also be powered by steam turbines, gas turbines, or engines.

- 😀 The impeller is a rotating disc with curved blades that moves refrigerant vapor from the suction opening to the outer edge using centrifugal force.

- 😀 The impeller's rotational energy transfers to the vapor, increasing its velocity but not static pressure.

- 😀 The diffuser slows down the vapor, converting its velocity pressure into static pressure to achieve the desired pressure increase.

- 😀 Some centrifugal compressors have diffusers with veins or pipes that change the flow direction and further reduce vapor speed.

- 😀 The volute casing collects the high-pressure, low-velocity vapor from the diffuser and directs it to the compressor’s discharge connection.

- 😀 Inlet guide vanes control the compressor’s capacity, adjusting refrigerant flow and ultimately controlling the cooling capacity of the system.

Q & A

What is the primary function of a centrifugal compressor?

-The primary function of a centrifugal compressor is to compress large amounts of refrigerant vapor using non-positive displacement vapor compression for cooling systems, typically in large capacity applications.

What are the three basic components of a centrifugal compressor?

-The three basic components of a centrifugal compressor are the impeller, the diffuser, and the volute casing.

How does the impeller in a centrifugal compressor work?

-The impeller is a rotating circular disc with curved blades driven by an electric motor. It moves refrigerant vapor from the suction opening at the center to the outer edge using centrifugal force, increasing the velocity of the vapor.

Why does the high velocity of the vapor leaving the impeller not lead to high static pressure?

-High velocity does not relate to high static pressure because the vapor's velocity must be slowed down to convert its velocity pressure into static pressure, which is achieved by the diffuser.

What role does the diffuser play in a centrifugal compressor?

-The diffuser slows down the high-velocity vapor as it moves radially outward, which increases the static pressure of the refrigerant vapor.

Can you explain how the volute casing functions in a centrifugal compressor?

-The volute casing collects the slow-moving, high-pressure vapor from the diffuser and directs it to the discharge connection of the compressor.

How do inlet guide vanes control the capacity of a centrifugal compressor?

-Inlet guide vanes control the capacity by adjusting the amount of refrigerant flow into the compressor. When fully open, the compressor operates at full capacity; as they close, the refrigerant flow decreases, reducing the compressor's capacity.

What is an alternative method of controlling the capacity of a centrifugal compressor?

-In addition to adjusting the inlet guide vanes, the capacity of a centrifugal compressor can also be controlled by changing its rotating speed.

What type of electric motors are commonly used to drive centrifugal compressors?

-Centrifugal compressors are usually driven by hermetic electric motors, though open-drive models are available for use with steam turbines, gas turbines, or engine drives.

How does the design of centrifugal compressors support large capacity cooling systems?

-Centrifugal compressors are designed with multiple stages or impellers to handle large volumes of refrigerant, allowing them to compress large amounts of refrigerant vapor effectively in high-capacity cooling systems.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Industrial Air Compressors Introduction and Working

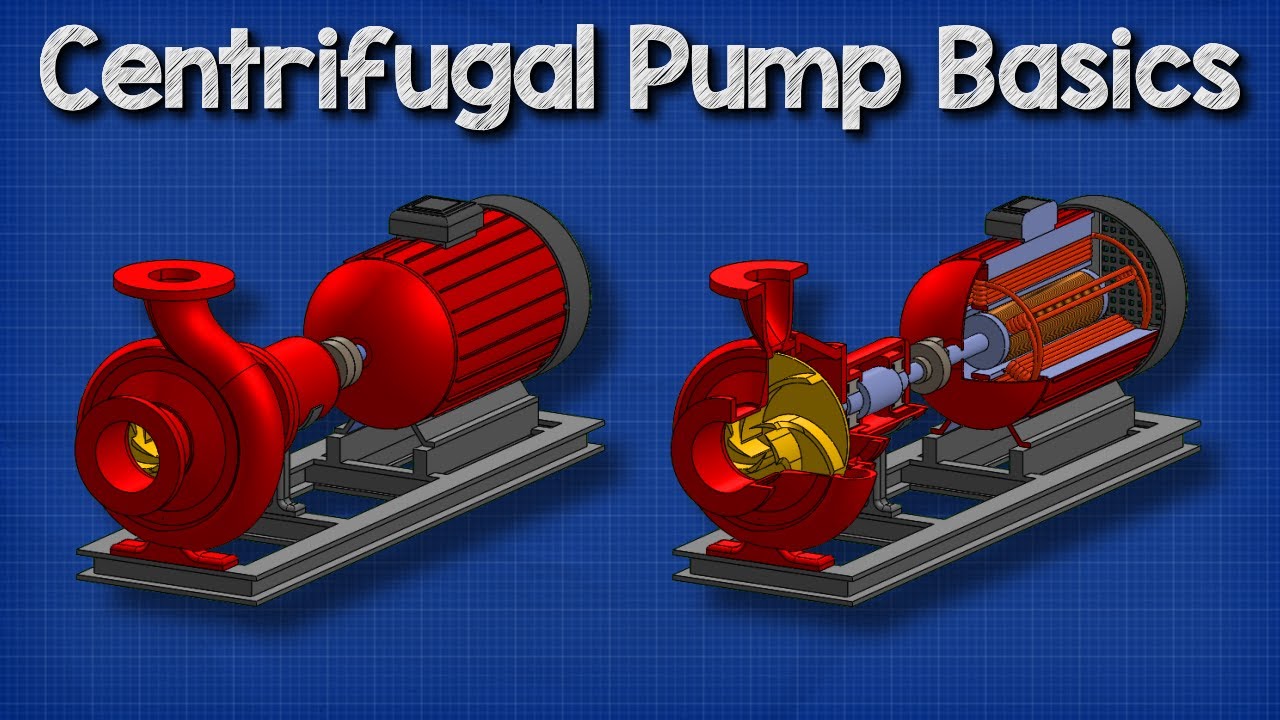

Centrifugal Pump Basics - How centrifugal pumps work working principle hvacr

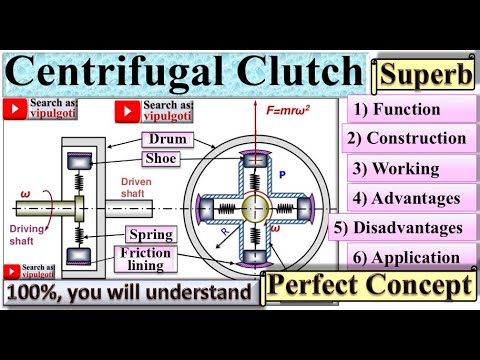

Centrifugal clutch, #Clutch, Function and working of Clutch, #Centrifugal #GTU #BME

Basic Principles and Energy Transfer in Centrifugal Compressor Part - I

Surge l Surge In centrifugal Compressor l

How Engine Cooling System Works ? Cooling System Explained |Air Cooled | Oil Cooled | Liquid Cooled

5.0 / 5 (0 votes)