Process of making ultra-high-strength concrete pile. Korean No.1 PHC pile factory

Summary

TLDRThe video script outlines the comprehensive production process at Samil C&S in Gyeongsang-do, Korea, detailing various stages involved in manufacturing products. These include the cutting and processing of PC steel bars, assembling hardware and jigs, moving items, pouring concrete, mold assembly, and the application of strong tension. The script also covers critical steps such as centrifugal forming, steam curing, mold dismantling, product demolding, and secondary high-temperature curing. Each step highlights the precision and attention to detail involved in producing high-quality products.

Takeaways

- 😀 Cutting PC steel bars is the initial step, where they are processed for further use in construction.

- 😀 The process of making a piece involves the creation of individual components from raw materials.

- 😀 Assembling hardware and jigs ensures proper alignment and structure during the manufacturing process.

- 😀 Moving items is essential to transport materials and components across different stages of production.

- 😀 Pouring concrete into molds is a critical step in forming the base of the product being created.

- 😀 Mold assembly involves preparing and placing the necessary components to shape the concrete.

- 😀 Strong tension is applied to enhance the strength of the concrete and steel through techniques like prestressing.

- 😀 The centrifugal forming process uses rotational forces to shape the concrete or steel in the mold.

- 😀 Primary steam curing accelerates the concrete's curing process through controlled exposure to steam.

- 😀 After curing, the molds are dismantled to release the concrete product.

- 😀 The product is demolded, revealing the finished concrete structure for further steps in production.

- 😀 Disassembling the jig is necessary once the product is formed to prepare for the next stage.

- 😀 Product marking is done for identification and quality control purposes.

- 😀 Secondary high-temperature and high-pressure curing further strengthens the concrete product, ensuring durability.

Q & A

What is the location of 'Samil C&S'?

-'Samil C&S' is located in Gyeongsang-do, Korea.

What is the first process described in the script?

-The first process described is the cutting of PC steel bars and processing hating.

What follows the cutting of PC steel bars in the production process?

-After cutting the PC steel bars, the next process is making a piece.

What is involved in the assembly process?

-The assembly process involves assembling hardware and jigs.

How are items moved during production?

-The process of moving items is part of the overall production process, ensuring that the materials and components are transported to the correct stages.

What is the next major step after moving the items?

-The next major step after moving items is pouring concrete.

What happens in the mold assembly process?

-In the mold assembly process, the necessary molds are prepared and assembled for the upcoming stages of production.

What does 'strong tension' refer to in the production process?

-Strong tension refers to the application of significant force to the materials to ensure they are properly aligned or stretched during the production process.

What is the centrifugal forming process?

-The centrifugal forming process involves rotating molds at high speeds to shape materials evenly and efficiently.

What happens after primary steam curing in the process?

-After the primary steam curing process, the molds are dismantled in the mold dismantling process.

What does the demolding process involve?

-The demolding process involves removing the product from the mold once it has hardened or cured.

What happens during the disassembly of the jig?

-The disassembly of the jig involves taking apart the jig used to hold the components during production, once the product is complete.

What is the purpose of product marking?

-Product marking involves labeling or marking the products with necessary identification or quality assurance details.

What is the final curing process described in the script?

-The final curing process is the secondary high-temperature and high-pressure curing, which ensures the product achieves the desired strength and durability.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Interesting Slide Sandal Mass Production Process. EVA Slippers Manufacturing Factory

90 Million Padlocks Annually! Unveiling the Mass Production Secrets in The Chinese Factory

Complete Process of Textile Manufacturing Fiber to Complete Garments

How the Tesla Model S is Made | Tesla Motors Part 1 (WIRED)

Prototype | Tipe-Tipe Prototype | Prototype Evolusioner | Prototype Equirement

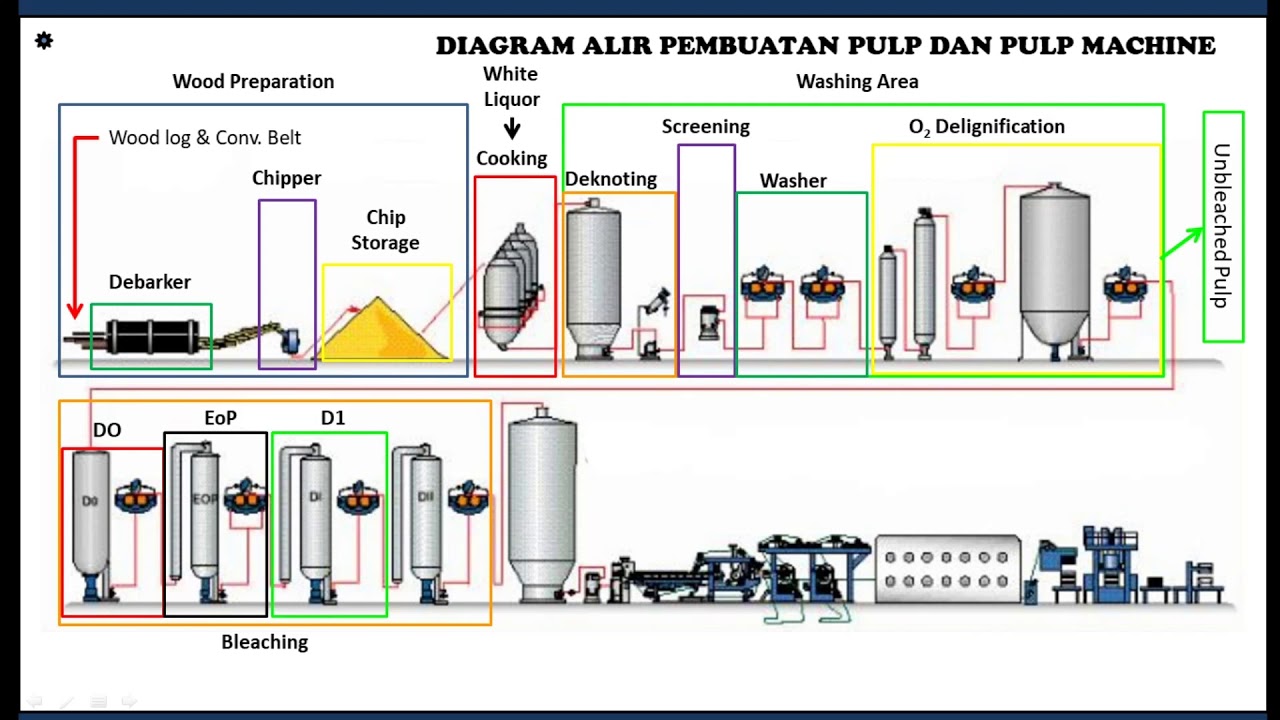

Kimia Industri - Pembuatan Pulp dan Kertas (Diagram Alir proses) (Bag. 2 - Akhir)

5.0 / 5 (0 votes)