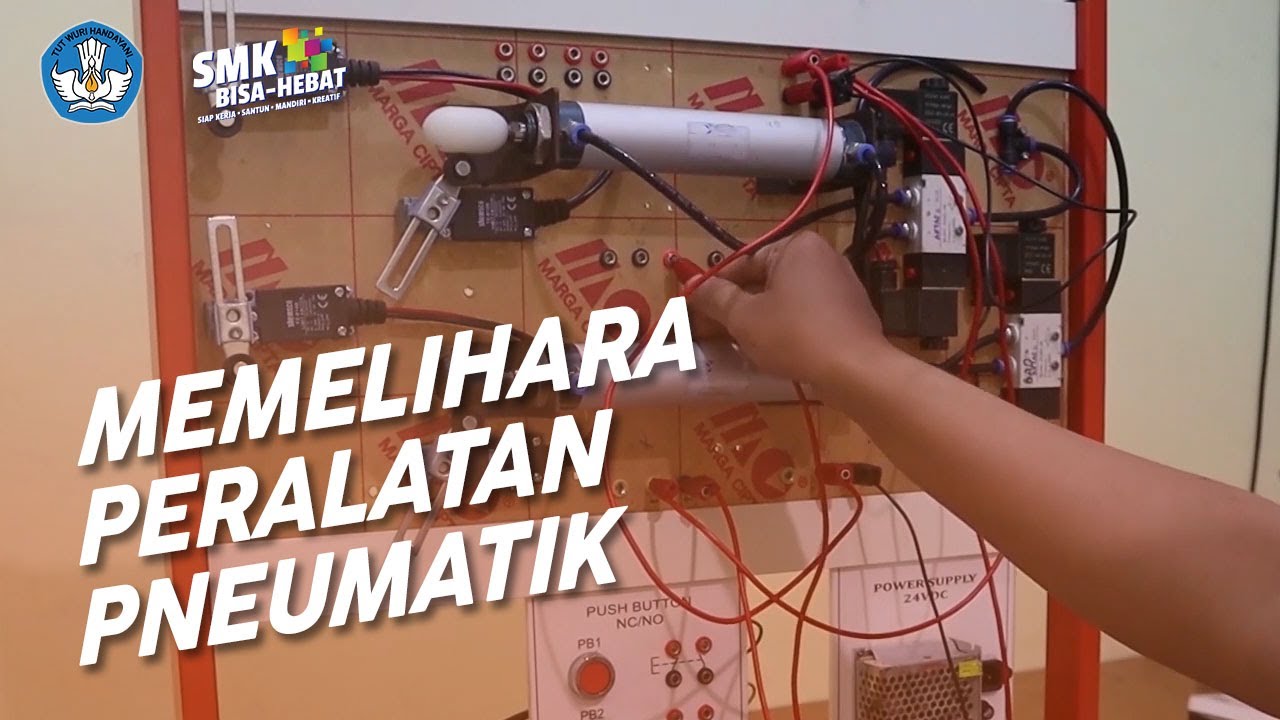

Tutorial Elektopneumatik : pengenalan komponen dan cara instalasi sistem elektro-pneumatik

Summary

TLDRThis video provides a comprehensive introduction to electro-pneumatic systems, covering key components such as compressors, valves, and cylinders. It explains how these components work together to control air pressure, movement, and system functionality. The system's electrical setup, including relays, pushbuttons, and wiring, is also covered in detail. Additionally, the video walks through the installation process and testing procedures to ensure proper operation. Overall, it offers a clear understanding of how pneumatic and electrical components interact in industrial applications to create an efficient and automated system.

Takeaways

- 😀 Compressors are essential for compressing air in pneumatic systems and consist of several components such as an electric motor, reservoir, automatic system, and manometer.

- 😀 The automatic system regulates air pressure, turning off the motor when the pressure reaches the set standard, typically between 5-6 bar.

- 😀 Air Service Units control and distribute compressed air to various channels and help manage the pressure for pneumatic systems.

- 😀 The valve is a critical component for directing airflow in the system. There are several types, including solenoid-operated valves, which help control the flow of air to different parts of the system.

- 😀 Pneumatic cylinders can be double-acting (with two ports) or single-acting (with one port) and are used to convert compressed air into mechanical motion.

- 😀 Oneway flow control valves regulate air flow in one direction, preventing reverse airflow through a bypass when necessary.

- 😀 The electrical component of the system includes power supply, buttons (push-button type), and various relays that control the pneumatic components.

- 😀 Each button or switch has specific functions, such as activating a relay or controlling the air pressure in the pneumatic system.

- 😀 Proper wiring and connections are necessary for the system's functionality. The wiring must be done carefully, ensuring correct connections to avoid malfunction.

- 😀 The system is designed to work automatically once the pneumatic setup is complete, with features like automatic shutdown and pressure control.

- 😀 A flow control system helps to adjust the speed of pneumatic cylinders by regulating the air flow, allowing for gradual extension or retraction based on system requirements.

Q & A

What is the purpose of a compressor in an electro-pneumatic system?

-The purpose of a compressor in an electro-pneumatic system is to compress air and store it in a reservoir. This compressed air is then used to power the pneumatic system.

What are the main components of a compressor?

-A compressor consists of several components, including the motor, reservoir for storing compressed air, automatic system to regulate air pressure, manometer to measure air pressure, and air service unit.

How does the automatic system of the compressor function?

-The automatic system of the compressor regulates air pressure by turning off the motor when the pressure in the reservoir reaches a preset value, typically between 5 to 6 bars.

What is the role of a manometer in an electro-pneumatic system?

-A manometer is used to measure the air pressure within the system. It helps in ensuring the air pressure stays within acceptable levels for optimal system function.

What is the purpose of an air service unit in the system?

-The air service unit regulates air pressure, removes moisture through a condenser, and lubricates the system to ensure smooth operation.

What types of valves are mentioned in the script, and how do they function?

-The script mentions several types of valves, such as the 5/2 and 5/3 solenoid valves. These valves control the flow of compressed air in the system, directing it to various components like cylinders based on input from solenoids.

What is the difference between a double-acting and a single-acting cylinder?

-A double-acting cylinder has two ports for air intake and exhaust, allowing it to extend and retract with air pressure on both sides. A single-acting cylinder uses only one port and relies on a spring for retraction when pressure is released.

What is the function of a one-way flow control valve in the system?

-A one-way flow control valve regulates the direction of air flow, ensuring that air flows in only one direction and allowing control of the speed of movement in the system.

What role does the power supply play in the electro-pneumatic system?

-The power supply, typically 24 volts in industrial settings, provides the necessary electrical power for solenoids and control elements in the electro-pneumatic system.

How is the electrical part of the electro-pneumatic system installed and connected?

-The electrical part is connected using standard wiring practices, where the components like solenoids, push buttons, and relays are wired to the system, ensuring proper operation of the pneumatic components through electrical signals.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

5.0 / 5 (0 votes)