INILAH TEKNOLOGI TERBARU UNTUK MEMBUAT PAPAN PARTIKEL! TEROBOSAN REVOLUSIONER DI INDUSTRI

Summary

TLDRThe video explores the production process of particle board, a cost-effective and eco-friendly composite material made from wood waste. It highlights the advantages of using sustainable resources and the simple manufacturing process, while also addressing the material's vulnerabilities, such as lower durability and moisture sensitivity. The detailed steps in the production, from collecting wood waste to pressing and finishing, are illustrated, showcasing the technology and quality control involved. Ultimately, the video emphasizes particle board's versatility in various applications, including furniture and construction.

Takeaways

- 😀 Particle board is a composite material made from wood shavings bonded with adhesives, making it economical and eco-friendly.

- 🌳 The production process primarily utilizes wood waste, such as sawdust and wood chips, sourced from timber processing factories.

- 🚚 Trucks transport wood waste to the particle board factory, where it undergoes several processing steps.

- 🔄 The wood waste is first ground into uniform sizes, followed by drying to reduce moisture content to 1.5%.

- ⚙️ After drying, the particles are screened to separate larger pieces, which are then ground down further.

- 🧪 The dried wood particles are mixed with resin, wax, and hardening agents to create a continuous mat.

- 🔥 The mat is compressed under heat in a hot press, activating the adhesives and bonding the particles together.

- ✂️ After cooling, the bonded sheets are cut to size and sanded for a smooth finish.

- 🔍 Quality control involves testing samples for density, strength, and adherence to specifications.

- 🎨 Some particle boards undergo a lamination process for decorative finishes, enhancing their appearance and durability.

Q & A

What is particle board, and what materials is it made from?

-Particle board, also known as partile board, is a composite material made from wood chips and shavings that are bonded together using adhesives.

What are the main advantages of using particle board?

-The main advantages of particle board are its cost-effectiveness and environmental friendliness, as it uses waste wood from the timber industry. Its production process is relatively simple, leading to lower manufacturing costs.

What are some disadvantages of particle board?

-Some disadvantages include lower durability compared to solid wood or other composites like MDF. Its structure is more susceptible to damage from moisture or excessive pressure, and it is generally not water-resistant.

How is particle board produced?

-The production process starts with collecting waste wood from sawmills. The wood is then ground into small particles, dried, screened for size, and mixed with adhesives. The mixture is pressed into sheets and cut to size.

What happens to wood waste collected from sawmills?

-Wood waste collected from sawmills is delivered to the particle board factory, where it is stored, processed into smaller sizes, dried to remove moisture, and then used in the production of particle board.

How does the drying process affect the wood particles?

-The drying process reduces the moisture content of the wood particles to around 1.5%, which is crucial for ensuring the quality and durability of the final product.

What role does the adhesive play in the production of particle board?

-Adhesive is mixed with the wood particles to bind them together during pressing. This ensures the structural integrity of the board when subjected to various stresses.

What is the significance of the quality control process?

-Quality control is essential to ensure that the particle board meets specified standards for density, strength, and other important characteristics, which are tested regularly in a laboratory.

What is the finishing process for particle board?

-The finishing process includes laminating the particle board with decorative layers to enhance its appearance and durability, as well as protecting it against UV rays and chemicals.

What are some common applications of particle board?

-Particle board is commonly used for furniture, cabinets, and laminated fixtures due to its economical nature and versatility.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Making wood as strong as steel!

Mengenal Eco Enzyme, Manfaat dan Cara Membuatnya I Sampah Organik pun Bisa Disulap jadi Eco Enzyme

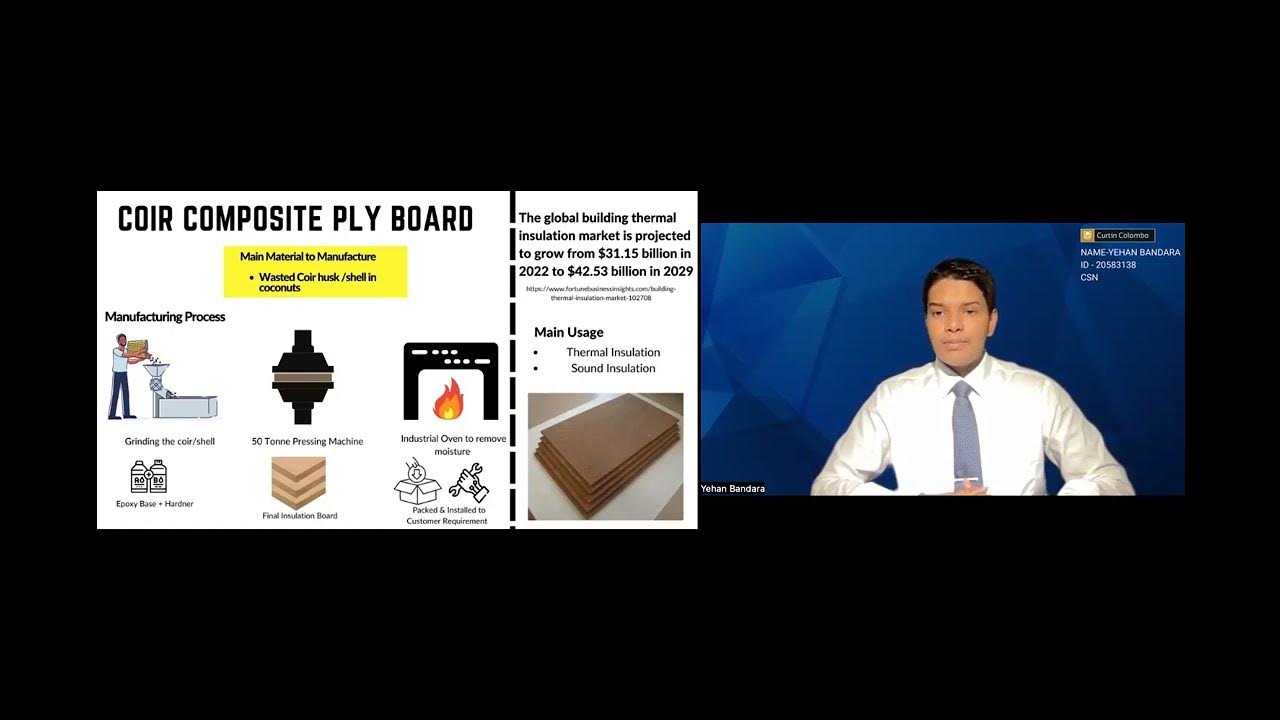

Coir Composite Board using wasted Coconut husk & Shells | MGMT 3000

Coconut Charcoal Briquettes And Their Benefits

Proses Produksi Papan Komposit / Wood Plastic Composite (WPC)

Como é a fabricação de tijolos ecológicos? Veja a visita à fábrica.

5.0 / 5 (0 votes)