PURIFIER BOWL OVERHAULING | MITSUBISHI PURIFIER SELFJECTOR BOWL OVERHAULING PROCEDURE

Summary

TLDRThis video provides a comprehensive guide to disassembling and assembling the bowl of the Mitsubishi self-check Dorjee series. It outlines the step-by-step process, including the careful handling of pipes, valves, and various components to ensure proper maintenance and avoid damage. Key steps such as releasing oil, loosening cap nuts, and inspecting pilot valves are highlighted, emphasizing the importance of cleaning and replacing parts as necessary. The video serves as an essential resource for technicians, offering detailed instructions to enhance understanding and proficiency in equipment maintenance.

Takeaways

- 🔧 Ensure to subscribe and enable notifications for updates on the disassembly procedure.

- 🔌 Disconnect connecting pipes carefully, noting that configurations may vary by supplier.

- 💧 Release oil from the piping before starting disassembly to avoid spills.

- 🔩 Remove cap nuts from the oil inlet and outlet pipes by turning them horizontally.

- ⚡ Handle electrical wiring with caution when dealing with pressure sensors on outlet pipes.

- 🔨 Use a wrench to loosen cover nuts, and a plastic hammer to tap the inlet pipe for easier removal.

- 🛠️ Mount a lifting jack to the upper hood thread to lift the sludge cover carefully.

- 🌊 Remove components like the heavy and light liquid chambers without damaging any parts.

- 🔍 Inspect and clean pilot valves and O-rings to ensure they are not hardened or damaged.

- 🧼 Use soft utensils for cleaning sensitive parts and avoid metal tools to prevent scratches.

Q & A

What is the purpose of disassembling the bowl in the Mitsubishi self-check Dorjee series?

-Disassembling the bowl is necessary to prevent excessive force on the bearings of fast-rotating equipment and to perform maintenance and inspections.

What safety precautions should be taken when disconnecting the connecting pipes?

-Ensure to remove the plug to release oil safely, and be cautious of electrical wiring, especially if the outlet pipe is equipped with a pressure sensor.

What tools are required for loosening the disk nuts during disassembly?

-A disk nut handle is required to loosen the disk nuts, along with a wrench for removing cover nuts and a cap nut spanner for loosening cap nuts.

How should the sludge cover be lifted during disassembly?

-Mount the lifting jack onto the thread of the upper hood and use a chain block to slowly lift the sludge cover.

What is the importance of the gravity disk during disassembly?

-The gravity disk can be replaced during disassembly, and it plays a critical role in the function of the bowl assembly.

What should be avoided when cleaning the removed discs?

-Do not use metal or sandpaper to clean the discs, as scratches can cause sludge to accumulate more quickly. Instead, soak them in cleaning oil or detergent and use soft utensils.

What is the process for removing the pilot valves?

-To remove the pilot valves, unscrew the valve nut, use jack bolts to release the valves, and take care not to damage the nylon valve sheets.

What is the recommended method for installing the main seal ring?

-Clean the grooves thoroughly, align the main seal ring, and gently insert it without striking it directly with a hammer to avoid damage.

What is the role of the bowl lifting jack during the assembly process?

-The bowl lifting jack is used to separate the bowl from the vertical shaft and assist in the safe handling and positioning of the bowl during assembly and disassembly.

Why is it important to inspect the o-rings during maintenance?

-Inspecting the o-rings is crucial because hardened or damaged o-rings can obstruct the opening and closing of the valves, leading to operational issues.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

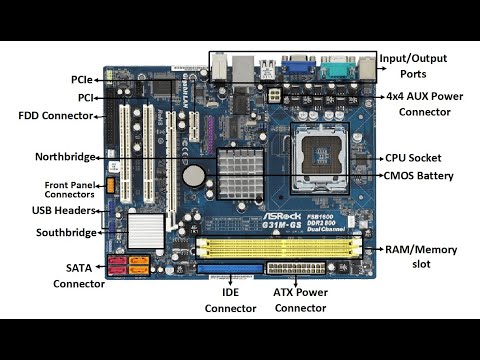

How to Disassemble/Assemble a Computer System Unit? - Basic Parts and Function

Pre-operative Check Up of Farm Tools, Implements and Equipment

English video assignment how to dismantle and install Transmission Overhaul

HWFLY Lite or PICOFLY Lite??

Working a Money Bowl || A Crash Course on Money Magic

Reimbursements

5.0 / 5 (0 votes)