How does a Steam Turbine Work?

Summary

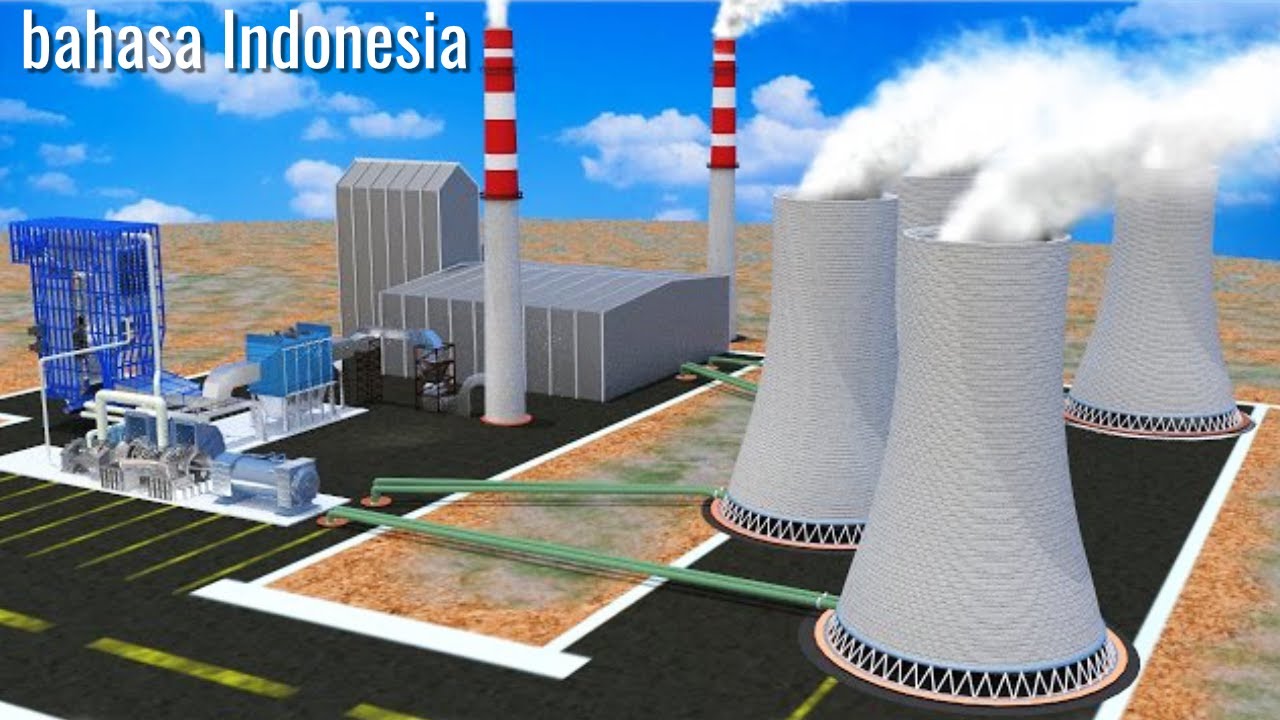

TLDRThis video explains the inner workings of steam turbines in nuclear and coal-based thermal power plants. It explores how steam turbines convert thermal energy into mechanical energy using airfoil-shaped blades that create lift force. The video also discusses fluid energy, the role of stators in increasing fluid velocity, and the concept of 'degree of reaction,' which helps define turbine types. Additionally, it covers the importance of reheating steam to boost power plant efficiency, and the role of a governing mechanism to maintain constant turbine speed, crucial for synchronized power generation.

Takeaways

- ⚡ Nuclear and coal-based thermal power plants generate nearly half of the world's power.

- 🔄 The core of these power plants is the turbine, which converts thermal energy from steam into mechanical energy.

- 🌀 Steam turbine blades are airfoil-shaped to create a pressure difference and produce lift, rotating the turbine.

- 💨 Fluid energy in a steam turbine includes speed, pressure, and temperature, all of which decrease as the blades absorb energy.

- 🚀 A stator section acts like a nozzle to increase the fluid's velocity, enhancing kinetic energy while reducing pressure and temperature.

- 🔧 Multiple stages of rotors and stators are used to efficiently convert steam energy into mechanical energy.

- 📊 The degree of reaction is an important design metric, dividing enthalpy (pressure and temperature energy) by total energy change.

- 📏 To handle expanding steam, the blades towards the turbine's outlet are much longer to accommodate increased flow area.

- 🔥 Reheating the steam after the first stage increases its temperature and improves overall power plant efficiency.

- ⚙️ A governing mechanism regulates steam flow to maintain constant turbine speed, ensuring stable electricity production.

Q & A

What role do turbines play in nuclear and coal-based thermal power plants?

-Turbines in nuclear and coal-based thermal power plants convert thermal energy from steam into mechanical energy, which is essential for generating electricity.

Why are steam turbine blades shaped like airfoils?

-Steam turbine blades are shaped like airfoils to create a pressure difference when high-energy steam passes over them, generating a lift force that rotates the turbine.

How does a fluid’s energy change as it passes through the turbine blades?

-As fluid passes through the turbine blades, it loses energy in three forms: speed, pressure, and temperature. This energy transfer converts the fluid's energy into mechanical energy, reducing the velocity and energy of the fluid.

What is the purpose of the stator in a steam turbine?

-The stator is a stationary component that acts like a nozzle, increasing the velocity of the fluid by reducing the flow area. It also ensures that the fluid exits at an optimum angle to maximize efficiency in the next rotor stage.

Why are multiple stages of rotors and nozzles used in steam turbines?

-Multiple stages of rotors and nozzles are used to gradually reduce the pressure and temperature of the steam, allowing the turbine to efficiently convert thermal energy into mechanical energy over a series of stages.

What is the 'degree of reaction' in the context of steam turbines?

-The degree of reaction is the ratio of pressure and temperature energy change (enthalpy) to the total energy change in the rotor. It determines the type and design of a steam turbine.

Why are the blades of steam turbines longer towards the outlet?

-The blades are longer towards the outlet to accommodate the increased volume of steam as its pressure decreases. This prevents the flow speed from becoming too high, maintaining efficient operation.

How does reheating increase the efficiency of steam turbines in power plants?

-Reheating increases efficiency by adding more heat to the steam after it has passed through the first stage, raising its temperature again, which leads to a higher overall power output and efficiency.

How is the speed of the steam turbine regulated to maintain consistent electricity frequency?

-A steam flow governing mechanism adjusts the steam flow rate depending on the turbine speed. If the turbine rotates too fast, the control valve reduces the steam flow, and if it's too slow, the valve increases it to maintain a constant speed and frequency.

Why is it important to maintain a constant speed in steam turbines?

-Maintaining a constant speed is crucial because the frequency of the electricity generated is directly proportional to the turbine's speed. Variations in speed can affect the stability and synchronization of the power supply.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

¿Cómo funciona una turbina de vapor?

Bagaimana cara kerja pembangkit listrik tenaga termal/uap?

How does a Thermal power plant work?

Como funciona uma usina termoelétrica?

Sources of Electricity | Where does Electricity come from? | Letstute

Video Animasi Pembangkit Listrik Tenaga Nuklir (PLTN) dalam versi English

5.0 / 5 (0 votes)