Pipe Rack Design Project Overview

Summary

TLDRThis video provides a comprehensive overview of the project workflow in the oil and gas industry, broken down into nine key steps. It covers the entire process, from project kickoff with interdisciplinary meetings to final quality assurance and review. Key phases include basic engineering, design, preliminary data submission, load verification, and detailed design. The video highlights the iterative collaboration between piping, civil, structural, electrical, and mechanical teams to ensure accurate and efficient project execution. It concludes with a focus on construction and quality assurance. Upcoming sessions will delve deeper into essential inputs from various engineering disciplines.

Takeaways

- 📈 The project workflow in the oil and gas industry is divided into nine segments, each crucial for project execution.

- 🚀 The project starts with a kickoff meeting involving all key engineering disciplines to align objectives, timelines, and data requirements.

- 🛠️ The basic engineering and design phase involves creating initial layouts, estimating pipe sizes, and determining primary and secondary lines.

- 📊 Preliminary data submission includes estimating pipe weights, insulation contents, and thermal allowances for civil and structural teams.

- 📐 Preliminary drawings are developed using initial input to create foundation designs and structural member sizes, which help in estimating material quantities.

- 🔄 Load data is continually refined through an iterative process between piping, stress, and civil teams to ensure accuracy.

- 📑 The detailed design phase finalizes foundation designs, structural member sizes, and construction drawings, including safety and future expansion considerations.

- 🏗️ Construction documentation is prepared and issued to the construction team to execute the building of the pipe rack on site.

- 🔧 The project execution phase involves the construction team building the pipe rack, with ongoing support from engineering teams to resolve any issues.

- ✅ The final phase is quality assurance and review, ensuring all safety, regulatory, and operational requirements are met before project completion.

Q & A

What is the first step in the oil and gas project workflow?

-The first step is the project kickoff, which involves a meeting between all key engineering disciplines such as piping, civil, structural, underground (UG) teams, electrical, instrument, mechanical, and process teams. The goal is to align objectives, timelines, and initial data requirements for the project.

What is the role of the piping team during the basic engineering and design phase?

-During the basic engineering and design phase, the piping team develops an initial layout and estimates pipe sizes, routes, and general arrangements. They also identify primary and secondary lines and the preliminary loads on the structure, which help determine the piping rack geometry and overall plant layout.

What data does the electrical and instrument team provide during the design phase?

-The electrical and instrument team provides data on cable tray layouts, equipment placements, and other specific electrical and instrument requirements for the project.

What is the significance of the preliminary data submission phase?

-In the preliminary data submission phase, the piping team submits estimated loads and preliminary layout data to the civil and structural teams. This data includes pipe weights, insulation contents, and thermal expansion or contraction allowances, which are used by civil and structural teams to create the primary designs for the foundation and structural members of the pipe rack.

What happens during the development of preliminary drawings?

-Using the estimated loads and initial input data, the civil and structural teams create preliminary drawings, including foundation designs (open or pile foundation) and structural member sizes. These drawings are also used to estimate the bill of quantities for the required materials.

What is the purpose of load data verification and adjustment?

-As more accurate data becomes available, the piping and stress teams refine their load estimates and provide updated information to the civil and structural teams. This iterative process ensures that all disciplines work with the most accurate data to complete the project.

When does the project enter the detailed design phase?

-Once sufficient data is available, the project moves into the detailed design phase, where the civil and structural teams finalize foundation designs, structural member sizes, and construction drawings. Safety, regulatory, and future expansion requirements are also taken into account.

What documents are prepared during the construction documentation phase?

-In the construction documentation phase, final construction documents are prepared, including detailed drawings and specifications. These documents are issued to the construction team for execution on-site.

What happens during the project execution and construction phase?

-During this phase, the construction team begins building the pipe rack based on the finalized design documents. Engineering teams continue to provide support on-site, resolving any issues that arise during construction.

What is the final step in the project workflow?

-The final step is quality assurance and final review, where the project undergoes quality checks and a final review to ensure it meets all safety, regulatory, and operational requirements.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

Diagram Alir Proses Pembuatan Minyak Bumi

Overview of Power Distribution in the Oil and Gas Industry (Part-1)

Introduction to the Oil and Gas Sector

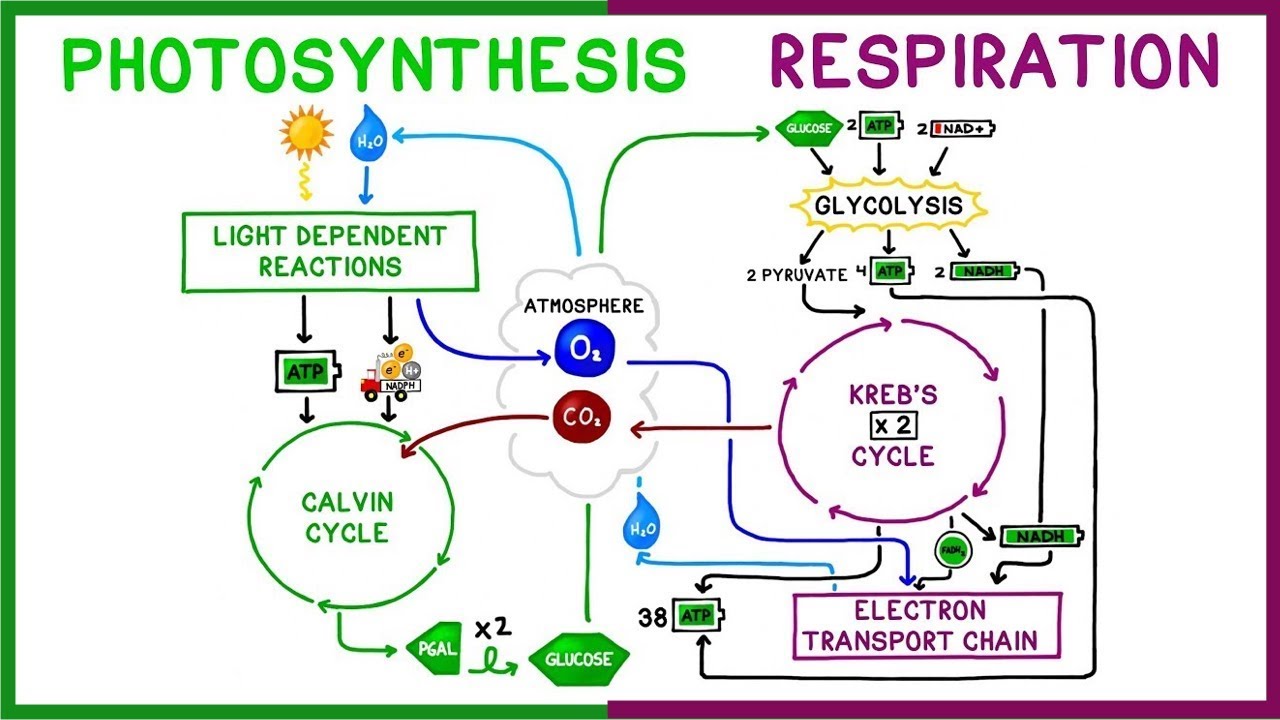

Photosynthesis vs. Cellular Respiration Comparison

How to Create a Project Timeline: A Practical Guide

Basic Well Completion, Perforation, Stimulation & Sand Control

5.0 / 5 (0 votes)