Electronic Soldering Instruction - Heathkit

Summary

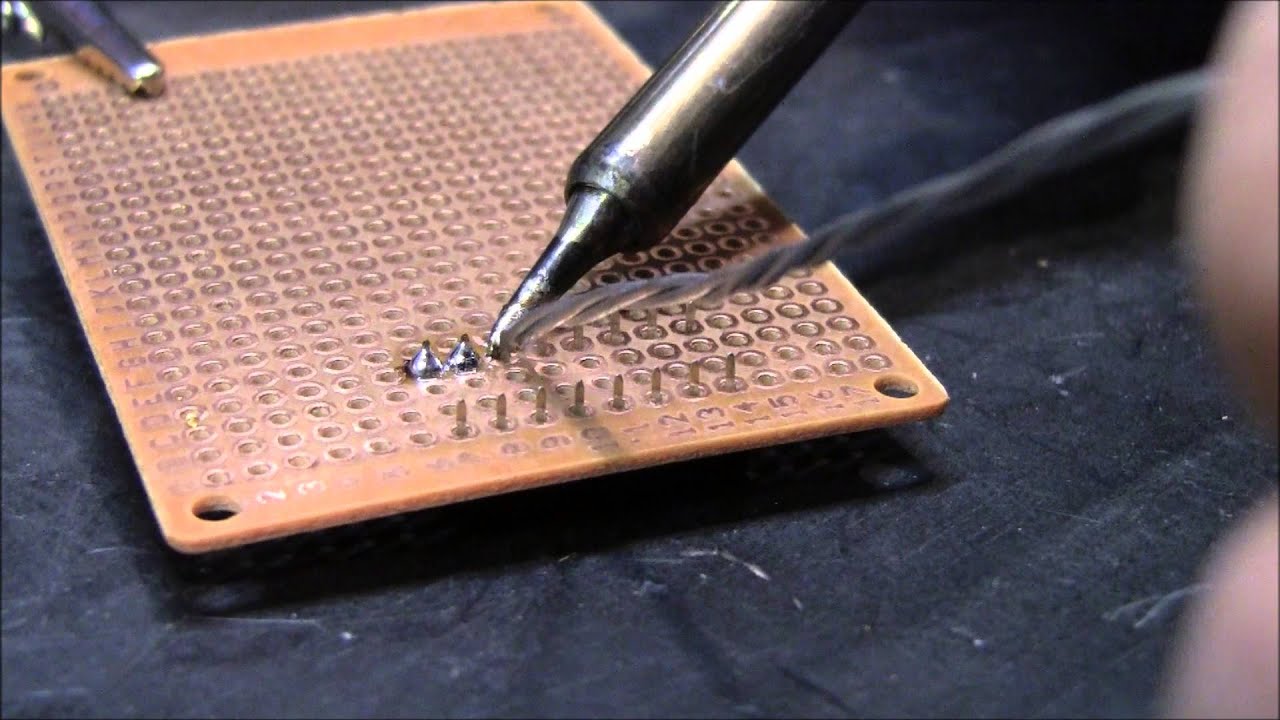

TLDRThis soldering course educates on the composition and application of solder, highlighting its importance in creating strong, low-resistance electrical connections. It covers the properties of 60/40 solder, the use of flux to ensure clean connections, and the selection of appropriate soldering tools. The script also details proper soldering techniques, the avoidance of common mistakes like cold solder joints and solder bridges, and emphasizes safety practices. Additionally, it introduces advanced soldering methods for various electronic components, emphasizing the need for clean, efficient, and safe soldering processes.

Takeaways

- 🔧 Solder is a crucial component in electronics, providing both physical and electrical connections that are vital for the operation of machinery and devices.

- 🔩 The composition of solder is primarily tin and lead, with the ratio determining the melting point, with 60/40 being a common choice for electronics due to its low melting point and quick hardening.

- 🌡️ Soldering involves heating solder to a plastic state where it can be molded and then solidified to create a strong bond, with the process temperature carefully controlled to ensure quality connections.

- 💧 Flux is essential for soldering as it removes oxidation from surfaces, allowing solder to adhere properly and create a good electrical and physical connection.

- 🔩 Rosin flux is the preferred type for electronics due to its non-corrosive nature and non-conductive properties once cooled, making it safe for sensitive components.

- 🛠️ The right soldering iron is key, with a 25-30 watt pencil iron being ideal for most electronic soldering tasks due to its precision and temperature control.

- 🏗️ Soldering techniques include proper heat application, using the right amount of solder, and ensuring clean and secure connections to prevent weak points in the circuit.

- 🔍 Inspection of soldered connections is crucial to identify and correct issues like cold solder joints, rosin joints, and solder bridges that can cause malfunctions.

- 🛡️ Safety is paramount in soldering, with the use of safety glasses to protect against hot solder splashes and careful handling of hot tools to prevent burns.

- ⚙️ Professional soldering techniques can enhance the quality and efficiency of soldering work, including the use of heat sinks, proper solder application, and maintaining a clean soldering iron for optimal performance.

Q & A

What is the primary objective of the soldering course described in the script?

-The primary objective of the soldering course is to teach what solder is, how it works, and how to use it effectively to make good solder connections.

Why is soldering important for electronic circuits?

-Soldering is important for electronic circuits because it provides a secure way of joining thousands of components, which is crucial for the proper functioning of electronics, including intricate and failsafe circuits that can be life-dependent.

What are the two main advantages of soldering as a joining method for electronic components?

-The two main advantages of soldering are that it provides a good physical connection, which can be as strong as the metal surface itself, and it offers a good electrical connection with very little resistance to current flow.

What is the composition of solder and how does the tin-lead ratio affect its properties?

-Solder is an alloy of tin (Sn) and lead (Pb). The tin-lead ratio affects the solder's melting point and physical strength. For example, a 60/40 solder is 60% tin and 40% lead, and it melts at a lower temperature than either metal alone.

Why is flux used in soldering, and what are the differences between acid and rosin flux?

-Flux is used in soldering to remove oxidation from surfaces, allowing the solder to make a clean connection. Acid flux is corrosive and can damage circuits or conduct electricity, while rosin flux does not have these disadvantages, making it the preferred type for electronic circuits.

What is the recommended soldering iron wattage for most electronics work?

-A 25 to 30 watt pencil iron is recommended for most electronics work as it provides a tip temperature of 650 degrees Fahrenheit, which is suitable for 90% of all electronics soldering tasks.

How can one avoid cold solder connections and what do they look like?

-To avoid cold solder connections, ensure the solder is heated above the plastic range. Cold solder connections look dull and crystallized, and they may be physically weak with high electrical resistance.

What is a rosin joint in soldering and how can it be identified?

-A rosin joint is a type of bad connection caused by insufficient heating of rosin core solder, which can leave rosin inside the connection and create an open circuit. It can be identified by reheating the joint without adding solder and watching for a bit of smoke as the rosin boils away.

How should one inspect soldered connections to ensure they are of good quality?

-Good soldered connections should be shiny and smooth, with solder that has flowed evenly and settled in the surface pores. Each wire lead should extend through the solder, and there should be no movement when pressure is applied to the connection.

What safety precautions should be taken while soldering?

-Safety precautions include wearing safety glasses to protect against hot solder splashes, treating solder and soldering tools with respect, and being cautious to avoid burns. Additionally, one should practice good soldering techniques to minimize risks.

Outlines

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantMindmap

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantKeywords

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantHighlights

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantTranscripts

Cette section est réservée aux utilisateurs payants. Améliorez votre compte pour accéder à cette section.

Améliorer maintenantVoir Plus de Vidéos Connexes

5.0 / 5 (0 votes)