7 FATAL Wiring Mistakes Most DIYers Don't Know They Are Making | Most Are Guilty of 3

Summary

TLDRThe video covers common wiring mistakes DIYers make, including not properly twisting wires before capping them, overloading or using the wrong size wire nuts, and improperly connecting solid and stranded wires. It advises pre-twisting wires before adding a wire nut to ensure a tight connection not reliant on the nut itself. It also recommends using name-brand wire nuts, noting the size and number of wires they can handle. For solid-stranded connections, it suggests ensuring the stranded wire is slightly longer and wraps the solid wire when twisted. It also demonstrates issues with push-in Wago connectors coming loose.

Takeaways

- 😲 Most people improperly twist wires together, risking a loose connection over time.

- 😤 Always follow manufacturer instructions for twisting wires with wire nuts.

- 😊 Pre-twisting wires before adding a wire nut creates a tighter connection.

- 😡 Using the wrong size wire nut can overload it or make connections loose.

- 😱 Stranded and solid core wires are commonly connected poorly.

- 👍 Properly secure stranded wire longer to wrap solid core wire when using wire nuts.

- 😨 Wago connectors get accidentally opened when pushing into boxes.

- 😫 Wago connectors with too much or too little wire exposed can lose connection.

- ✅ Use the built-in strip gauge on Wago connectors.

- 🤓 Making proper wire and device connections avoids electrical issues.

Q & A

What is the most common wire connection mistake made by DIYers and electricians?

-The most common mistake is to simply twist on a wire nut without properly twisting and connecting the wires first, relying solely on the wire nut to make the connection. This can lead to a loose connection that fails over time.

Why is pre-twisting wires before adding a wire nut recommended?

-Pre-twisting the wires before adding the wire nut forms a tight joint between the wires so they are connected even if the wire nut comes off. This provides support and ensures good surface contact between the wires.

What should you do if a wire nut seems too small or too large for the wires you need to connect?

-Refer to the wire nut packaging, which provides a bar graph listing the exact wire sizes and quantities that each colored wire nut can accommodate, including minimums and maximums.

Why is connecting solid core and stranded wires tricky?

-When twisted together, stranded wires tend to slip below solid core wires rather than wrapping tightly together. Special care must be taken to position the wires correctly before adding the wire nut.

How can Wago lever nuts simplify connecting solid and stranded wires?

-Wago lever nuts don't require the wires to be twisted. Flipping the lever secures the wires neatly in place without one slipping below the other.

What common Wago mistakes should you avoid?

-Avoid stripping too much or too little insulation. Use the built-in strip gauge for the right amount. Also cover levers with tape when pushing into boxes to prevent wires releasing accidentally.

Why might a voltage detector show power flowing but a device not turn on?

-If insulation is not stripped back far enough in a Wago connection, you may read voltage but not enough current flow to power the device.

What should you do when installing receptacles and switches?

-Refer to the video linked at the end for tips on avoiding mistakes when installing receptacles and switches and how to do it properly.

What are some key things DIYers should keep in mind when making wire connections?

-Always follow manufacturer instructions, pre-twist wires when possible, use quality wire nuts suited to the wire gauge and quantity, and take care when mixing stranded and solid core wires.

Where can I find more tips on properly connecting wires?

-Check the linked video near the end for mistakes to avoid when installing receptacles and switches. Also leave comments with any questions!

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

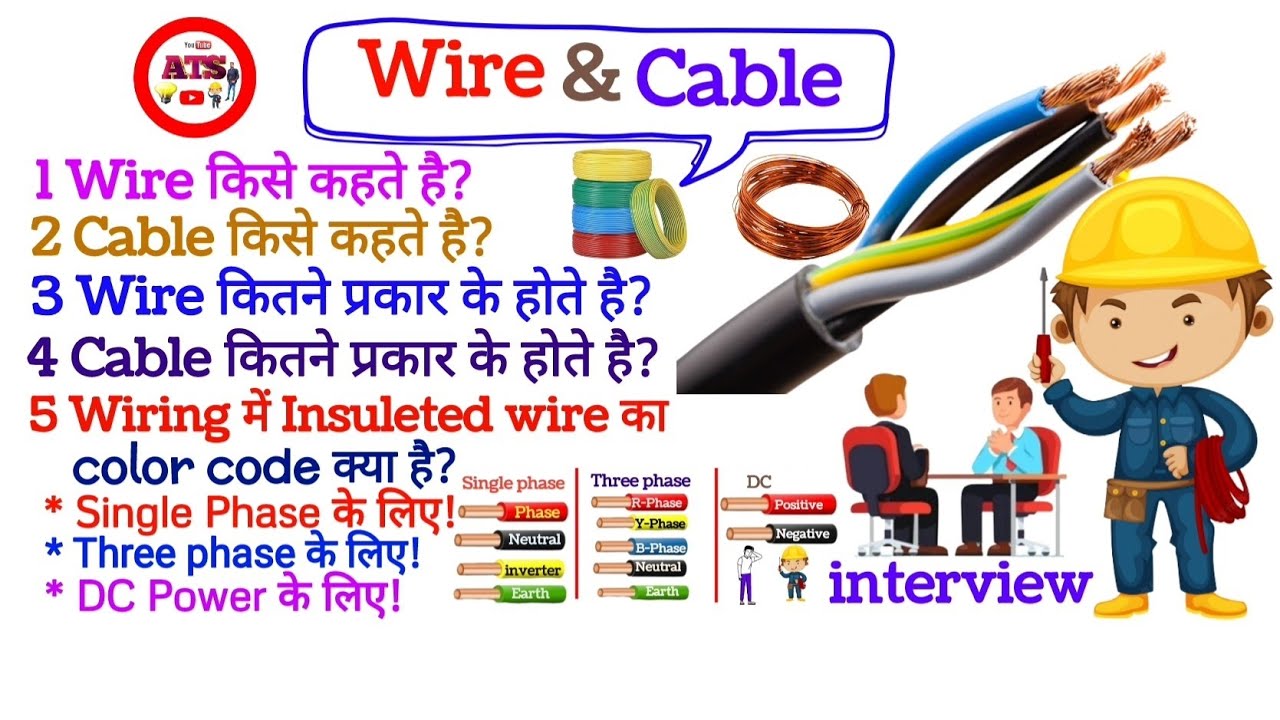

Type of cable & wire, wire and cable different, Wire color code in India interview Question & Answer

I Discovered This Hidden Wiring Trick In An Old Forum!

Wiring Switches

Cara pasang kabel LAN (pasang konektor RJ45 ke kabel UTP) dengan konfigurasi Straight

RV TT 30R Outdoor Enclosed Power Panel PAULINN

10 Common Mistakes DIYers Make In Circuit Breaker Boxes

5.0 / 5 (0 votes)