KETAHANAN ENERGI INDONESIA l BIODIESEL

Summary

TLDRThis video highlights Indonesia's efforts in ensuring energy security through biodiesel production from palm oil. With over 13 million hectares of oil palm plantations, the country produces 46 million tons of crude palm oil annually. The government has introduced biodiesel blending programs, such as B30, to reduce reliance on imported fuel and decrease greenhouse gas emissions. The process involves refining CPO, transesterification, and purification to produce biodiesel. Indonesia’s biodiesel production has not only bolstered domestic fuel consumption but also supported economic growth, created jobs, and contributed to environmental sustainability.

Takeaways

- 😀 Indonesia has 13 million hectares of oil palm plantations, producing around 46 million tons of palm oil annually.

- 😀 Biodiesel, produced from palm oil, is a key element in Indonesia's energy security strategy, with a goal to increase biodiesel blends from B20 to B30 and eventually B100.

- 😀 The government's energy policy aims to increase renewable energy usage, targeting a 23% renewable energy mix by 2025.

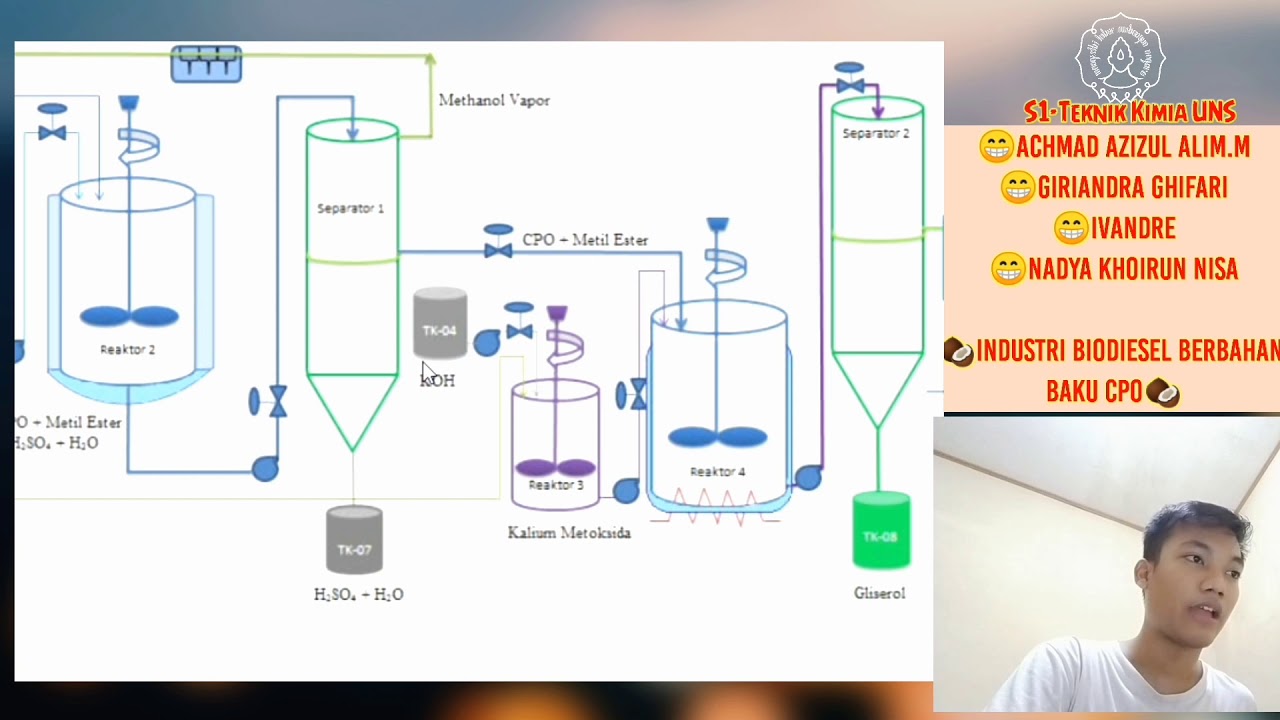

- 😀 Biodiesel is produced through transesterification, a process that converts palm oil (CPO) into biodiesel by mixing it with methanol and a base catalyst.

- 😀 Palm oil processing involves stages like harvesting, sterilizing, crushing, and pressing fresh fruit bunches to produce crude palm oil (CPO).

- 😀 The biodiesel production process from CPO also generates by-products like palm kernel oil, palm shell, and fiber, which have additional commercial uses.

- 😀 The quality of CPO directly affects the biodiesel quality, with the biodiesel production process requiring careful refinement to ensure high standards.

- 😀 There are three main biodiesel blending methods: inline blending, tank blending, and splash blending, all of which are used to mix biodiesel with diesel fuel.

- 😀 Biodiesel quality is regulated by Indonesian National Standards (SNI), including parameters like viscosity, flash point, and free alkyl glycerol esters.

- 😀 The B30 program, implemented in Indonesia, has led to positive environmental impacts, including the reduction of greenhouse gas emissions by an estimated 22.3 million tons of CO2 in 2020.

Q & A

What is the current annual production of oil palm plantations in the country?

-The country currently has 13 million oil palm plantations producing approximately 46 million tons annually.

What is the significance of the B30 biodiesel in Indonesia's energy strategy?

-B30 biodiesel, which is a blend of 70% diesel fuel and 30% biodiesel, plays an important role in enhancing energy security by reducing the reliance on imported fuels and supporting national energy independence.

How is biodiesel produced from palm oil?

-Biodiesel is produced from palm oil through a process called transesterification, where the palm oil undergoes a chemical reaction with methanol, catalyzed by a base like NaOH or KOH, to produce fatty acid methyl esters (FAME), which is biodiesel.

What raw materials are commonly used in biodiesel production in Indonesia?

-In Indonesia, biodiesel is mainly produced from palm oil, also known as crude palm oil (CPO), due to its high potential and productivity.

What are the key stages in the palm oil processing to produce biodiesel?

-The key stages include harvesting the palm fruit, processing it into crude palm oil (CPO), refining the CPO into refined oil, conducting transesterification to produce biodiesel, and then purifying the biodiesel before distribution.

What is the role of the transesterification process in biodiesel production?

-Transesterification is the chemical reaction that converts triglycerides (fats and oils) into biodiesel by reacting with methanol and a base catalyst. This process results in the formation of biodiesel (FAME) and glycerol.

How does the refining process affect the quality of biodiesel?

-The refining process, which includes degumming, bleaching, and deodorizing the CPO, improves the quality of the biodiesel by removing impurities such as excess moisture, dirt, and odor, ensuring a higher-grade final product.

What by-products are produced during the palm oil processing that can be used in other industries?

-By-products such as palm kernel oil, empty fruit bunches, and fiber can be used as raw materials for various industries, including fertilizers, biomass fuel, and even bioactive compounds like vitamin E and squalene.

What are the environmental benefits of using biodiesel in Indonesia?

-Using biodiesel reduces greenhouse gas emissions, with estimates suggesting a reduction of 22.3 million tons of CO2 equivalent in 2020. It also reduces the need for fuel imports and helps save foreign exchange.

How does Indonesia ensure the quality of biodiesel used for blending with diesel?

-Indonesia follows the Indonesian National Standard (SNI) for biodiesel quality, which includes parameters such as kinematic viscosity, flash point, corrosion rate, and sulfur content to ensure the biodiesel meets required specifications for performance and safety.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahora5.0 / 5 (0 votes)