Getting Started with Simulink, Part 2: How to Add a Controller and Plant to the Simulink Model

Summary

TLDRThis video script walks through the process of building a simple plant control model using Simulink. It demonstrates how to add, modify, and manage blocks like transfer functions, PID controllers, and signal sources. The script explores open-loop and closed-loop control, highlighting the steps to improve system performance. It also explains how to comment out parts of the model for experimentation and adjustments. While the model is simple, the tutorial covers important concepts such as signal routing, error calculation, and optimizing connections, aiming to enhance the user’s understanding of control systems simulation.

Takeaways

- 😀 Use of shift drag to add blocks in Simulink for model building.

- 😀 Blocks in Simulink can be deleted or commented out, allowing for flexible simulation setups.

- 😀 Commented-out blocks are ignored during simulation but can be easily reactivated later.

- 😀 The transfer function is a common component in plant modeling, available in the continuous library.

- 😀 You can change the coefficients of transfer functions to modify their behavior (e.g., making a first-order transfer function second-order).

- 😀 Signal routing in Simulink can be automated to avoid block intersections, making models cleaner.

- 😀 PID controllers can be added between the plant and source for feedback control.

- 😀 Simulink automatically creates connections if signals are aligned with the appropriate ports.

- 😀 A sine wave input is replaced by a step input for more predictable control in the simulation.

- 😀 Open-loop systems in simulations provide initial observations, but closed-loop control yields better results.

- 😀 Adding a summing block helps calculate the error between the input and output to optimize control signal behavior.

Q & A

What is the purpose of the plant control model described in the script?

-The purpose is to demonstrate how to create a basic plant control model using Simulink, including building both an open-loop and closed-loop system to control a plant using a PID controller.

What does the term 'shift drag' refer to in the context of Simulink?

-'Shift drag' refers to holding down the shift key while dragging a block with the mouse in Simulink. This allows you to add multiple blocks or create copies of existing ones in the model.

Why would someone use the 'comment out' feature in Simulink?

-The 'comment out' feature allows you to temporarily disable a block in the model without deleting it. This is useful for testing alternatives or keeping a reference for future use.

How does Simulink handle signal connections between blocks?

-Simulink automatically creates connections between blocks when their ports are aligned correctly. This smart routing ensures that signals flow correctly between the connected blocks.

What changes were made to the plant transfer function in the example?

-The initial plant transfer function was a first-order system, which was modified to a second-order system by changing the denominator coefficients to '1 5 6'.

What is the role of the PID controller in the model?

-The PID controller is used to regulate the plant's behavior by adjusting the control signal based on the error between the input reference and the plant's output.

Why is the sine wave signal replaced with a step block in the model?

-The sine wave is replaced with a step block to provide a more realistic and easier-to-track input signal for the system, making it easier to observe how the plant responds to a sudden change in input.

What does converting the system from open-loop to closed-loop control involve?

-Converting the system to closed-loop control involves adding a summing block to compute the error between the input and output signals. The error is then used to adjust the control signal sent to the plant, ensuring better regulation of the system.

Why is the summing block necessary in the closed-loop system?

-The summing block is necessary to calculate the error signal, which is the difference between the reference input and the plant's output. This error is then used to adjust the PID controller's behavior.

What is the significance of the feedback loop in control systems?

-The feedback loop is critical in control systems because it allows the system to adjust its behavior based on the actual output, rather than just the input. This ensures more accurate control and the ability to correct errors automatically.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Simulink Control Systems and PID, Matlab R2020b

How to Design Load Frequency Control using Simulink ? | Dr. J. A. Laghari

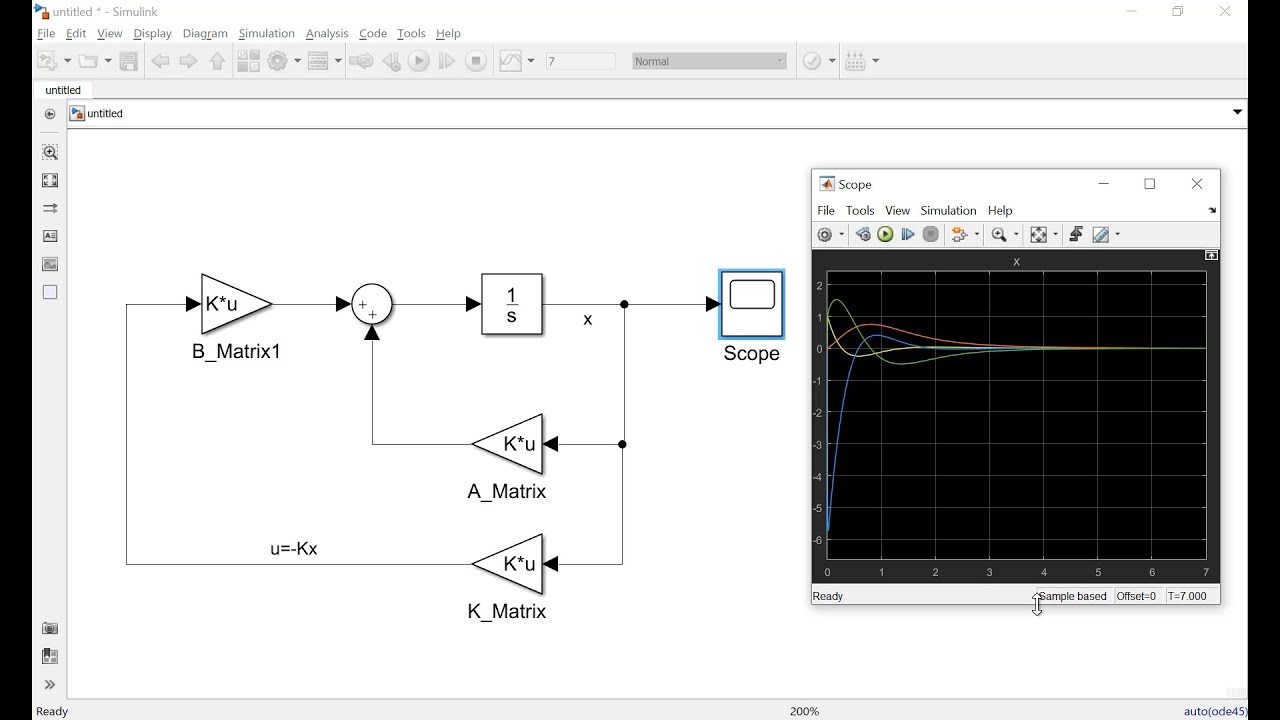

How to Make Simulation of Inverted Pendulum (Balancing Robot) Control in Simulink Matlab

Tuning PID di Simulink

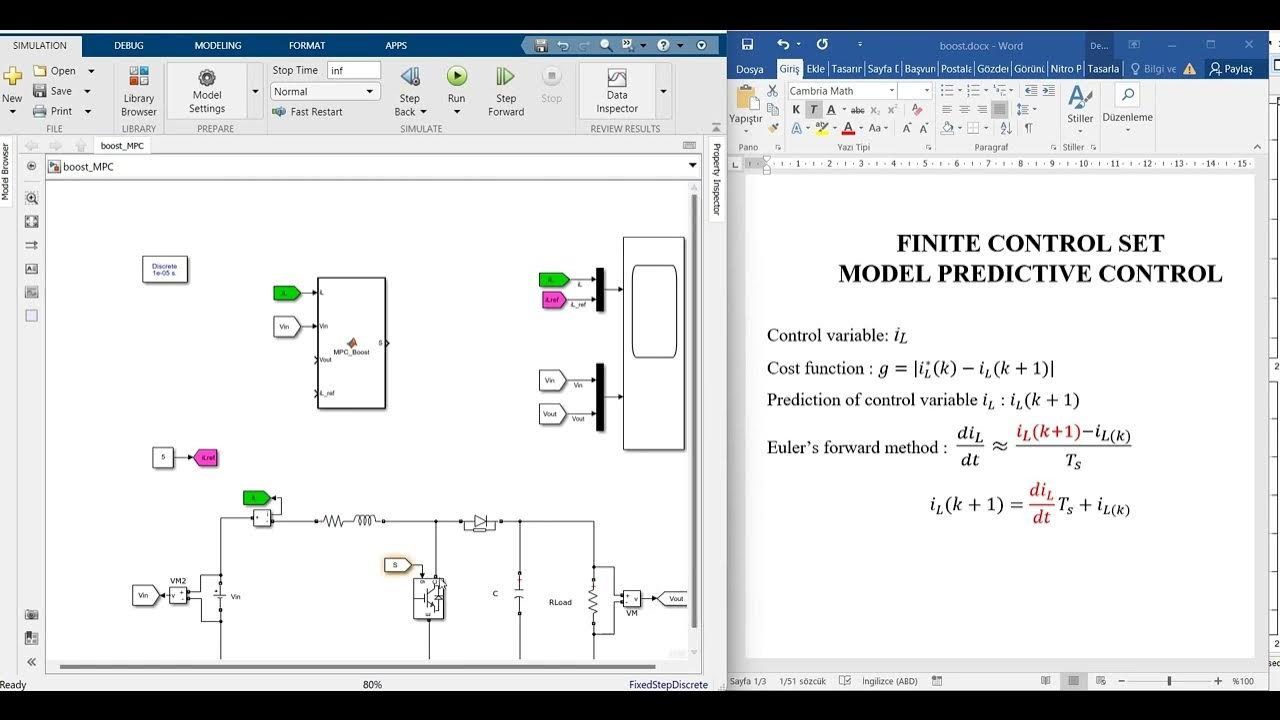

Model Predictive Control of Boost Converter

How To Design Automatic Voltage Regulator (AVR) Model of Power System in MATLAB/SIMULINK Software ?

5.0 / 5 (0 votes)