Simulation of cumene (Isopropyl Benzene) production | Aspen Hysys V10

Summary

TLDRThis video provides a detailed walkthrough of a simulation for the production of cumin (isopropyl benzene), focusing on the chemical processes involved. The video covers the main alkylation reaction where benzene reacts with propylene to form cumin, along with a side reaction producing diisopropyl benzene. Key steps include defining feed components, reactor setup, heat exchangers, and distillation columns for product separation. The process uses a PFR reactor with ammonium chloride as a catalyst and emphasizes pressure, temperature control, and reflux ratios for successful separation. The video also touches on benzene recycling and offers a future tutorial on distillation shortcuts.

Takeaways

- 😀 The video demonstrates the simulation of cumin (isopropyl benzene) production from benzene (C6H6) and propylene (C3H6).

- 😀 The main reaction in the simulation involves the alkylation of benzene with propylene to form cumin, which occurs in the vapor phase.

- 😀 A side reaction produces diisopropyl benzene (DIPB), also in the vapor phase.

- 😀 Parameters such as temperature, pressure, and composition for both benzene and propylene are critical for the reaction setup.

- 😀 Pressure adjustments are necessary for both benzene and propylene streams to ensure consistent reactions.

- 😀 The simulation uses a PFR reactor for the main alkylation reaction, with details provided for reactor dimensions and catalyst used (ammonium chloride).

- 😀 The system incorporates a heat exchanger to adjust temperatures and optimize conditions before entering the reactor.

- 😀 After the reactor, the product mixture undergoes separation through a distillation column, where the reflux ratio is adjusted for optimal product yield.

- 😀 The distillation column separates cumin and diisopropyl benzene based on their boiling points, with cumin being the lighter product.

- 😀 A recycling process is implemented to return unreacted benzene back to the mixer, increasing overall process efficiency.

- 😀 The video emphasizes the importance of reaction kinetics and the role of the PFR reactor in the production process.

- 😀 The presenter offers to create a tutorial for viewers interested in more advanced distillation column calculations and shortcuts.

Q & A

What is the main reaction in the cumin production process?

-The main reaction is the alkylation of benzene (C6H6) with propylene (C3H6) to form cumin (isopropyl benzene). This is the primary reaction occurring in the first reactor.

What is the side reaction that occurs in cumin production?

-The side reaction involves the formation of diisopropyl benzene, which occurs when cumin (isopropyl benzene) reacts with propylene (C3H6). This reaction also takes place in the vapor phase.

What catalyst is used in the production of cumin?

-Ammonium chloride is used as the catalyst in the production of cumin through alkylation.

What is the role of the heat exchanger in this process?

-The heat exchanger is used to control the temperature of the streams by either heating or cooling them as they move through the system, ensuring optimal conditions for the reactions.

How is the pressure managed during the reaction process?

-Pressure is carefully controlled, with the pressure for both benzene and propane being increased from 11.6 bar to 31.5 bar to ensure consistent reaction conditions. The pressure is also maintained within specific limits in various sections like the heat exchanger, reactor, and distillation column.

What is the significance of the PFR reactor in this simulation?

-The PFR (Plug Flow Reactor) is used because the alkylation reaction is kinetic in nature, and a PFR provides the required conditions for efficient reaction kinetics in the production of cumin.

What is the function of the distillation columns in this process?

-The distillation columns are used to separate the products based on their boiling points. The first column recycles benzene, while the second separates cumin and diisopropyl benzene, with cumin being recovered at the top of the column.

Why is the reflux ratio important in the distillation process?

-The reflux ratio is crucial because it controls the separation efficiency in the distillation column. A higher reflux ratio improves separation, ensuring that cumin (isopropyl benzene) is concentrated at the top of the column.

What happens to the mixture after it passes through the reactor?

-After the reaction in the reactor, the mixture enters a separator where the desired products are separated. The remaining streams are then processed further through distillation columns to purify cumin and remove by-products.

What temperature is used during the reaction and why?

-The reaction temperature is maintained at 315°C, as it is optimal for the alkylation reaction to occur efficiently in the PFR reactor.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Benzena dan Turunannya • Part 1: Struktur, Sifat, Kegunaan, dan Pembuatan Benzena

Benzena dan Turunannya • Part 3: Lanjutan Soal Tatanama Senyawa Turunan Benzena

Kelas XII... Part.3 BENZENA DAN TURUNANNYA

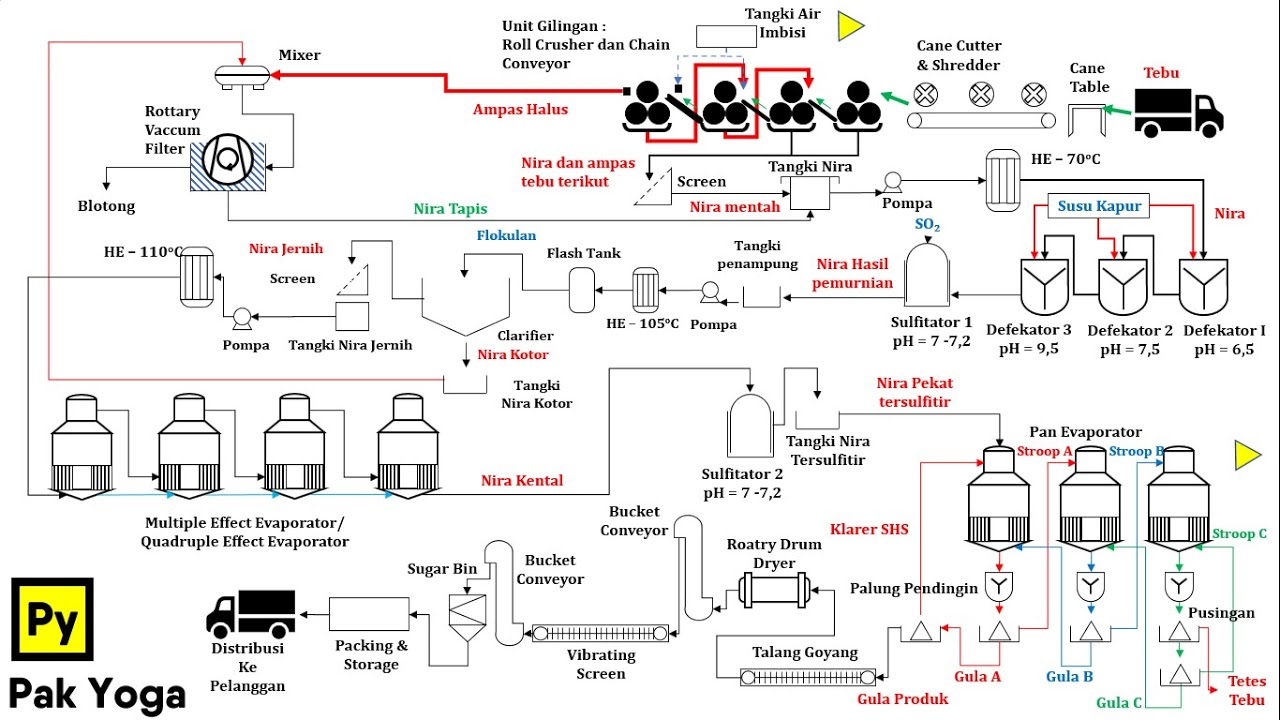

Kimia Industri - Diagram Alir Proses Pembuatan Gula tebu

Kesetimbangan kimia dalam industri (Nonuna)

Benzena dan Turunannya • Part 2: Tatanama Senyawa Turunan Benzena Orto Meta Para

5.0 / 5 (0 votes)