Mechanics of Materials - 2D Plane stress transformation equations

Summary

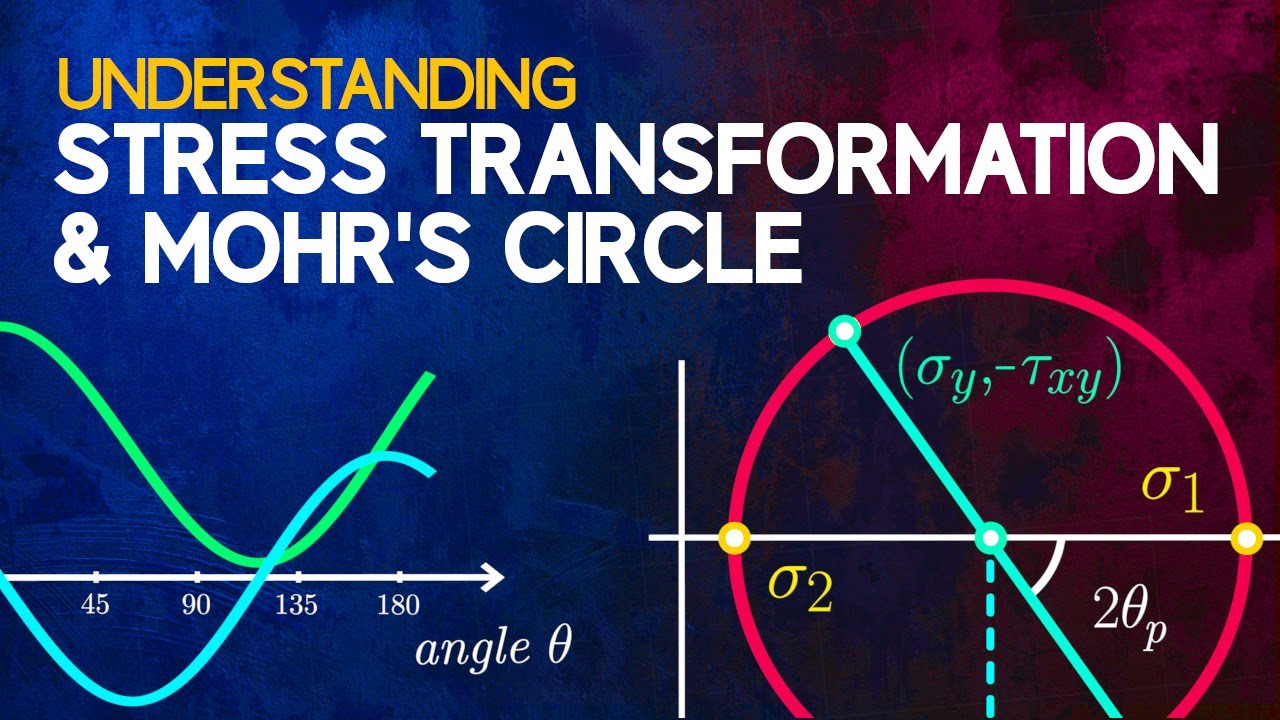

TLDRThis lecture explores the concepts of 2D plane stress and stress transformation in materials. It introduces the three main types of stress: normal stress in the x and y directions (σx, σy) and shear stress (τxy). The focus is on transforming these stresses when an element is rotated, with detailed equations provided to calculate the transformed stresses at a new orientation. The lecturer emphasizes sign conventions, rotation directions (counterclockwise as positive), and the importance of correctly applying stress values. This method is key to analyzing stresses in materials subjected to different loading conditions, including practical applications like wood or metal analysis.

Takeaways

- 😀 The concept of 2D stress transformation involves understanding how stresses change when a material's coordinate system is rotated.

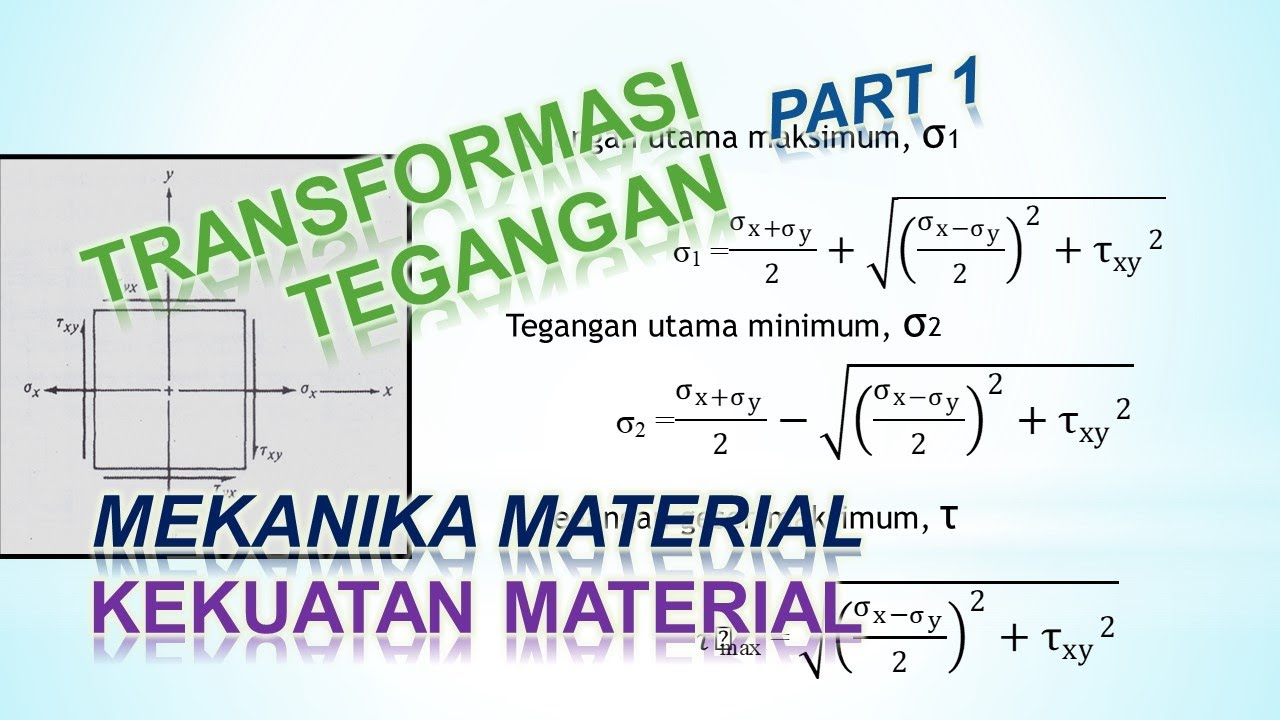

- 😀 In 2D, there are three main types of stresses: normal stress in the X direction (σx), normal stress in the Y direction (σy), and shear stress in the XY plane (τxy).

- 😀 Tension is considered positive for normal stresses, while compression is negative. Shear stress is positive when directed into the top-right corner of the element.

- 😀 The stresses in the material will change when the orientation of the coordinate system is rotated, even if the material’s internal forces remain unchanged.

- 😀 The transformation equations for normal and shear stress at a rotated coordinate system are: σx' = (σx + σy)/2 + ((σx - σy)/2) * cos(2θ) + τxy * sin(2θ) and τxy' = -(σx - σy)/2 * sin(2θ) + τxy * cos(2θ).

- 😀 When rotating the coordinate system, the angle θ is measured counterclockwise for positive rotations and clockwise for negative rotations.

- 😀 The shear stress (τxy) is directional and must be correctly represented as positive or negative depending on the orientation of the stress.

- 😀 The formula sheet provides the key equations for transforming stresses, which can be directly applied by substituting the values of σx, σy, τxy, and θ.

- 😀 To find the stress components at a different angle, you can either plug in θ + 90° or θ - 90° depending on which face of the element you are interested in.

- 😀 Caution must be taken with sign conventions, especially when dealing with compression (negative stress) and shear stress direction (negative when opposite the positive corner).

Q & A

What is meant by '2D plane stress'?

-2D plane stress refers to the stress state in a two-dimensional object, where stresses are analyzed in a specific plane. It typically involves normal stresses (Sigma X and Sigma Y) and shear stress (Tau XY) acting on an infinitesimally small square element within that plane.

What are the three types of stresses in a 2D stress state?

-The three types of stresses are: Sigma X (normal stress in the X direction), Sigma Y (normal stress in the Y direction), and Tau XY (shear stress in the XY plane).

How is tension defined in the context of 2D stress?

-In 2D stress analysis, tension is considered positive, meaning that if the stress is pulling away from the material or trying to elongate it, it is positive. Compression is negative, meaning the stress is compressing or squeezing the material.

What happens to the stress values when you rotate the element in a 2D stress analysis?

-When you rotate the coordinate system or cut the material at a different angle, the stress values (Sigma X, Sigma Y, Tau XY) change. The new stresses depend on the angle of rotation and can be calculated using specific transformation equations.

What are the transformation equations for Sigma X' and Tau XY'?

-The transformation equations for the new stresses are: Sigma X' = (Sigma X + Sigma Y) / 2 + (Sigma X - Sigma Y) / 2 * cos(2θ) + Tau XY * sin(2θ) and Tau XY' = (Sigma X - Sigma Y) / 2 * sin(2θ) + Tau XY * cos(2θ), where θ is the angle of rotation.

What is the significance of the angle θ in stress transformation?

-The angle θ represents the orientation of the new coordinate system relative to the original one. It determines how the stress components (Sigma X, Sigma Y, and Tau XY) will change when the material is rotated or cut at a different angle.

What does the term 'shear stress' refer to in this context?

-Shear stress (Tau XY) refers to the stress that acts parallel to the plane of interest. It causes one layer of the material to slide over another and can be positive or negative depending on the direction of the force.

How does the sign convention affect the stress calculations?

-The sign convention is crucial for correctly calculating stresses. Positive tension stresses are considered positive, while compression is negative. Shear stress is positive if it acts toward the top-right corner of the element, and negative if it acts toward the bottom-left corner.

What is the role of the formula sheet in stress transformation?

-The formula sheet provides the necessary equations for stress transformation. These equations allow the user to compute the new stress components (Sigma X', Sigma Y', Tau XY') based on the original stress values and the angle of rotation, without needing to memorize them.

What should you be cautious about when plugging values into the stress transformation equations?

-You must be careful with the signs of the stresses (whether they are positive or negative) and ensure that the correct angle (θ) is used. Incorrect signs can lead to errors in the transformation results.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahora5.0 / 5 (0 votes)