Fatal Exposure: Tragedy at DuPont

Summary

TLDRIn January 2010, a series of safety failures at DuPont's Belle, West Virginia plant led to three chemical releases, including a fatal exposure to phosgene, a toxic gas. Despite DuPont's strong safety culture, poor maintenance practices, ignored near-misses, and unsafe equipment management resulted in these preventable incidents. The Chemical Safety Board (CSB) investigated and found significant gaps in safety protocols, such as inadequate maintenance of hoses and lack of a phosgene enclosure. The CSB recommended stricter safety measures and improved near-miss reporting to prevent future tragedies. The video emphasizes the importance of proactive safety practices in high-risk industries.

Takeaways

- 😀 DuPont, founded in 1802, started as a gunpowder manufacturer and later became a global leader in chemical manufacturing, employing 58,000 people across 80 countries.

- 😀 DuPont had a strong safety reputation built on preventing accidents, particularly in explosive production, and aimed for zero injuries through improved safety practices.

- 😀 In January 2010, DuPont's safety record was questioned after three separate incidents at its Belle, West Virginia facility occurred within 33 hours, one of which was fatal.

- 😀 The first incident involved a five-day-long unnoticed release of methyl chloride, a hazardous gas, totaling 2,000 pounds of the chemical released inside the facility.

- 😀 The second incident was a release of oleum, a highly corrosive chemical, which resulted from corroded piping that was not properly inspected as recommended by DuPont's own safety guidelines.

- 😀 The third and most tragic incident was the fatal release of phosgene, a deadly chemical used as a pesticide intermediate, after a hose failure during cylinder switching.

- 😀 Phosgene is highly toxic and can cause severe damage to lungs, with symptoms potentially appearing hours after exposure. It is so dangerous that it was used as a chemical weapon in World War I.

- 😀 The phosgene hose failure occurred because the hoses, made from stainless steel lined with PTFE, were not replaced in over seven months, exceeding their recommended service life of 30 days.

- 😀 Despite recommendations in the 1980s, DuPont did not use more durable hoses made from Monel, a material that could withstand the corrosion and pressure of phosgene use, which could have prevented the incident.

- 😀 The CSB (Chemical Safety Board) recommended that DuPont implement better safety measures, such as installing enclosures with ventilation systems, secondary containment for toxic gases, and improving maintenance protocols to avoid similar incidents in the future.

Q & A

What was the initial focus of DuPont when it was founded in 1802?

-DuPont was initially founded as a gunpowder manufacturer in 1802.

How did DuPont's safety reputation get affected in January 2010?

-DuPont's safety reputation was shaken when three separate accidents occurred within 33 hours at its Belle, West Virginia plant, including a fatal release of phosgene.

What was the cause of the first incident at DuPont's Belle plant on January 17, 2010?

-The first incident involved the release of methyl chloride due to an open rupture disk and an improperly located drain hole, which went unnoticed for five days.

What chemical was released during the second incident on January 23, 2010?

-The second incident involved the release of oleum, a concentrated form of sulfuric acid, caused by corroded piping in the spent-acid recovery unit.

What was the third and most fatal incident at the Belle plant in January 2010?

-The third incident was the fatal release of phosgene, a highly toxic gas, which resulted in the death of one worker and exposed others to the toxic substance.

Why was the phosgene hose failure at the Belle plant particularly dangerous?

-The PTFE-lined stainless steel hoses used for phosgene were permeable, allowing phosgene to seep through and corrode the stainless steel, which increased the risk of failure and dangerous leaks.

What critical maintenance procedure was ignored at DuPont's Belle plant, leading to the fatal incident?

-DuPont failed to replace the phosgene hoses, which were supposed to be changed every 30 days. The hoses had not been replaced in over seven months, and the plant's maintenance software no longer notified operators when it was time to do so.

What safety recommendations did DuPont ignore that could have prevented the phosgene release?

-DuPont ignored a recommendation from 1987 to replace the braided stainless steel hoses with more durable Monel hoses. They also did not implement a safer enclosure for the phosgene operation, which was suggested in 1988 and again in 2004.

What were some of the CSB's recommendations for improving safety at DuPont's Belle plant?

-The CSB recommended improvements such as secondary enclosures, mechanical ventilation, emergency scrubbers, and automated audible alarms for phosgene units. They also suggested updating near-miss reporting policies and increasing anonymous participation from workers.

What role did the near-miss events play in the accidents at DuPont's Belle plant?

-The near-miss events, such as the previous phosgene hose failure, were warning signs that were not acted upon. The CSB found that DuPont's failure to address these early warnings contributed to the escalation of the accidents.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

Hot Work: Hidden Hazards

Seismic Seconds - The Bhopal Gas Disaster Part 1 of 3

Disastro di Seveso, uno degli incidenti ambientali più grandi d'Italia: cos'è accaduto e perché

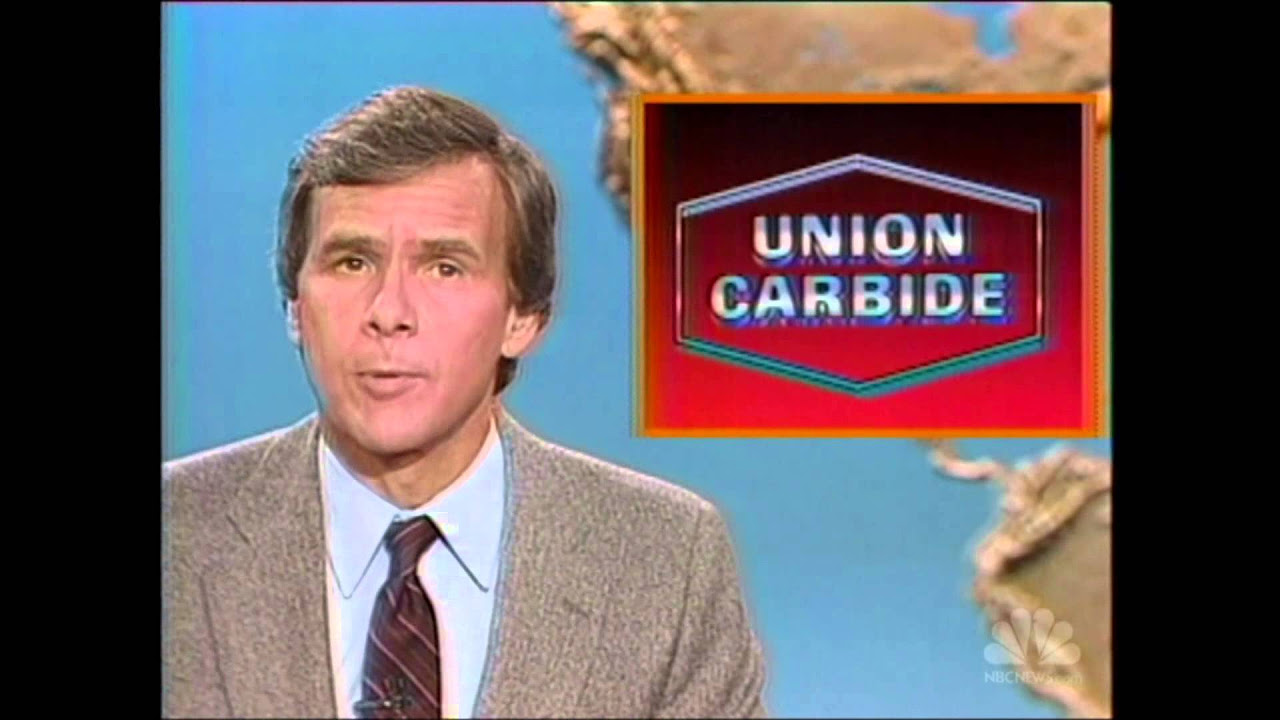

Union Carbide Disaster In Bhopal India | Flashback | NBC News

No Detection: Explosion at Watson Grinding

Bhopal Gas Tragedy | Who was Responsible? | Dhruv Rathee

5.0 / 5 (0 votes)