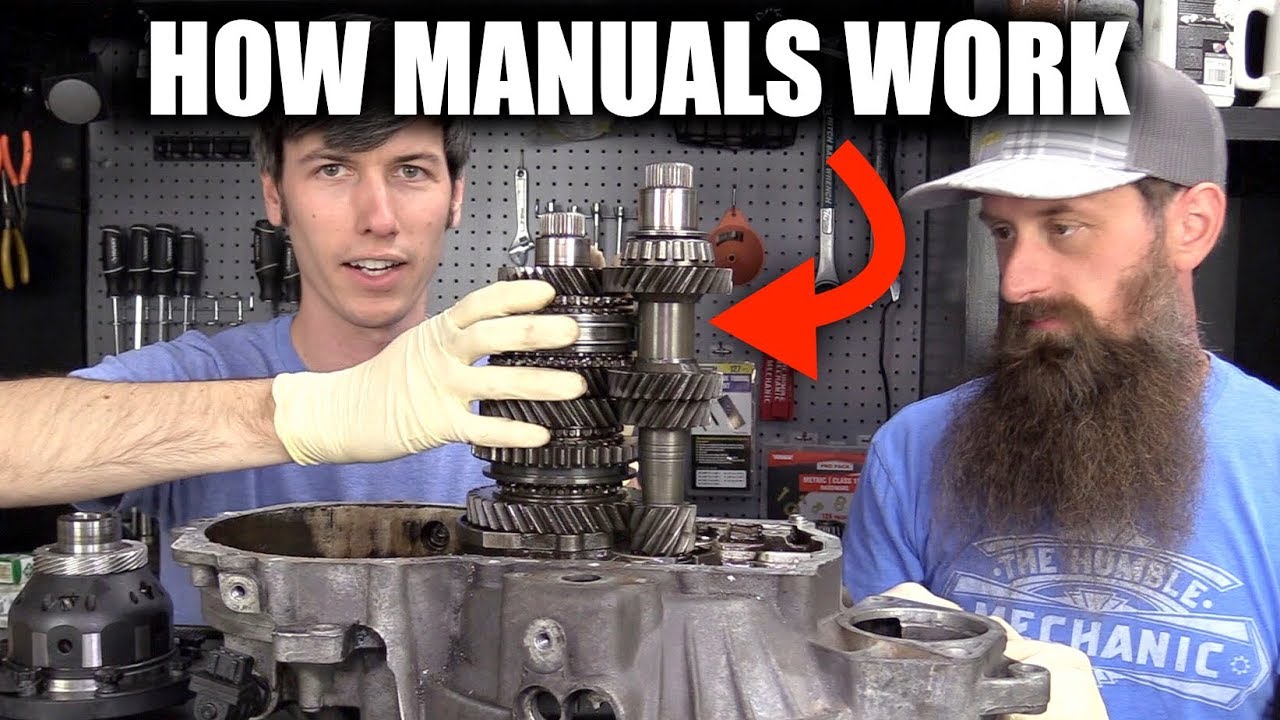

How does a driveshaft work? What is a CV joint? Automotive systems explained!

Summary

TLDRThis video explains the intricate workings of driveshafts in vehicles, highlighting their role in transmitting torque from the transmission to the wheels. It covers various types of driveshafts, their components, and how they accommodate suspension movements. The importance of universal joints and constant velocity joints is emphasized, detailing their construction and functionality in maintaining smooth operation and minimizing vibrations. By understanding these complexities, viewers gain insight into diagnosing and repairing driveline issues, showcasing the technical expertise required in automotive maintenance.

Takeaways

- 😀 Driveshafts transmit torque from the transmission to the wheels, making them crucial for vehicle operation.

- 🔧 Achieving reliable torque transmission requires overcoming complexities, including variations in angles and lengths due to suspension movement.

- ⚙️ Propeller shafts, used in rear-wheel, four-wheel, and all-wheel drive vehicles, can be made from materials like steel, aluminum alloy, or carbon fiber.

- 📏 Universal joints (U-joints) are vital for allowing torque to be transferred through angles, with the Cardan joint being the most common type requiring maintenance.

- 🔄 Velocity fluctuations occur during operation, affecting the smoothness of torque delivery, which can lead to vibrations if not managed properly.

- 🛠️ Phasing, or synchronizing U-joints, helps to cancel out velocity fluctuations and minimize vibrations during operation.

- 🚗 Constant velocity (CV) joints are ideal for front-wheel drive vehicles as they handle larger working angles without causing velocity fluctuations.

- 🔍 Outboard CV joints use ball bearings and require proper lubrication to function effectively and maintain performance.

- 🌪️ Slip joints are designed to accommodate changes in length during suspension travel, ensuring the driveshaft can adapt to movement.

- 💡 Understanding the complexities of driveshaft systems enhances technicians' ability to diagnose and repair related faults effectively.

Q & A

What is the primary function of a driveshaft in a vehicle?

-The primary function of a driveshaft is to transmit torque from the transmission to the final drive or directly to the wheels.

Why are there different types of driveshaft systems in vehicles?

-Different types of driveshaft systems are used to overcome complexities in delivering torque reliably and vibration-free, accommodating variations in angles and lengths due to suspension movement.

What materials are commonly used to construct propeller shafts?

-Propeller shafts are commonly constructed from steel, aluminum alloy, or carbon fiber, often designed in a tubular shape to minimize weight while maintaining strength.

How do universal joints (U-joints) function in a driveshaft?

-Universal joints allow torque to be transmitted through angles by permitting some rotational flexibility, enabling the driveshaft to adapt to the varying positions of the transmission and wheels.

What are velocity fluctuations, and why are they significant in driveshafts?

-Velocity fluctuations occur when a universal joint transmits driving torque through an angle, causing the output shaft's rotational speed to vary. If left uncontrolled, these fluctuations can lead to extreme vibrations throughout the vehicle.

What is phasing in relation to driveshafts, and how does it help minimize vibrations?

-Phasing refers to synchronizing the universal joints at either end of the driveshaft so that the velocity fluctuations produced cancel each other out, thus reducing vibrations during operation.

What is the role of slip joints in driveshaft systems?

-Slip joints allow the driveshaft to change its length in response to suspension travel, accommodating the distance changes between the transmission output shaft and the final drive assembly.

What are constant velocity (CV) joints, and where are they typically used?

-Constant velocity joints are used in vehicles with independent suspension systems because they can handle larger working angles without causing velocity fluctuations, thus improving steering ability.

How are outboard and inboard CV joints differentiated?

-Outboard CV joints allow for steering angles and typically contain ball bearings in a flexible rubber boot, while inboard CV joints allow for suspension travel without changing steering angles and are classified as plunging ball types.

What is the significance of the center bearing in long wheelbase rear-wheel drive vehicles?

-The center bearing minimizes driveline vibrations by converting a long driveshaft into two shorter shafts, thereby improving stability and performance at high rotational speeds.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

5.0 / 5 (0 votes)