What is the Automation Pyramid?

Summary

TLDRThis video explains the Automation Pyramid, a model that illustrates different levels of automation in industry. Starting at the field level, which includes sensors and actuators on the production floor, it moves up to the control level with PLCs and PIDs managing these devices. The supervisory level introduces SCADA for overseeing multiple systems, followed by the planning level using MES to monitor the entire production process. At the top is the management level, where ERP systems provide company-wide oversight. The video emphasizes how integrated technology boosts efficiency and transparency in industrial automation.

Takeaways

- 🔧 The automation pyramid is a visual representation of different levels of automation in a factory or industry.

- 🏭 The field level at the bottom consists of devices like actuators and sensors found on the production floor.

- ⚙️ The control level, which includes PLCs (Programmable Logic Controllers) and PIDs, manages the devices at the field level.

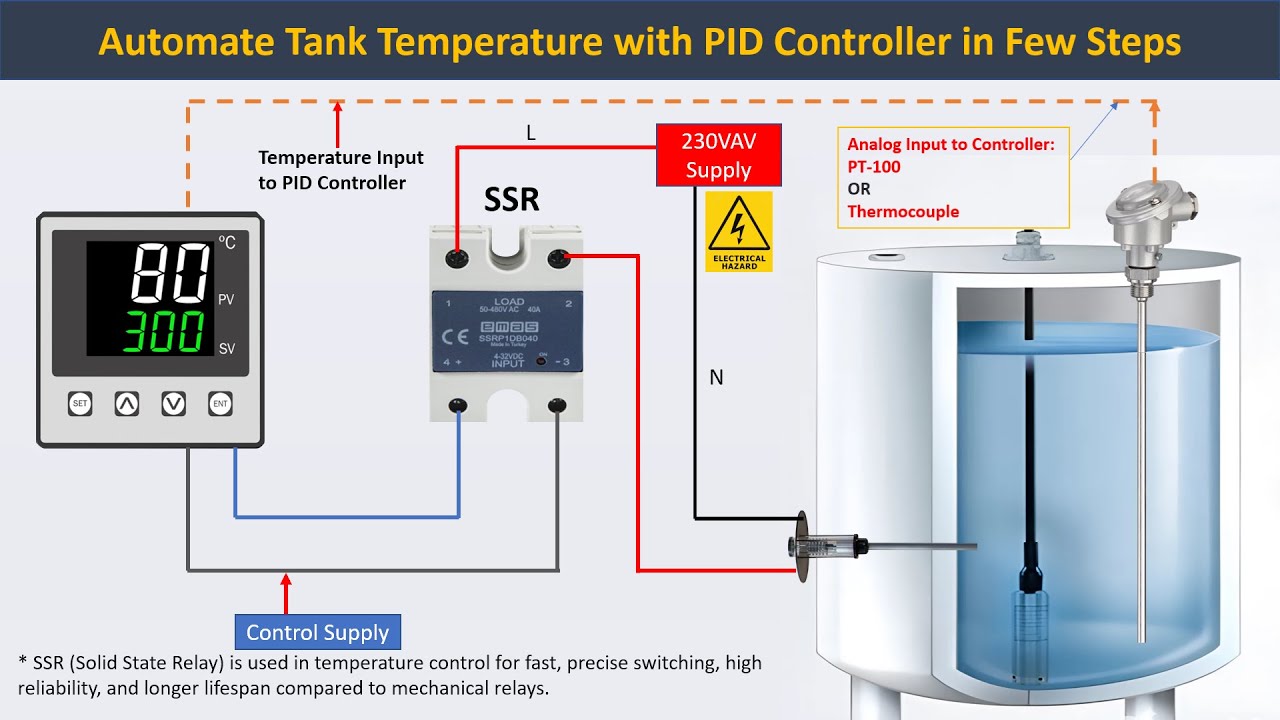

- 🚗 A PID is commonly used for control systems, such as cruise control in cars or heaters in industrial plants.

- 🖥️ The supervisory level uses SCADA (Supervisory Control and Data Acquisition) to control and monitor multiple systems remotely, often with a graphical user interface (HMI).

- 🌊 SCADA technology is often used in water plants to manage remote systems like pumps from a single location.

- 📊 The planning level is managed by MES (Manufacturing Execution System), which tracks the entire production process from raw materials to the final product.

- 📈 The top level, called the management level, utilizes ERP (Enterprise Resource Planning), allowing company leaders to monitor and manage overall operations.

- 🧑💼 ERP integrates all levels of a business, promoting efficiency and transparency by unifying various company departments.

- 🎓 RealPars offers comprehensive training in automation and controls engineering, including PLC programming, which can lead to highly sought-after jobs.

Q & A

What is the automation pyramid?

-The automation pyramid is a pictorial representation of the different levels of automation in a factory or industry. It shows how various technologies are integrated to manage and control industrial operations.

What devices are found at the 'field' level of the automation pyramid?

-At the 'field' level, devices include actuators, sensors, electric motors, hydraulic and pneumatic actuators, proximity switches, and photoelectric switches. These devices perform the physical work and monitoring on the production floor.

What is the role of the control level in the automation pyramid?

-The control level uses PLCs (Programmable Logic Controllers) and PIDs (Proportional–Integral–Derivative controllers) to control the devices at the field level. It processes information from sensors and other input devices to make decisions and manage outputs.

What is a PID, and how is it used in industrial automation?

-A PID is a Proportional–Integral–Derivative controller that maintains variables within a set of parameters. In industrial automation, PIDs are used to control systems like heaters by adjusting outputs to maintain a desired setpoint, such as temperature.

How does SCADA fit into the automation pyramid?

-SCADA (Supervisory Control and Data Acquisition) is used at the supervisory level of the automation pyramid. It monitors and controls multiple systems from a single location, often incorporating a graphical user interface (HMI) for remote control of operations.

What is the difference between SCADA and HMI?

-HMI (Human-Machine Interface) typically controls a single machine or system, while SCADA can monitor and control multiple systems across larger areas from a centralized location.

What is the role of the MES (Manufacturing Execution System) in the automation pyramid?

-MES operates at the planning level of the pyramid, monitoring the entire manufacturing process, from raw materials to finished products. It helps management make decisions based on real-time data from the factory floor.

What does the ERP system do at the top of the automation pyramid?

-The ERP (Enterprise Resource Planning) system is used by top management to monitor and control the entire business operation. It integrates data from different levels of the pyramid, including manufacturing, sales, finance, and other functions, promoting efficiency and transparency.

Can SCADA systems control systems over long distances?

-Yes, SCADA systems are designed to control and monitor operations over large areas and long distances, making them ideal for industries like water plants that require remote control of equipment.

How does the automation pyramid improve industrial operations?

-The automation pyramid improves efficiency by integrating different technologies at various levels, from the production floor to enterprise management. It allows for centralized control, real-time monitoring, data-driven decision-making, and improved transparency across the organization.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

ISTQB FOUNDATION 4.0 | Tutorial 49 | Test Pyramid | Testing Quadrants | Test Management | CTFL

Por que investir na AUTOMAÇÃO da sua OPERAÇÃO LOGÍSTICA?

Why AI Automation Agencies are Obviously The Next Big Thing

A Look At The "Test Automation" Pyramid

Technische Automatisering 1: Blokschema

PID Controller Tutorial for Beginners: Learn PID Loop Control & Tuning Basics

5.0 / 5 (0 votes)