Chapter 1 Quality Control Basics

Summary

TLDRThis chapter introduces Quality Control (QC) in medical laboratories, emphasizing its role in ensuring reliable patient test results through statistical monitoring. It outlines the necessity for regular QC product testing alongside patient samples and comparing these results to predefined statistical limits. The script explains the importance of using QC products, which mimic patient samples, to validate the performance of diagnostic instruments. It also discusses the significance of maintaining a QC database to assess the analytical process's stability, using examples like potassium levels to illustrate the concept of 'in control' and 'out of control' states, which are crucial for determining the reliability of test outcomes.

Takeaways

- 🔬 Quality Control (QC) in medical labs is a statistical process to monitor and evaluate the reliability of patient test results.

- 📊 The two requirements for QC are regular testing of QC products alongside patient samples and comparing results to statistical limits.

- 🧪 QC results are essential to validate if lab instruments are operating within specifications, ensuring patient results are reliable.

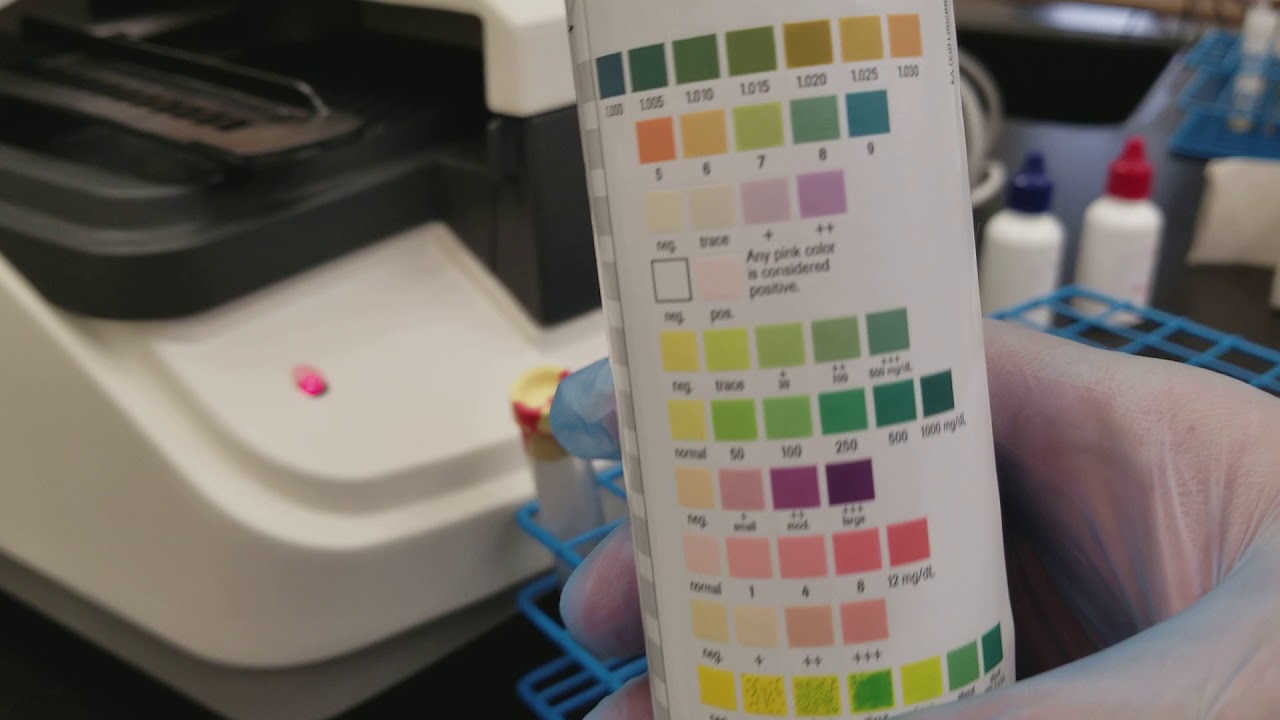

- 🩸 Test results can be quantitative, qualitative, or semi-quantitative, and QC results help confirm the accuracy of these measurements.

- 🧬 A quality control product should mimic patient samples, ideally made from human biological materials and containing known analyte concentrations.

- 🌡️ Normal and abnormal control products are tested daily to monitor the lab's analytical process, with normal controls reflecting typical values and abnormal controls showing values outside the normal range.

- 📈 A QC database is created by regular testing, which is used to validate the test system by comparing results to a lab-defined range of values.

- 🚫 If daily QC results fall outside the expected range, the lab is considered 'out of control,' and patient results from that day may be unreliable.

- ⏱️ The frequency of QC testing may need to be increased if a test is unstable for less than 24 hours or if changes occur that could affect test stability.

- 📉 An example provided is potassium levels, where normal ranges and abnormal ranges are defined, and daily QC results are compared against these to assess the lab's control status.

Q & A

What is Quality Control in the context of medical laboratories?

-Quality Control (QC) in medical laboratories is a statistical process used to monitor and evaluate the analytical process that produces patient results, ensuring the reliability of those results.

What are the two requirements for a statistical process in quality control?

-The two requirements are: 1) Regular testing of quality control products along with patient samples, and 2) Comparison of quality control results to specific statistical limits (ranges).

How do QC results validate the reliability of patient test results?

-QC results are used to check if the instrument is operating within pre-defined specifications, which infers that the patient test results are reliable.

What is the significance of the potassium test result in a patient's serum?

-The potassium test result indicates the concentration of potassium in the blood, which is used by physicians to determine if the patient has low, normal, or high potassium levels.

Why is it important to use quality control materials regularly?

-Regular use of quality control materials and statistical process control helps resolve the reliability of test results by ensuring the instrument is not out of calibration and the patient's true values are accurately measured.

What is a quality control product and how is it different from a patient sample?

-A quality control product is a patient-like material, ideally made from human serum, urine, or spinal fluid, with known concentrations of one or more constituents (analytes). It is tested in the same manner as patient samples but is used to monitor the analytical process rather than diagnose a patient.

What are the differences between normal and abnormal control products?

-A normal control product contains analytes at levels within the normal range, while an abnormal control product contains analytes at concentrations above or below the normal range.

Why is it necessary to test both normal and abnormal controls daily?

-Testing both normal and abnormal controls daily is a good laboratory practice to monitor the analytical process and ensure the reliability of patient test results.

What does it mean when the laboratory is 'in control' or 'out of control'?

-When daily QC results are within the expected range, the analytical process is 'in control', indicating reliable test results. When the results are outside the expected range, the laboratory is 'out of control', suggesting potential errors that may affect the reliability of patient results.

How is the acceptable range for quality control determined?

-The acceptable range for quality control is determined by comparing daily QC results to a laboratory-defined range of QC values, which is calculated from QC data collected from testing of normal and abnormal controls.

What should a laboratory do if it is 'out of control'?

-If a laboratory is 'out of control', it should not report any patient samples with results that are affected by the error until the issue is resolved and the affected samples are re-tested.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

5.0 / 5 (0 votes)