Telecurso 2000 - Manutenção - 15 Desmontagem

Summary

TLDRThis instructional video script focuses on the proper procedures for disassembling and maintaining machinery. It emphasizes the importance of following a sequence to avoid accidents and inefficiency, starting with disconnecting electrical circuits, removing external parts, and cleaning the machine. The script also highlights the use of desoxidants for rusted bolts and the correct order for loosening them, as well as the necessity of identifying component positions before removal. Finally, it touches on washing parts and categorizing them for reconditioning or replacement, setting the stage for a future lesson on reassembling mechanical sets.

Takeaways

- 🔧 The importance of following a proper sequence when disassembling machinery to facilitate work and prevent accidents.

- 🛠️ Disassembling equipment hastily can lead to wasted time and effort, as demonstrated by the character Caio who had to reassemble the entire machine to find the fault.

- 👷♂️ The necessity of understanding the problem before disassembling a machine, based on the operator's report, maintenance records, and control instrument tests.

- 💡 The process of disassembling should begin by disconnecting electrical circuits and removing external parts made of plastic, rubber, or leather to ensure safety.

- 🧼 Cleaning the machine before removing electrical circuits, levers, hoses, and tubes to prevent contamination and accidents.

- 🔩 The use of desoxidants on screws before removal to prevent them from being stuck due to oxidation, and the alternative method of using a welding torch if needed.

- 🔧 The order of unscrewing should follow the same sequence used when they were tightened, which can be found in a tightening sequence table.

- 📐 Identifying the position of components before removal is crucial for correct reassembly, even with manuals and sketches.

- 🚿 Washing parts with kerosene after disassembly is essential to reveal defects or wear, using a washing machine and stiff brushes.

- 🔬 After washing and drying, parts should be sorted into batches according to their condition: perfect, needing reconditioning, damaged to be replaced, or needing laboratory examination.

- 🔄 The script emphasizes the importance of a systematic approach to machine maintenance, including disassembly, cleaning, and sorting parts for further action.

Q & A

What is the main topic of the 15th teleclass in the professional course?

-The main topic of the 15th teleclass is the proper sequence and procedures for disassembling machinery and equipment.

Why did Caio make a mistake in the script?

-Caio made a mistake by disassembling the machine hastily without first identifying the cause of the malfunction, which resulted in wasted time and effort.

What is the importance of following the correct disassembly sequence?

-Following the correct disassembly sequence facilitates the work, prevents accidents, and ensures that the machine can be reassembled correctly.

What should be done before disassembling a machine?

-Before disassembling a machine, one should analyze the problem based on the operator's report, maintenance records, and conduct tests with control instruments to identify the malfunction.

What is the first step in the disassembly process according to the script?

-The first step in the disassembly process is to disconnect the electrical circuits to prevent accidental activation of the machine.

Why is it necessary to remove external parts made of plastic, rubber, or leather before cleaning the machine?

-Removing external parts made of plastic, rubber, or leather before cleaning helps to prevent contamination of important components during the preliminary cleaning of the machine.

What is the purpose of draining lubricants during the disassembly process?

-Draining lubricants prevents oil from spilling on the floor or workbench, which could cause accidents.

Why is it important to use desoxidants on screws before removing them?

-Desoxidants are used to break the oxidation binding on screws, making them easier to remove and preventing damage to the machine components.

What should be done if desoxidants are not enough to remove a screw?

-If desoxidants are not enough to remove a screw, one can use a oxy-acetylene welding torch to heat the screw, which will help loosen it.

How should screws be removed if they are stuck due to oxidation?

-If screws are stuck due to oxidation, they should be heated with an oxy-acetylene welding torch to loosen them before attempting to remove them.

What is the final step described in the script for the disassembly process?

-The final step described in the script for the disassembly process is to wash the parts with kerosene, dry them, and then separate them into different lots based on their condition.

Outlines

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraMindmap

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraKeywords

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraHighlights

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraTranscripts

Esta sección está disponible solo para usuarios con suscripción. Por favor, mejora tu plan para acceder a esta parte.

Mejorar ahoraVer Más Videos Relacionados

PERAWATAN TRAKEOSTOMI

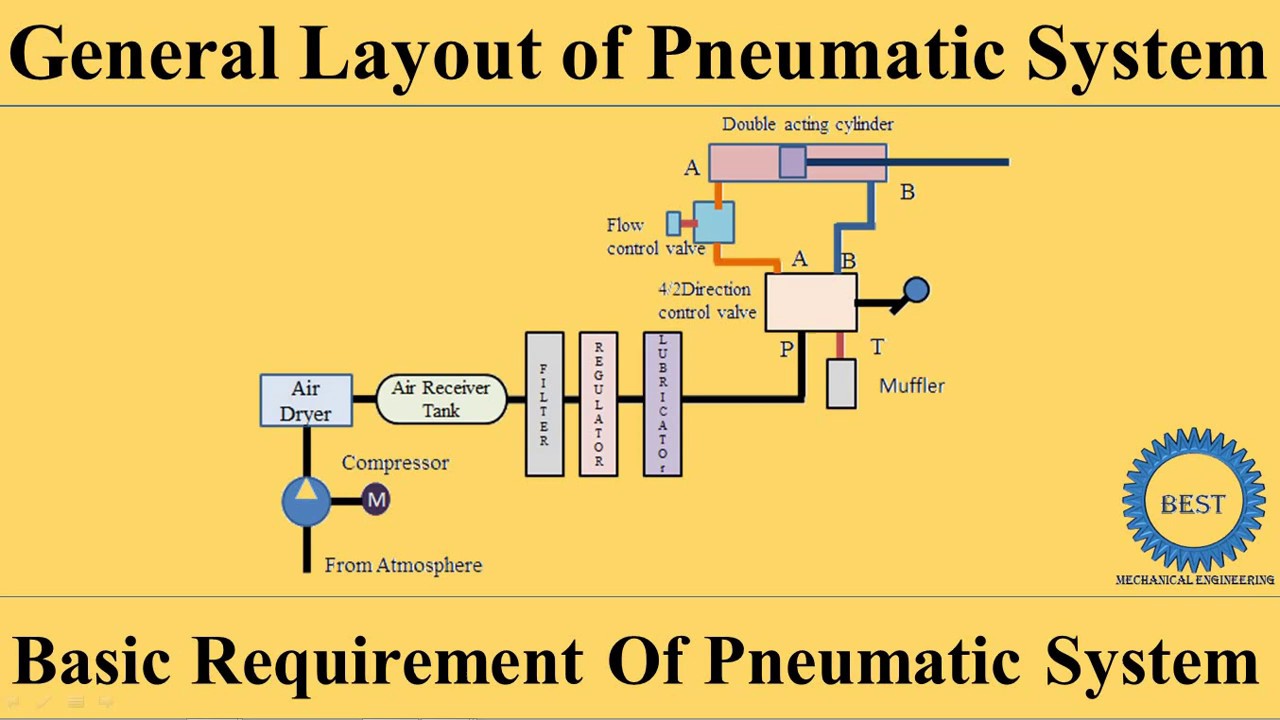

General Layout And Basic Requirement of Pneumatic System

Telecurso 2000 Manutenção 17 Recuperação de elementos mecânicos

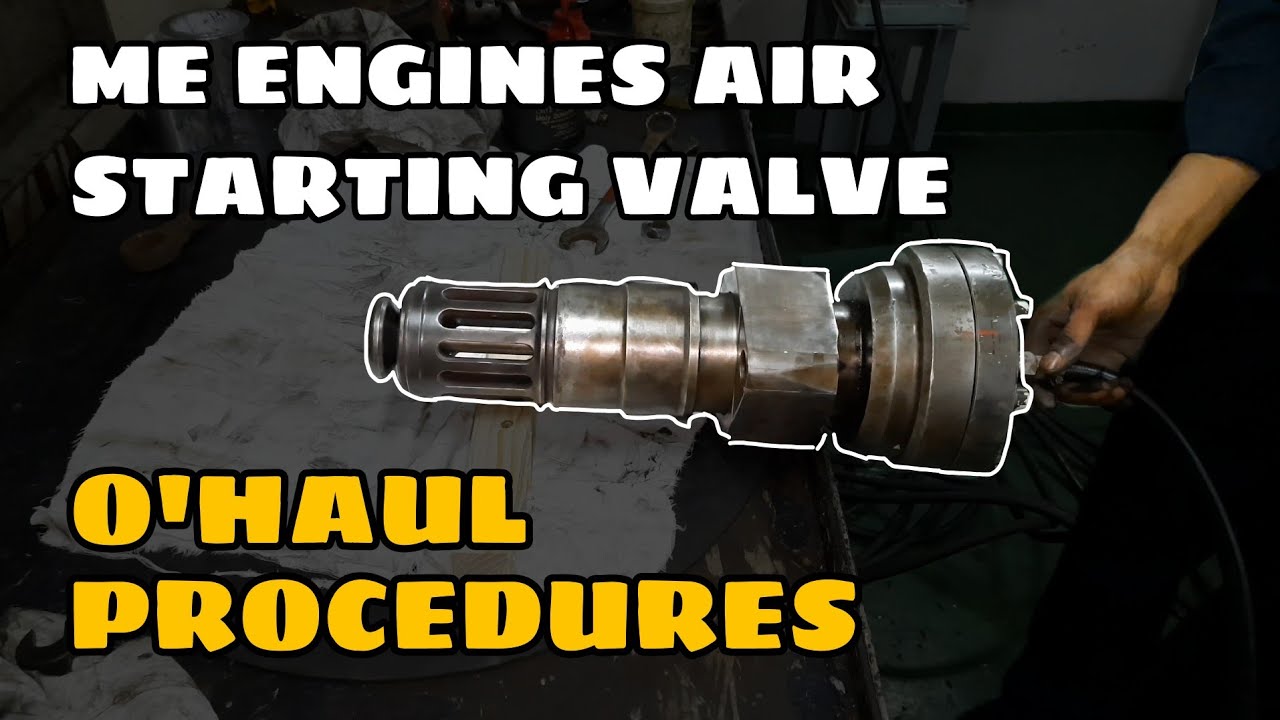

ME ENGINES AIR STARTING VALVE O'HAUL PROCEDURES

PPPK TECHNICAL QUESTION OUTLINE STAGE 2 OFFICE ADMINISTRATION COMPLETE WITH DISCUSSION AND QUESTIONS

Belt & Disc Sander (Metal Shop Machinery)

5.0 / 5 (0 votes)