Part 1: Introduction to Testing Battery Management System (BMS) Software

Summary

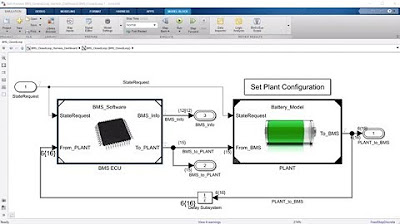

TLDRIn this video, MathWorks' engineers Francesco Alderisio and Maurizio Dalbard introduce methods and techniques for verifying, validating, and testing Battery Management System (BMS) requirements using Simulink. They demonstrate the model-based design process, emphasizing the importance of early validation to catch errors efficiently. The session covers the system analysis, including the plant components and the BMS ECU, and highlights the role of Stateflow in implementing state machines for different operational modes. The presentation also touches on the Model-Based Design workflow's benefits, including its ability to meet stringent certification standards like ISO 26262 for automotive software development.

Takeaways

- 🔧 Francesco Alderisio and Maurizio Dalbard from MathWorks are presenting methods and techniques for verifying, validating, and testing BMS requirements using Simulink before software deployment.

- 🛠️ The system analysis includes a controller, plant components like a battery pack, recharge circuit, and charger/load, with physical connections and electrical components highlighted.

- 🔌 The pre-charge circuit has six switching devices that need to be controlled to prevent electrical spikes.

- 🔋 The battery pack model includes six cells in series and thermal behavior via convection, along with a cell monitoring unit for charge balancing.

- 🤖 The BMS ECU model comprises different components for tasks like balancing logic, SOC estimation, and a state machine implemented in Stateflow.

- 🔄 The state machine includes parallel states for standby, charging, driving modes, fault monitoring, and contactor control to prevent spikes.

- 🔍 The Model-Based Design workflow is emphasized for early identification of errors, with a shift from ambiguous designs to graphical models for precise software specification.

- 📈 The cost of finding bugs increases over time, making early validation in the design process crucial for cost-effectiveness.

- 🛑 Simulation is an early validation tool, but a more rigorous approach is needed for systematic testing to ensure all requirements are met.

- 📚 The complete Model-Based Design process allows for earlier and more cost-effective error identification, with simulation and testing integrated into the workflow.

- 🏢 Companies like LG have used this workflow to develop BMS software for hybrid vehicles, achieving ISO 26262 SLC certification for AUTOSAR code.

- 📘 The Model-Based Design workflow is part of a development process approved by TUV certification authority, with documentation included in the IEC Certification Kit and DO Qualification Kit.

Q & A

What is the role of Francesco Alderisio in the presentation?

-Francesco Alderisio is an application engineer at MathWorks, and he is the presenter who introduces the topic of verifying, validating, and testing BMS (Battery Management System) requirements using Simulink.

Who is Maurizio Dalbard and what does he contribute to the presentation?

-Maurizio Dalbard is a Senior Application Engineer at MathWorks. He provides an overview of the Model-Based Design workflow, focusing on verification and validation, and discusses the importance of systematic testing in the development process.

What is the purpose of the system analysis presented in the script?

-The system analysis is aimed at understanding the components and connections within a BMS, including the controller, plant, battery pack, recharge circuit, charger, and load, to ensure proper control and avoid undesired electrical spikes.

What are the different components of the plant mentioned in the script?

-The plant consists of a battery pack, a recharge circuit, and a charger and load setup, each with specific components such as switching devices and thermal behavior models.

How many cells are connected in series in the battery pack model?

-In the battery pack model, there are six different cells connected in series.

What is the role of the cell monitoring unit in the BMS?

-The cell monitoring unit is responsible for controlling other switching devices to maintain a balanced state of charge across the different cells in the battery pack.

What are the four different model references mentioned in the BMS ECU?

-The four model references in the BMS ECU include a balancing logic, an SOC (State of Charge) estimation model, a state machine implemented in Stateflow, and fault monitoring states.

What is the significance of the state machine in the BMS ECU?

-The state machine in the BMS ECU is crucial as it implements logic to manage different states such as standby, charging, driving modes, and fault modes, ensuring the system operates correctly under various conditions.

What are the advantages of using Simulink for verifying and validating BMS requirements?

-Simulink allows for the use of graphical models or executable specifications that provide precise meanings, making it easier to identify errors early in the design phase, reducing the cost and complexity of bug detection.

How does the Model-Based Design process help in reducing the cost of finding bugs?

-The Model-Based Design process enables early validation of the design through simulation, which is more cost-effective than testing in the final phase, as errors are cheaper and easier to identify early on.

What is the significance of the IEC Certification Kit and DO Qualification Kit mentioned in the script?

-The IEC Certification Kit and DO Qualification Kit provide complete documentation for the Model-Based Design workflow, which is essential for developing critical embedded software that meets the standards required for certification by authorities such as TUV.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Battery Management System Development in Simulink

Indicators of all types of BMS - BMS 1S - 999S - BMS indicators

Kebutuhan Fungsional dan Non Fungsional

Testing dan Implementasi Sistem Informasi #Presentasi2

BMS (Battery Management System) || DIY or Buy || Properly protecting Li-Ion/Li-Po Battery Packs

BYD Atto 3 battery dismantle P1

5.0 / 5 (0 votes)