Labyrinth Seal

Summary

TLDRThe video script explains the function of a labyrinth seal in various mechanical systems, particularly in engine bearings and turbine interstages. It describes how the seal, composed of fins or knife edges, maintains oil tightness by utilizing pressure differences to prevent oil mist leakage. The script also covers the importance of equal oil distribution to each jet and the necessity of a larger scavenge system to handle the aerated, expanded oil resulting from the labyrinth seal's operation.

Takeaways

- 🔧 A labyrinth seal is made up of a series of fins or knife edges that create a minimum clearance with the lining upon initial engine operation.

- 💨 Pressurized air from the bleed air system is used to create a pressure drop across the fins, establishing a high-pressure and a low-pressure area.

- 🌫️ The oil mist created by the interaction between the oil and the hot bearing is prevented from seeping out due to the pressure differential, keeping the compartment oil-tight.

- 🛠️ The labyrinth seal is not airtight, allowing air to pass but preventing oil leakage, which is crucial for the operation of the engine.

- 📏 The scavenge system must have a larger capacity than the pressure system to handle the increased volume of aerated, warm oil.

- 🔄 The venting of compartments ensures equal pressure distribution, which is necessary for equal oil supply to each jet.

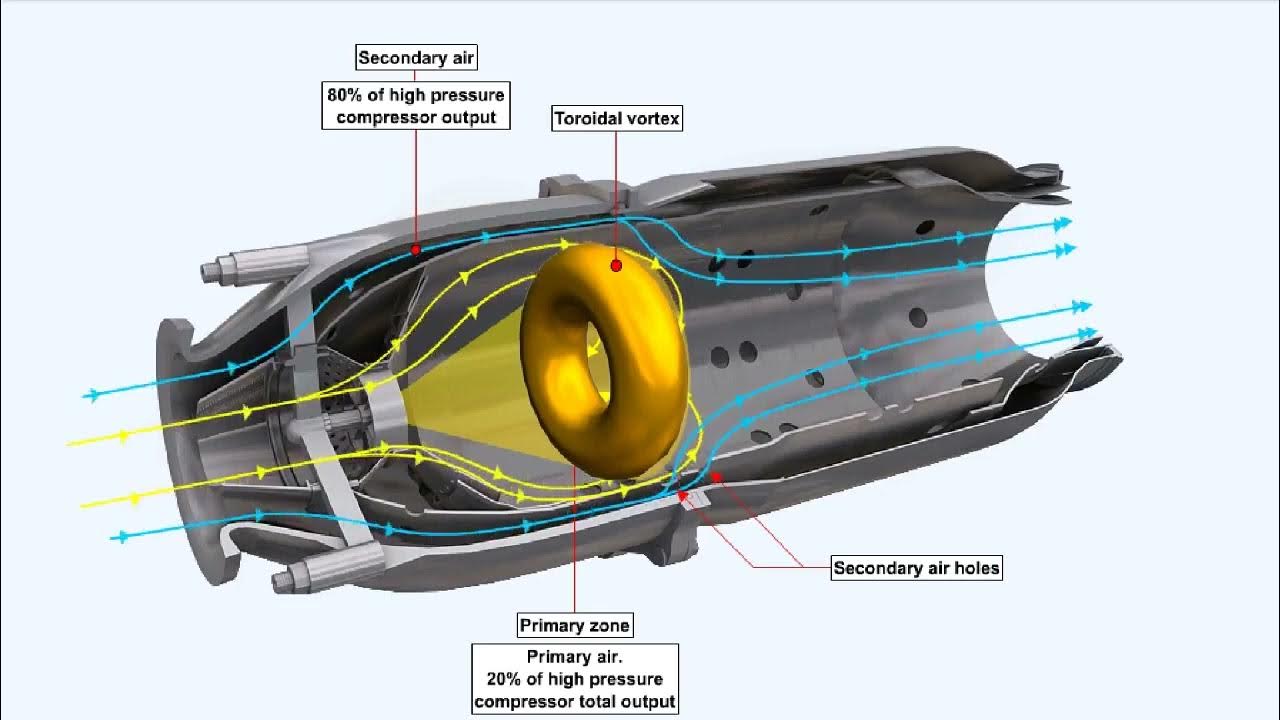

- 🛡️ The labyrinth seal is also used in interstage applications, such as in turbine areas, to prevent hot gases from reaching the bearings.

- 🌡️ The seal helps to manage temperature by creating a pressure gradient that directs gases away from sensitive components.

- 🔄 The design of the labyrinth seal involves a balance between maintaining oil tightness and allowing for air flow necessary for engine operation.

- 🛑 The seal's effectiveness relies on the precise interaction between the fins, the pressure system, and the scavenge system.

- 🔧 The labyrinth seal's knife edges are a critical component in maintaining the seal's functionality and preventing leakage.

Q & A

What is a labyrinth seal?

-A labyrinth seal is a type of mechanical seal that consists of a series of fins or knife edges designed to prevent leakage, typically used in rotating machinery such as engines or turbines.

How does a labyrinth seal function in an engine?

-In an engine, the labyrinth seal's fins lightly rub against the lining during initial running, cutting into it to create minimum clearance. Pressurized air from the bleed air system bleeds across the fins, creating a pressure drop that helps maintain oil tightness while allowing air to pass for cooling.

Why is oil mist created in the labyrinth seal?

-Oil mist is created when the oil sprayed onto the hot bearing from the pressure pump turns into mist due to the heat. The pressure difference created by the labyrinth seal causes the oil mist to stay within the compartment due to the natural tendency of gases to move from high to low pressure areas.

What is the purpose of the pressure drop in a labyrinth seal?

-The pressure drop in a labyrinth seal helps to maintain an oil-tight environment by creating a low-pressure area that prevents the oil mist from seeping out past the seal, while still allowing air to flow for cooling purposes.

How does the oil get warmed and expand in the labyrinth seal?

-The oil gets warmed when it hits the hot bearing, causing it to expand. This warm, expanded oil then moves to the bottom of the compartment, where it mixes with the air that has leaked past the seal, creating aerated oil.

Why is the scavenge system capacity larger than the pressure system?

-The scavenge system capacity must be larger to handle the increased volume of aerated oil, which can be up to three times the volume of the pressurized oil due to the expansion from heat and the mixing with air.

What is the role of vents in the labyrinth seal compartments?

-Vents in the labyrinth seal compartments ensure equal pressure between different compartments, which is important for distributing oil evenly to each of the jets or bearing areas.

How does an interstage seal in a turbine work?

-An interstage seal in a turbine works by using the pressure drop created by bleed air passing across the seal edges to prevent hot gases from leaking towards the bearings. The adverse pressure gradient discourages the gases from moving from a low-pressure to a high-pressure area.

Why is it important to keep hot gases away from the bearings in a turbine?

-Keeping hot gases away from the bearings is crucial to prevent overheating and potential damage to the bearings, as the hot gases from combustion can be very warm and may affect the performance and longevity of the machinery.

What are some applications of labyrinth seals other than in bearing compartments?

-Labyrinth seals can be used in various applications where leakage prevention is required. One such application is in interstage seals within turbines, where they help to prevent hot gases from reaching sensitive components.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

The Science Of Small Distances

08 ATPL Training Gas Turbine Engines 08 Combustion Chambers Part 1 720 X 1280

lesson 1: steam turbine operation and control with mechanical governor

Aircraft Gas Turbine Engines #03 - Introduction Part 3

Gear Forces and Power Transmission of SPUR GEARS in Just Over 12 Minutes!

How do ball and roller bearings work? Types and durability calculation. DIN ISO 281

5.0 / 5 (0 votes)