Recording 20241125 061617

Summary

TLDRIn this video, the instructor guides students through the process of conducting sampling analysis, focusing on acceptance probabilities and risks for producers and consumers. The session covers key concepts such as Quality Acceptance Limits (EQL), inspection levels, and how to calculate producer and consumer risks using Excel and Poisson distribution. Through a practical case study, the video walks through the steps of determining sampling plans (SSP and DSP), identifying defects, and understanding the distribution of defective items. Students are encouraged to apply these methods for better understanding of risk management in production processes.

Takeaways

- 😀 The video explains the analysis of a sampling plan, focusing on the acceptance probability and the risks to both producers and consumers.

- 😀 The goal is to teach how to assess sampling plans using examples and case studies, dividing the content into multiple videos for better understanding.

- 😀 The video begins with an explanation of terms like EQL (Expected Quality Level) and tolerance, highlighting the maximum defect percentage acceptable by the company.

- 😀 Key values provided in the example include an EQL of 10%, a load size of 600 products, inspection level 4, and inspection cost per item of Rp5,000.

- 😀 Risks related to product returns are important to consider in the sampling analysis, and return costs per item are also factored into the calculations.

- 😀 The video covers how to determine the sampling plan (SSP and DSP) using standard tables and inspection levels, referring to ISO standards for proper implementation.

- 😀 The sampling plan involves identifying sample sizes and acceptance criteria based on ISO tables (e.g., SSP: 20 samples, DSP: 13 samples for the given case).

- 😀 Probability calculations and risk assessments for both producers and consumers are key components of this video, with an emphasis on practical use of Excel for these computations.

- 😀 The Poisson distribution is recommended for calculating probabilities related to defective items because it is flexible for both defect counts and defect rates.

- 😀 The producer's risk refers to rejecting a batch with good items, leading to unnecessary delays or rejections, whereas the consumer's risk involves accepting a batch with too many defects.

- 😀 The video concludes with the practical application of these concepts in Excel, focusing on calculating acceptance probabilities using the Poisson distribution and determining the associated risks.

Q & A

What is the purpose of the video series mentioned in the script?

-The video series aims to help students understand sampling plans and analyze various risks associated with producers and consumers, with a focus on hands-on practical applications like determining acceptance and producer risks using statistical tools.

What are the key elements in the sampling plan discussed in the video?

-The key elements include the acceptable quality level (EQL), the sample size, inspection levels, inspection costs, and the return cost for defective products. These factors help determine the sampling plan and associated risks.

What is EQL, and how does it affect the sampling plan?

-EQL stands for 'acceptable quality level' and is defined as the percentage of defective items that can be tolerated by the company. In this case, it is 10%. It affects the sampling plan by guiding the calculation of the sample size and the assessment of risks, such as producer and consumer risks.

What are the special inspection levels mentioned in the video?

-Special inspection levels are classifications that define the rigor of an inspection process. In this video, Level 4 of the special inspection is mentioned, which dictates the sampling and inspection procedures to be followed.

What is the importance of the Poisson distribution in this context?

-The Poisson distribution is important for calculating the probabilities of defects occurring in a batch of products. It is used because it is flexible and can handle both defect items and defective products, which makes it suitable for analyzing acceptance and risks in this context.

What does the term 'producer's risk' refer to in the script?

-Producer's risk refers to the risk that a good lot of products will be rejected based on the inspection process, leading to potential losses because some acceptable products may not be shipped to consumers due to an incorrect rejection decision.

How are sample sizes determined for SSP and DSP in the video?

-Sample sizes are determined using specific tables from ISO standards. For SSP, a sample size of 20 is used, while for DSP, a sample size of 13 is used. These sizes are based on the lot size and the inspection level.

What role does Excel play in the calculation of acceptance probabilities and risks?

-Excel is used to apply statistical formulas, such as the Poisson distribution, to calculate the probability of acceptance and the producer's risk. The software helps in applying complex formulas efficiently, ensuring accurate results in the analysis.

What does the term 'consumer's risk' mean in this context?

-Consumer's risk refers to the chance that a defective lot, which should have been rejected, is accepted and shipped to the consumer. This risk highlights the possibility of a defective product being delivered to the customer.

How is the 'mu' (mean) calculated in the Poisson distribution?

-'Mu' (μ) is calculated as the product of the sample size (N) and the proportion of defective items (P), which is the EQL. For example, if the sample size is 20 and the EQL is 10%, then μ = 20 * 0.10 = 2.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Recording 20241125 061617

Simple Random Sampling | Contoh Acak Sederhana | contoh soal dan pembahasan

PENETAPAN KADAR LEMAK DENGAN METODE SOXHLET ( Analisis Kimia Pangan )

POBLACIÓN, MUESTRA Y MUESTREO

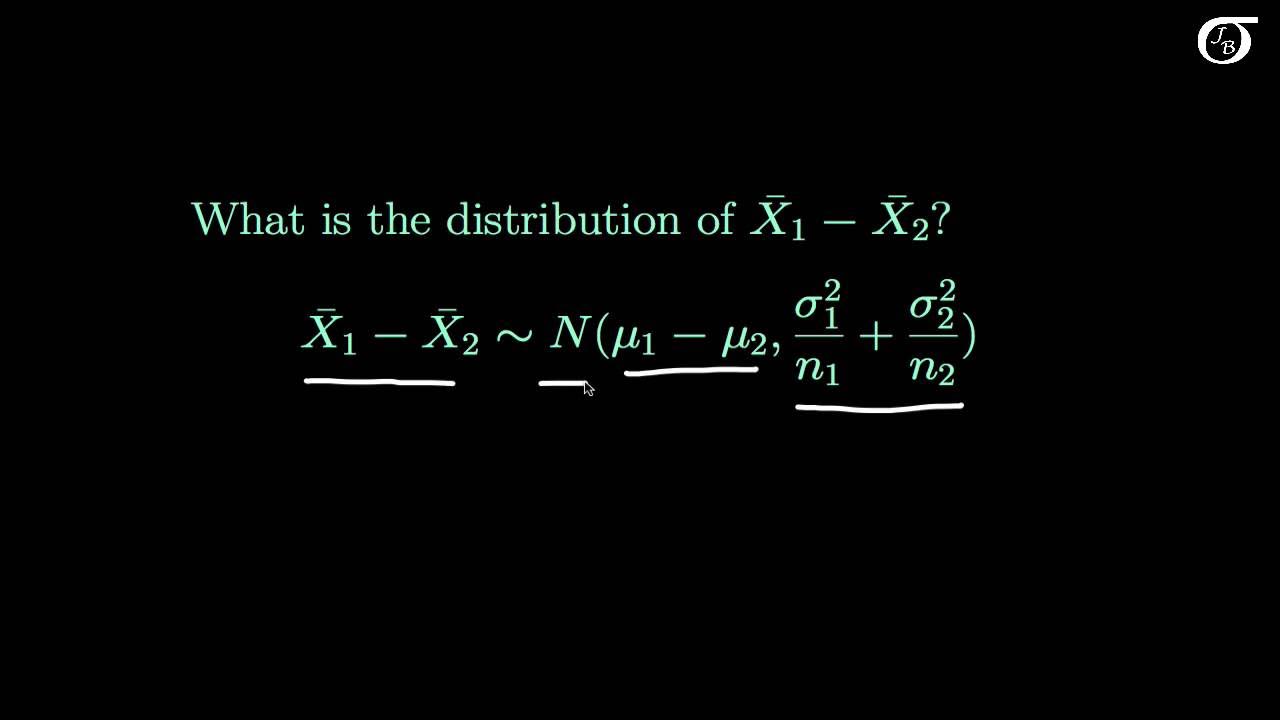

The Sampling Distribution of the Difference in Sample Means (X_1 bar - X_2 bar)

Matematika Kelas 8 Bab 6 Peluang - Frekuensi Relatif - hal. 174 - 175 - Kurikulum Merdeka

5.0 / 5 (0 votes)