Pengolahan Air PALYJA : IPA Pejompongan 1 & 2

Summary

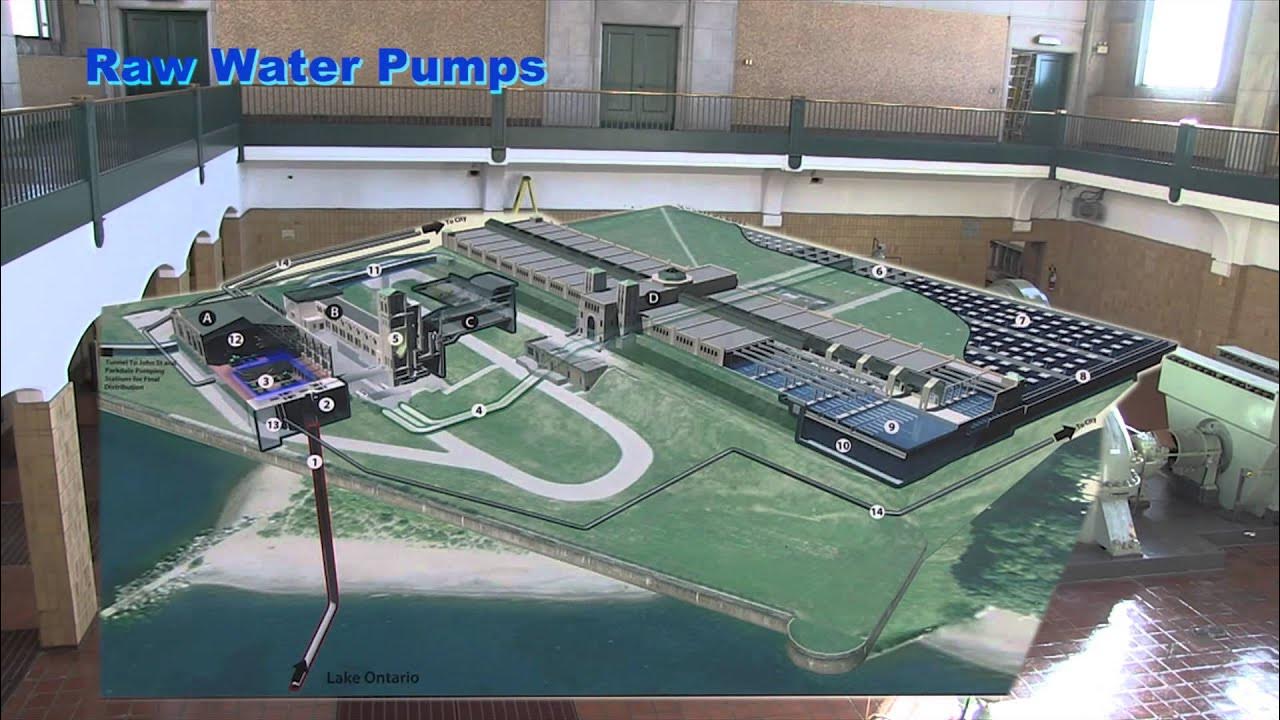

TLDRThe video script discusses the water purification process of Palija, a water service operator in West Jakarta, which manages two large water treatment plants with a combined capacity of over 6,000 liters per second. The script covers the water treatment stages, including coagulation, flocculation, sedimentation, filtration, and disinfection, ensuring the production of safe drinking water. It emphasizes the plants' compliance with international certifications (ISO 9001:2008, OHSAS 18001:2007), safety standards, and the use of advanced monitoring technology to ensure continuous, high-quality water supply to customers.

Takeaways

- 😀 Palija operates two large water treatment plants in West Jakarta, processing over 6,000 liters of water per second.

- 😀 The two plants, IPA Pejompongan 1 and IPA Pejompongan 2, are internationally certified under ISO 9001:2008 and OHSAS 18001:2007.

- 😀 IPA Pejompongan 1 has been in operation since 1957 and processes 2,800 liters of water per second, while IPA Pejompongan 2 started in 1967 with a capacity of 4,000 liters per second.

- 😀 The primary water sources for both plants are the Jatiluhur Reservoir and the Tarum Barat Canal, managed by Perum Jasa Tirta and Palija.

- 😀 Water quality at the plants is controlled to meet the Ministry of Health's standards, including processes for adjusting pH and oxygen levels.

- 😀 Chemical treatments are used in the coagulation process to remove suspended solids from raw water, followed by flocculation and sedimentation to separate impurities.

- 😀 The sedimentation process involves collecting sludge and using pre-settlers to assist in the settling of particles.

- 😀 Filtration is carried out with 48 units at IPA Pejompongan 1 and 34 units at IPA Pejompongan 2, using silica sand to filter remaining particles.

- 😀 Biofiltration further reduces pollutants like ammonium, aided by bacteria in the biofilm layer on filter media.

- 😀 Disinfection is performed with chlorine in the reservoir, ensuring bacteria are killed and maintaining residual chlorine levels to ensure water quality throughout distribution.

- 😀 The distribution of clean water is managed via a network of pumps, with performance monitored by SCADA technology to ensure quality and continuity.

Q & A

What is the primary function of Palija as an operator?

-Palija is the operator responsible for providing clean water services in the western region of Jakarta. It manages two large-scale water treatment plants capable of processing over 6,000 liters per second of raw water into clean water.

What are the two water treatment plants managed by Palija?

-The two water treatment plants managed by Palija are IPA Pejompongan 1 and IPA Pejompongan 2, which are located in Jakarta and have been operational since 1957 and 1967, respectively.

What are the capacities of the two water treatment plants?

-IPA Pejompongan 1 has a treatment capacity of 2,800 liters per second, while IPA Pejompongan 2 has a capacity of 4,000 liters per second.

Where does the raw water supply for IPA Pejompongan 1 and 2 come from?

-The raw water for IPA Pejompongan 1 and 2 comes from the Jatiluhur Reservoir, which is channeled through the Tarum Barat Canal and Banjir Kanal Barat, both under the operational control of Perum Jasa Tirta and Palija.

What are the main processes involved in water treatment at Palija?

-The main processes involved in water treatment at Palija include raw water reception, pH adjustment, oxygenation, coagulation, flocculation, sedimentation, filtration, biofiltration, and disinfection.

What is the purpose of coagulation in the water treatment process?

-Coagulation involves adding coagulants to raw water to bind suspended solids and colloids, forming microflocs that are then enlarged in the flocculation process. This helps remove impurities from the water.

What is the role of biofiltration in the water treatment process?

-Biofiltration is a process where water from sedimentation undergoes treatment by bacteria in a biofilm on the filter media, which helps reduce ammonium pollution in the water.

How is disinfection achieved in the water treatment plants?

-Disinfection is carried out by adding chlorine to the water to kill bacteria, with the chlorine dosage carefully adjusted to ensure effective disinfection. The chlorine also creates residual chlorine to continue killing bacteria during water distribution.

What technologies does Palija use to monitor and control the water treatment process?

-Palija utilizes SCADA technology for real-time monitoring of water production, transmission, and distribution, ensuring that water quality and quantity are maintained effectively.

How does Palija ensure the safety and health of its operations?

-Palija places a strong emphasis on occupational safety and health, ensuring compliance with the OSAS 18001:2007 accreditation, which reflects their commitment to workplace safety and health standards.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)