Video Pembelajaran Mengoperasikan Sistem Elektronik

Summary

TLDRThis video tutorial explains how to operate an electronic system to control the speed of a three-phase induction motor using a Variable Speed Drive (VSD). It covers the importance of adjustable motor speed in industrial applications and demonstrates the setup of a VSD with detailed wiring and configuration steps. Viewers will learn how to set parameters for motor frequency, voltage, and speed, along with hands-on demonstrations of adjusting motor speed through frequency changes. The tutorial aims to equip students with practical knowledge in motor control for industrial automation systems.

Takeaways

- 😀 The video covers the operation of an electronic system for controlling the speed of a three-phase induction motor using a Variable Speed Drive (VSD).

- 😀 VSDs help adjust motor speed by varying the input frequency and voltage to the motor, crucial for industrial automation.

- 😀 The practical goal of the activity is for students to independently operate the VSD to control the motor speed.

- 😀 The video introduces the use of a VSD to manage motor speed by adjusting the frequency input, highlighting its importance in industrial applications.

- 😀 The VSD used in this demonstration is the ATV12 HA 075 M2, which is powered by a 220V AC single-phase source and outputs a 220V AC three-phase voltage.

- 😀 The motor and VSD setup must be selected based on the specific voltage and current requirements of the system being used.

- 😀 Safety and technical equipment like a multimeter, tachometer, and tools for installation (e.g., screwdriver, tape, etc.) are important for this practical exercise.

- 😀 Key steps for wiring include connecting the single-phase voltage to the VSD, linking it to the motor, and configuring buttons and LED indicators.

- 😀 Proper parameter settings are crucial to ensure the VSD operates correctly, such as setting motor frequency, voltage, and current values in the VSD menu.

- 😀 The frequency range for the motor can be adjusted from a minimum of 10Hz to a maximum of 50Hz, influencing the motor's speed and voltage output.

- 😀 Practical tests demonstrate that increasing the frequency results in a higher motor speed, with the corresponding changes in voltage, confirming the VSD’s effectiveness in controlling motor speed.

Q & A

What is the main purpose of the video?

-The video aims to teach how to operate an electronic system for controlling the speed of a three-phase induction motor using a Variable Speed Drive (VSD), a crucial tool for automation in industrial settings.

What does VSD stand for and what is its role in motor speed control?

-VSD stands for Variable Speed Drive. It is used to control the speed of an induction motor by adjusting the frequency and voltage supplied to the motor.

Why is controlling the speed of a motor important in industrial systems?

-Controlling motor speed is important because different industrial systems require varying motor speeds—some systems need faster speeds while others require slower speeds. Some processes even demand a fluctuating motor speed.

What components are needed to operate the VSD system as described in the video?

-To operate the VSD system, the components include a three-phase induction motor, a VSD unit, a multimeter, tachometer, hand drill, cutting tools, combination pliers, wire stripper, plus and minus screwdrivers, rulers, and a single-phase MCB.

What is the significance of selecting the right VSD model for a motor?

-Choosing the correct VSD model is crucial because it must be compatible with the motor's voltage and the specific industrial application, such as the VSD model that provides 220V or 380V AC, depending on the motor's needs.

How are the components connected in the VSD system?

-The components are connected by wiring the single-phase 220V AC voltage source to the MCB, which then directs the voltage to the VSD and indicator lights. The VSD is connected to the motor through T1, T2, and T3 ports, and other necessary connections like push-buttons and LED indicators are also wired.

How do you check the connectivity of the wiring?

-To check the connectivity, an ohmmeter is used to test the connections, ensuring that everything is correctly wired before powering up the system.

What are the steps involved in setting the parameters on the VSD?

-Setting the parameters involves selecting the 'cone' or configuration menu, inputting motor specifications such as frequency (50Hz), motor power (0.25 horsepower), voltage (220V AC), current (1.2A), and motor speed (1350 RPM).

What happens when you adjust the frequency input on the VSD?

-Adjusting the frequency on the VSD changes the speed of the motor. For example, when the frequency is set to 10Hz, the motor speed is 302.5 RPM. Increasing the frequency to 30Hz and then 50Hz increases the motor speed to 878.2 RPM and 1475.2 RPM, respectively.

What is the final step after adjusting the frequency on the VSD?

-After adjusting the frequency, the motor is operated by pressing the push-button to start it. The motor’s speed and voltage are monitored using a tachometer and voltmeter to ensure correct functioning.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Cara Kerja VSD Variable Speed Drive || VFD

chocolate temp 2

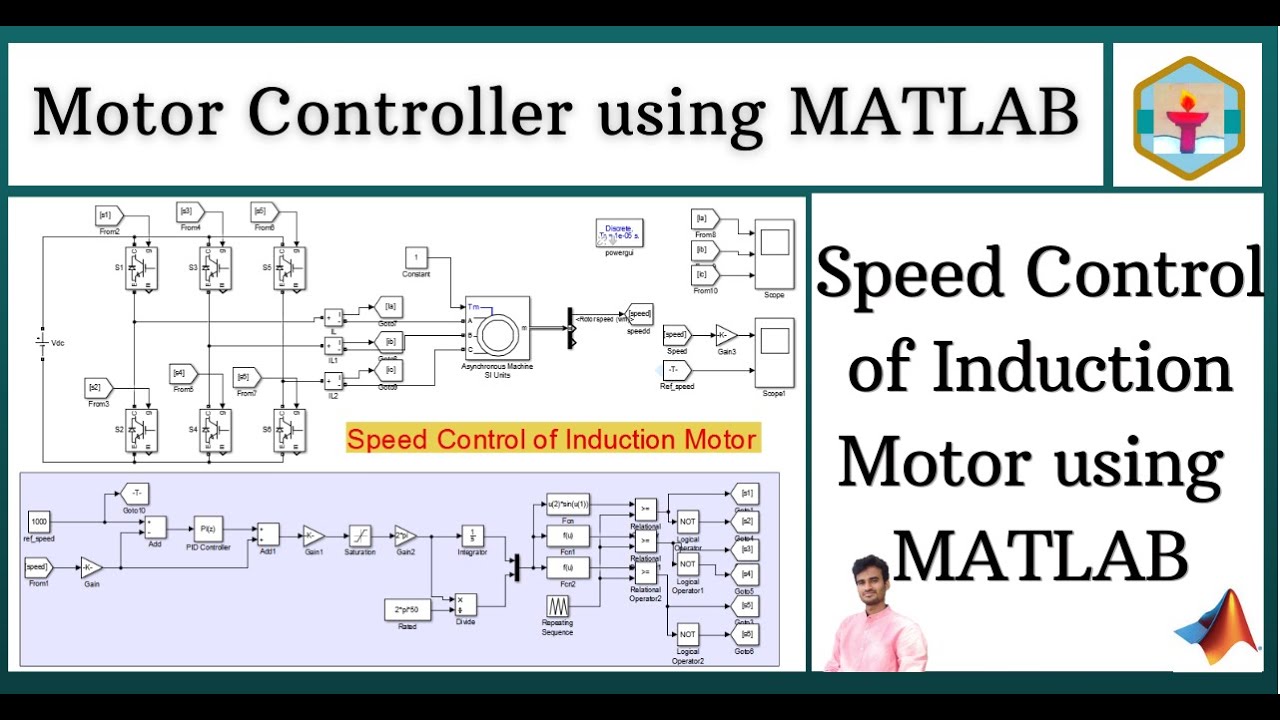

MATLAB simulation on speed control of induction motor | Scalar Control of induction motor

VFD Parameter settings - DELTA VFD - PLC Digital/Analog Output - In TAMIL - Part 03

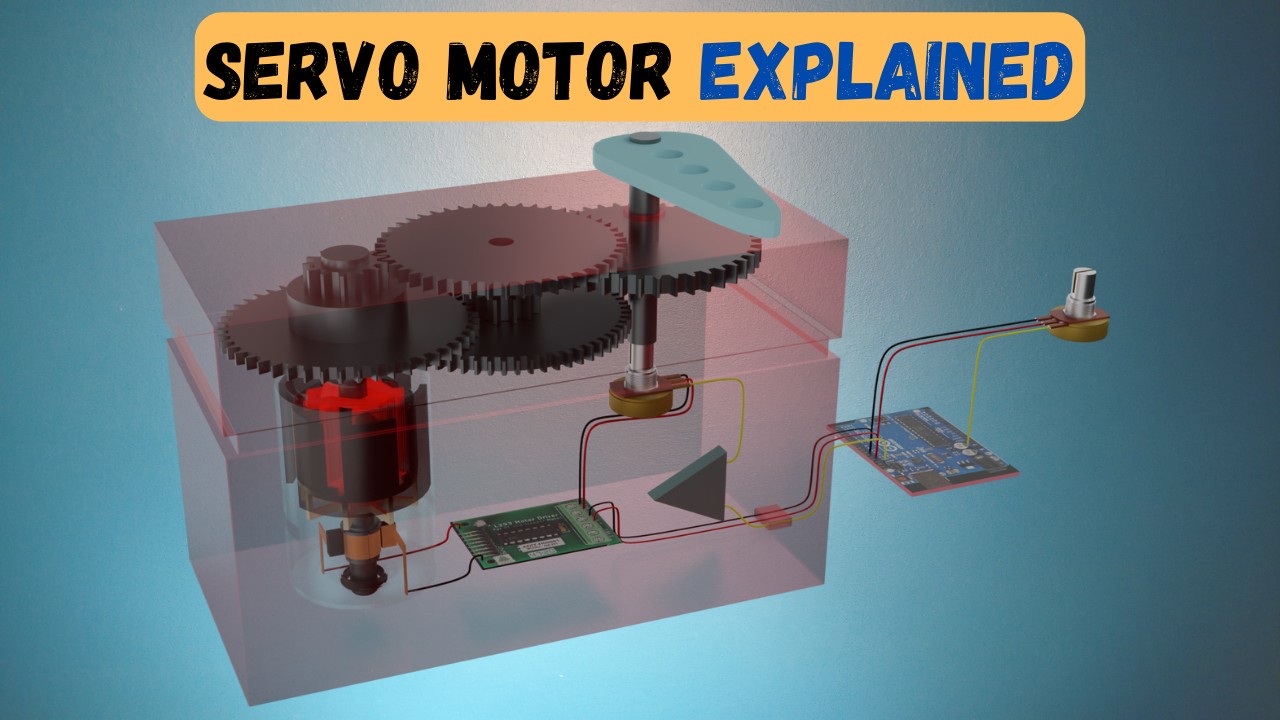

Servo Motor Explained - 3D Animation

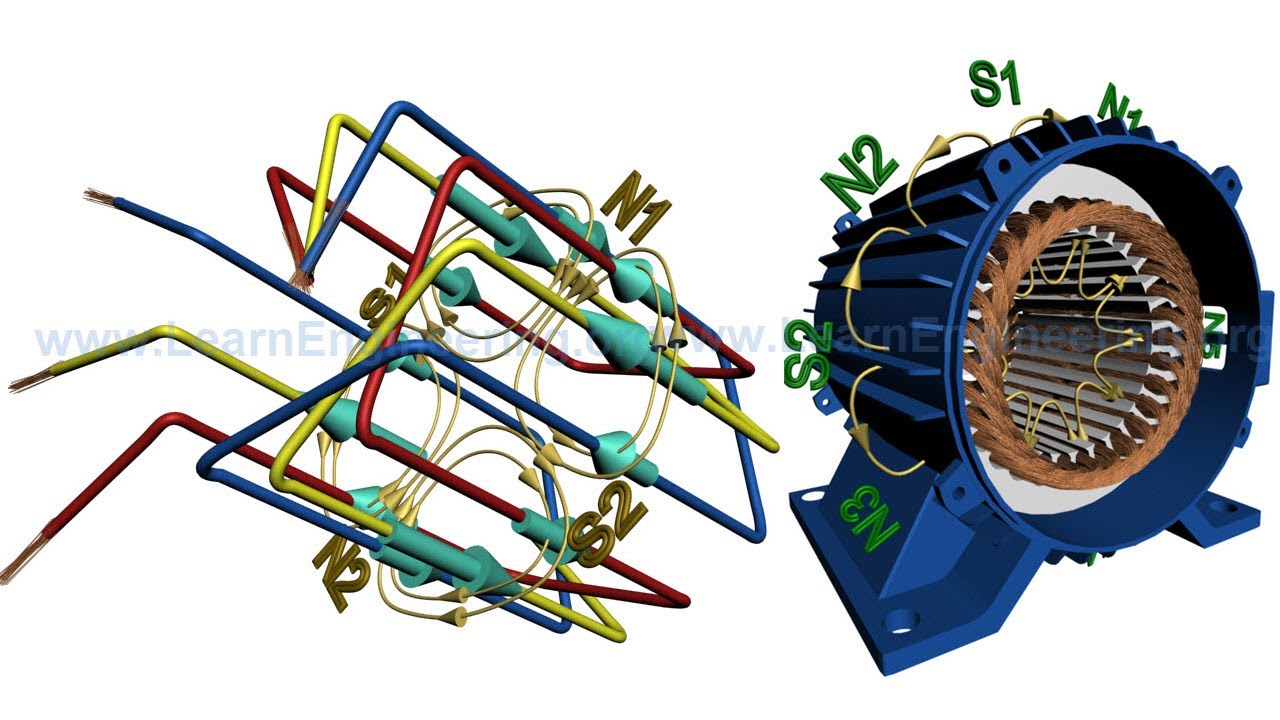

Rotating Magnetic Field & Synchronous Speed

5.0 / 5 (0 votes)