Upstream Processing

Summary

TLDRThis video explains the stages of upstream and downstream processing in biotechnology. It covers the initial steps of microbial growth, selection of microorganisms, media formulation, and optimization. The process also highlights the importance of scaling up for industrial production. The video discusses fermentation methods such as batch, continuous, and fed-batch, and how they play a role in product recovery. Additionally, it touches on genetic modification and sterilization techniques for better production efficiency. This informative guide provides viewers with a comprehensive overview of the essential processes in biotechnology and industrial fermentation.

Takeaways

- 😀 Upstream processing involves initial steps like inoculum preparation, media development, cell culture, and harvesting, which are critical for microbial growth.

- 😀 After upstream processing, the cells are harvested and transferred to the downstream section for further processing.

- 😀 Fermentation reactions are an essential part of upstream processing, where the production of desired products like alcohol or enzymes occurs.

- 😀 There are various methods for fermentation, including batch, continuous, and fed-batch methods, each suited for different product outputs.

- 😀 It is crucial to select the right microorganism based on the desired product, such as yeast for alcohol production or Lactobacillus for lactic acid.

- 😀 Genetic modification of microorganisms can enhance product yields, facilitated by modern DNA technology.

- 😀 Medium optimization is vital for ensuring the right nutrients, like carbohydrates, nitrogen, and growth factors, are provided to microorganisms.

- 😀 Scaling up the production process involves measuring the correct amounts of media and microorganisms needed to achieve large-scale production.

- 😀 A bioreactor plays a central role in the fermentation process, where inoculum and media are added, and conditions are sterilized for microbial growth.

- 😀 After fermentation, downstream processing methods are used to recover the desired product from the mixture.

- 😀 The video also provides links to other resources on fermentation and downstream processing for more detailed understanding.

Q & A

What is upstream processing in fermentation?

-Upstream processing refers to the initial steps in fermentation, which include the preparation of the inoculum (microorganisms or cells), media development, scaling up, and inoculation in bioreactors.

Why is media development important in upstream processing?

-Media development is crucial because it provides the necessary nutrients for the growth of microorganisms. Components like carbohydrates, nitrogen, fats, and oxygen must be properly balanced to optimize the fermentation process.

What are the different fermentation methods mentioned in the script?

-The fermentation methods discussed are batch, continuous, and fed-batch fermentation. The choice of method depends on the desired product and the microorganism used.

How does scaling up in upstream processing work?

-Scaling up involves adjusting the amounts of yeast, sugar, and media to meet industrial production needs. This process ensures that the desired product can be produced in large quantities.

What role do bio-reactors play in fermentation?

-Bio-reactors are used to inoculate microorganisms and provide the controlled environment necessary for fermentation. After scaling up the process, bio-reactors help in producing the desired product by maintaining optimal conditions for microorganism growth.

What is the significance of sterilization in upstream processing?

-Sterilization is critical in upstream processing to prevent contamination of the culture medium and the microorganisms, ensuring that the fermentation process proceeds without unwanted interference.

How is the right microorganism selected for fermentation?

-The microorganism is selected based on the specific product desired. For example, Saccharomyces cerevisiae is chosen for ethanol production, while Lactobacillus is used for lactic acid production. Genetic modifications may also be applied to enhance product yield.

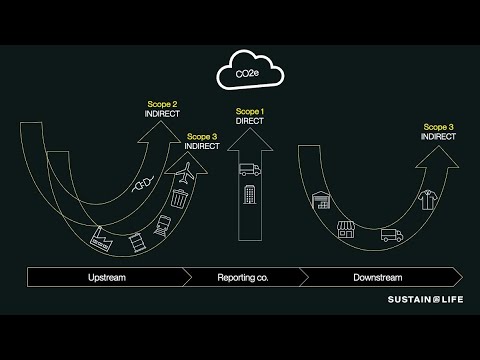

What is the connection between upstream and downstream processing?

-Upstream processing involves preparing the culture and setting up fermentation, while downstream processing focuses on recovering, purifying, and isolating the final product from the fermentation broth.

What are the components of an optimized media formulation?

-Optimized media should include carbohydrates (like glucose for energy), nitrogen sources, growth factors (such as vitamins), and oxygen to support fast metabolism and efficient product formation.

What is the purpose of screening and selecting microorganisms in upstream processing?

-Screening and selecting microorganisms ensures that the chosen strain has the desired properties for high product yield. This may also involve genetic modifications to improve performance in fermentation.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführen5.0 / 5 (0 votes)