SOLIDIFICATION OF PURE METAL | COOLING CURVE | GIBB'S PHASE RULE | NUCLEI AND GROWTH OF NUCLEI |GATE

Summary

TLDRIn this tutorial, we explore the solidification process of pure metals, focusing on the cooling curve and phase transitions. The script explains how temperature changes impact the liquid-to-solid transformation, from melting to freezing points. It highlights key concepts like nucleation, supercooling, grain formation, and the role of grain boundaries in material properties. The Gibbs Phase Rule is introduced to describe the behavior of phases during solidification. This video is an essential guide for understanding how pure metals solidify and how temperature influences their final structure.

Takeaways

- 😀 The cooling curve of pure metals shows the relationship between temperature and time during solidification.

- 😀 Point A represents the melting point, where the metal is entirely in a liquid phase.

- 😀 Point B marks the freezing point, the start of solidification, where nuclei begin to form.

- 😀 Point C indicates complete solidification when the liquid fully transitions into solid.

- 😀 The transition from liquid to solid involves the formation and growth of grains separated by grain boundaries.

- 😀 Finer grains and more grain boundaries generally result in better material properties.

- 😀 Supercooling is essential for initiating nucleation in pure metals, as they struggle to form nuclei on their own.

- 😀 The Gibbs Phase Rule is used to understand the phases and variables during solidification.

- 😀 In the liquid phase (A to B), the system follows the equation P + F = C + 1 with one phase and one variable (temperature).

- 😀 In the solidification process (B to C), the system is in two phases (liquid + solid), and temperature remains constant.

- 😀 After complete solidification (C to D), the metal remains a solid phase, and the temperature continues to decrease.

Q & A

What is the main topic of this video?

-The main topic of this video is the solidification process of pure metals, including the cooling curve and the phases involved during solidification.

What does the x-axis and y-axis represent in the cooling curve graph?

-In the cooling curve graph, the x-axis represents time, while the y-axis represents temperature.

What happens between point A and point B in the solidification process?

-Between point A (the melting point) and point B, the metal is in a completely liquid phase, and solidification begins as nucleation starts to form.

How does the freezing point relate to the solidification of pure metals?

-The freezing point is the temperature at which the liquid metal starts to solidify, marking the transition from the liquid phase to the solid phase.

What is the significance of grain boundaries in the solidified metal?

-Grain boundaries separate different grains in the solidified metal. The material’s overall characteristics depend on the grain size and grain boundary density, with finer grains leading to better properties.

Why is supercooling necessary during the solidification of pure metals?

-Supercooling is necessary to overcome the difficulties in forming nuclei at the freezing point, helping to initiate solidification and allow the formation of the solid phase.

What does the Gibbs phase rule describe in the context of metal solidification?

-The Gibbs phase rule describes the relationship between the number of phases, components, and degrees of freedom in a system. It helps in understanding the number of variables that can change during the solidification process.

How does the Gibbs phase rule apply to the liquid phase during solidification?

-During the liquid phase (from point A to point B), the Gibbs phase rule states that there is only one phase (liquid), and the degree of freedom (f) is 1, meaning that temperature can change while maintaining the liquid phase.

What happens during the B to C phase transition in the cooling curve?

-During the B to C phase transition, the metal undergoes solidification, where both liquid and solid phases are present, and the temperature remains constant until the entire liquid has solidified.

What is the solidification process like from point C to point D?

-From point C to point D, the metal is completely solid, with no liquid phase remaining. Temperature decreases, but there is no change in phase, and the metal becomes fully solid at a constant temperature.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Explanation of Solidification of Metals & Alloys | Manufacturing Processes

Materiais e Processos de Fabricação para Engenharia de Produção - Fundição - Solidificação, defeitos

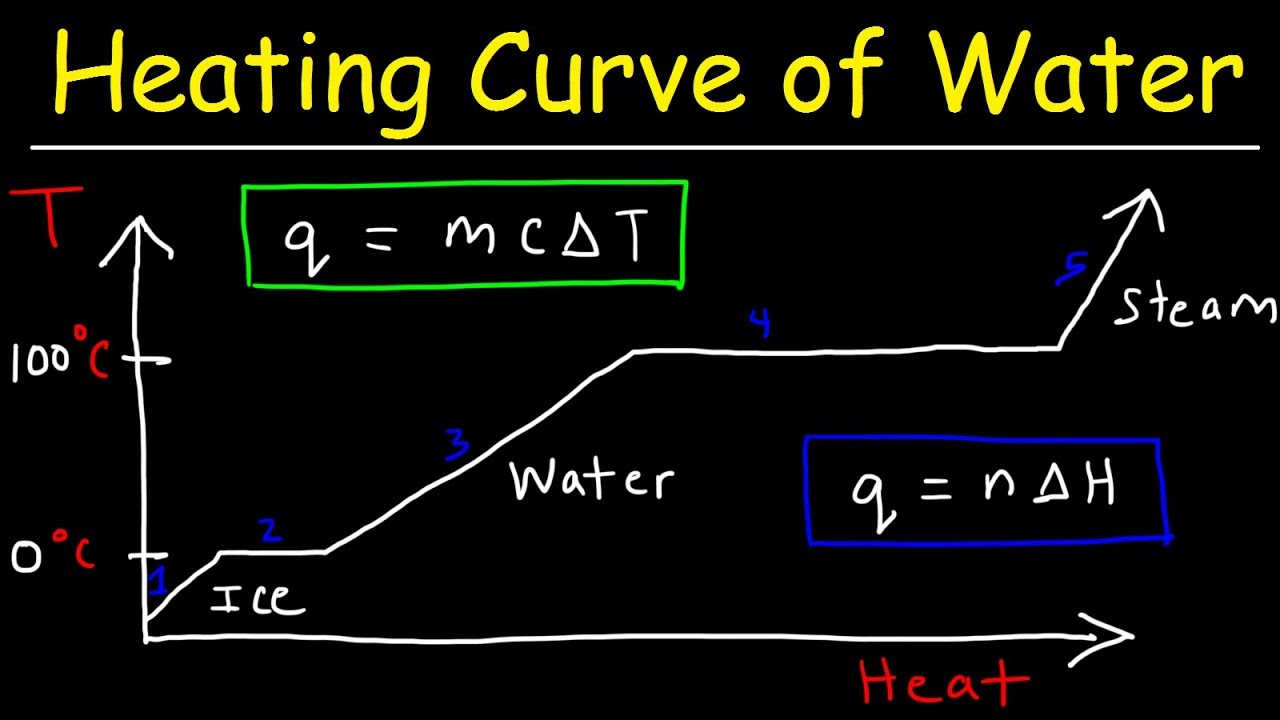

Heating Curve and Cooling Curve of Water - Enthalpy of Fusion & Vaporization

GCSE Chemistry - Extraction of Metals & Reduction #38

Física - Aula 112 - Curvas de aquecimento - Calorimetria

Dasar Pengecoran Logam Part 2 Cetakan Solidifikasi dan Penyusutan

5.0 / 5 (0 votes)