What is orifice plate & its types | Instrumentation Technician

Summary

TLDRThis video explains the concept of orifice plates, a device used to measure fluid flow rate in pipelines. It details various types of orifice plates, including concentric, eccentric, segmental, and conditioning plates, each designed for specific fluid types or flow conditions. The video also covers related devices like flow nozzles and Venturi tubes, emphasizing their advantages in reducing pressure drops or enhancing measurement accuracy. These flow measurement tools are widely used in industries such as oil and gas, chemical processing, and water treatment, offering simplicity, accuracy, and cost-effectiveness.

Takeaways

- 😀 Orifice plates are used to measure fluid flow in pipelines by creating a pressure drop across a thin plate with a hole (orifice).

- 😀 The pressure drop across the orifice is proportional to the flow rate, and the flow rate can be calculated using Bernoulli's equation or other flow equations.

- 😀 Orifice plates are widely used in industries like oil and gas, chemical processing, and water treatment due to their simplicity, accuracy, and low cost.

- 😀 One downside of orifice plates is that they create a permanent pressure drop in the system, which can reduce overall system efficiency.

- 😀 Other flow meters, like magnetic and ultrasonic meters, can be used when pressure drop is a concern.

- 😀 There are various types of orifice plates designed for different applications, including concentric, eccentric, and segmental designs.

- 😀 The concentric orifice plate is the most common type, with a centered orifice suitable for general flow measurement.

- 😀 Eccentric orifice plates are used for fluids with solids or particles, as the off-center orifice helps prevent clogging.

- 😀 Segmental orifice plates have a quarter-circumference opening, which is ideal for high flow rates.

- 😀 Conditioning orifice plates include upstream and downstream flow conditioners to reduce turbulence and enhance accuracy.

- 😀 More specialized flow measurement devices include flow nozzles, Venturi tubes, and multi-hole orifice plates, each designed for specific flow characteristics or lower pressure loss.

- 😀 Restriction orifice plates are used to reduce flow rate by creating a greater pressure drop compared to standard orifice plates.

Q & A

What is the primary function of an orifice plate?

-An orifice plate is a device used to measure the rate of fluid flow in a pipeline by creating a pressure drop across a hole in the plate, which is proportional to the flow rate.

How can the flow rate be calculated using an orifice plate?

-The flow rate can be calculated by measuring the pressure drop across the orifice plate and using Bernoulli's equation or other relevant flow equations.

What industries commonly use orifice plates?

-Orifice plates are commonly used in industries such as oil and gas, chemical processing, and water treatment due to their simplicity, cost-effectiveness, and accuracy.

What is the main drawback of using an orifice plate?

-The main drawback of using an orifice plate is that it creates a permanent pressure drop in the system, which can affect overall efficiency.

What types of flow meters might be used instead of orifice plates?

-Magnetic and ultrasonic flow meters may be used in situations where the pressure drop caused by orifice plates is a concern.

What is the most common type of orifice plate?

-The most common type of orifice plate is the concentric orifice plate, where the orifice is placed concentrically in the pipe.

What is the purpose of an eccentric orifice plate?

-An eccentric orifice plate has the orifice located off-center in the pipe and is used to measure fluids containing solids or particles that may clog the orifice.

What distinguishes a segmental orifice plate?

-A segmental orifice plate has a segmental opening, usually a quarter of the circumference of the pipe, making it suitable for high flow rates.

What is a conditioning orifice plate used for?

-A conditioning orifice plate has additional components like upstream and downstream flow conditioners that reduce turbulence and increase measurement accuracy.

What is the advantage of using a Venturi tube over a traditional orifice plate?

-A Venturi tube provides a lower permanent pressure loss than other orifice plates, making it more suitable for measuring higher flow rates with less impact on the system's efficiency.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

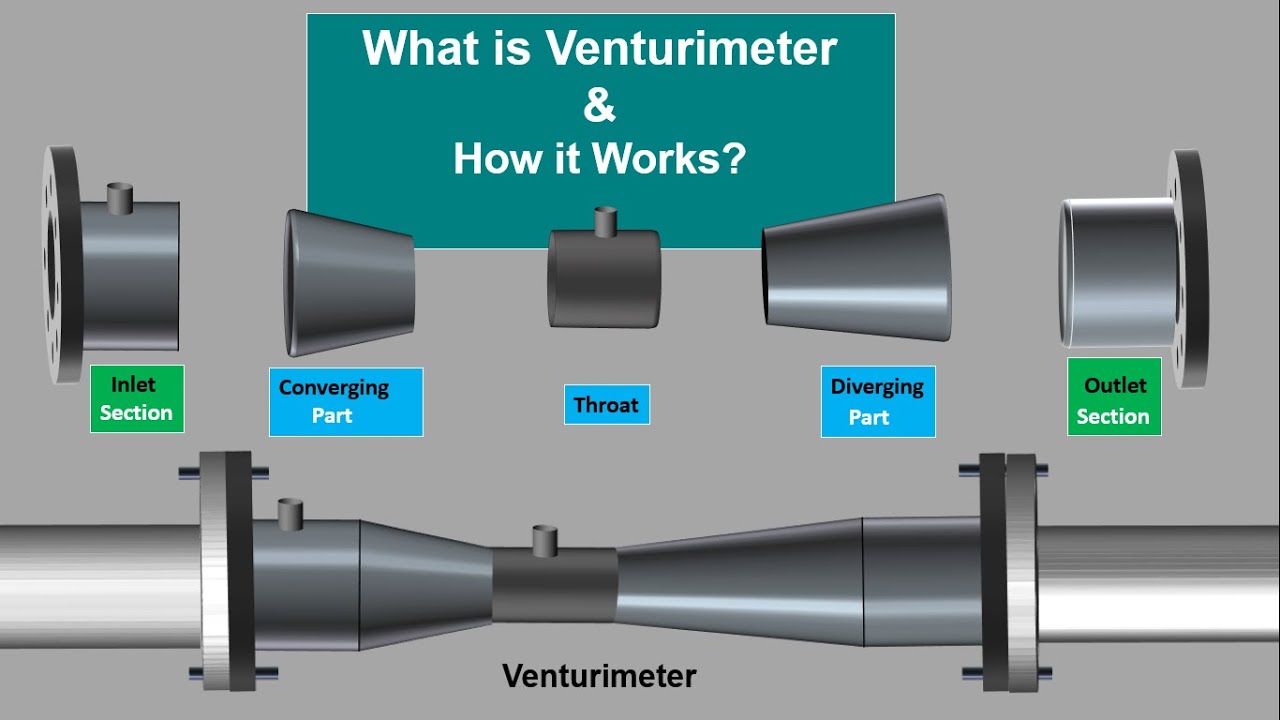

What is Venturimeter. How Venturimeter works. Working Principle of Venturimeter.Animation Video.

Rotameter Working Explanation with 3d Animation

01 - Fluid Transport - Pitot Tube

Fluida Dinamis - Konsep Bernoulli - Simple Konsep - Fisika Kelas 11

How Do Control Valve Actuators Work?

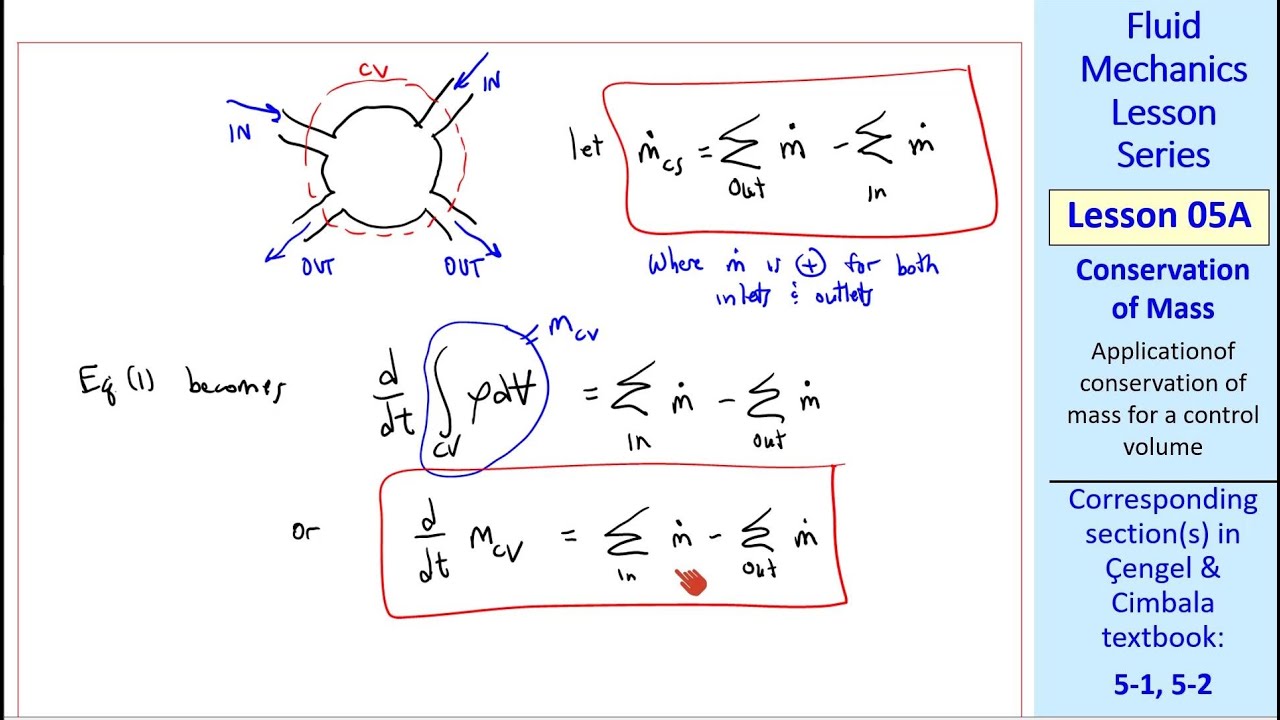

Fluid Mechanics Lesson 05A: Conservation of Mass

5.0 / 5 (0 votes)