SIG Sulap 16 Ribu Ton Sampah Jadi Bahan Bakar

Summary

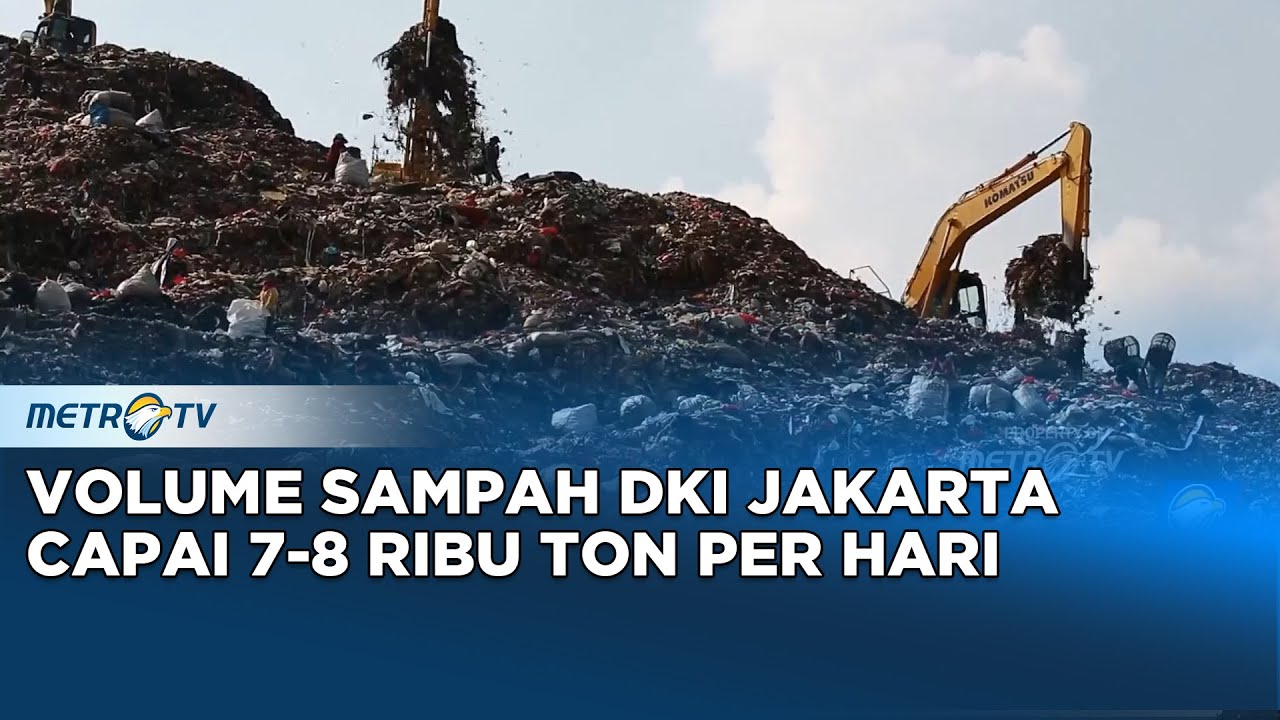

TLDRThe video highlights PT Semen Indonesia Persero Tbk's commitment to circular economy principles by converting waste into alternative fuel, specifically Refuse-Derived Fuel (RDF). With a goal to utilize this technology across all plants by 2030, the company aims to address urban waste challenges while reducing carbon emissions. Notably, their facilities in Narogong and Cilacap have processed significant amounts of waste, contributing to sustainable cement production. The initiative not only provides an eco-friendly fuel source but also represents a critical step towards environmental preservation and efficient waste management.

Takeaways

- 🌱 PT Semen Indonesia is implementing circular economy principles by converting waste into alternative fuel.

- ♻️ The company's initiative aims to address the increasing volume of urban waste amid inadequate waste management facilities.

- 🚀 By 2030, all PT Semen Indonesia plants are targeted to utilize waste-derived fuel (RDF) as a primary operational resource.

- 🏭 The technology for converting waste to RDF has been operational at two subsidiary plants since 2020, processing a total of 76,000 tons of waste.

- 📈 PT Solusi Bangun Indonesia, a subsidiary, is a pioneer in RDF production and is set to expand its waste processing capabilities significantly.

- 💡 RDF is produced from various waste sources, including municipal waste and agricultural by-products, highlighting diverse material usage.

- 🏗️ The Green Zone facility in Narogong processes around 300 tons of waste daily, providing substantial alternative fuel for cement production.

- 🌍 Utilizing RDF can significantly reduce carbon dioxide emissions in the industrial sector, aiming for a 27% decrease by 2030 compared to 2010 levels.

- ⚙️ Although RDF has lower caloric value than coal, it is seen as a viable alternative fuel to decrease reliance on fossil fuels.

- 📅 The facility's capacity and operational strategies demonstrate a long-term commitment to environmental sustainability and resource management.

Q & A

What is the main focus of PT Semen Indonesia's sustainability efforts?

-PT Semen Indonesia focuses on implementing circular economy principles by converting waste into alternative fuel, specifically Refuse-Derived Fuel (RDF).

How much waste has PT Semen Indonesia managed to convert into RDF from 2020 to 2022?

-From 2020 to 2022, PT Semen Indonesia converted a total of 76,000 tons of waste into RDF at its Narogong and Cilacap plants.

What technology does PT Semen Indonesia plan to utilize by 2030 for waste conversion?

-By 2030, PT Semen Indonesia plans to utilize waste conversion technology to implement RDF production across all its plants.

What is the estimated capacity for waste processing at the Green Zone facility in Narogong?

-The Green Zone facility in Narogong can process up to 300 tons of waste per day.

What are the environmental benefits of using RDF as an alternative fuel?

-Using RDF as an alternative fuel can reduce carbon dioxide emissions in the industrial sector and help in waste management.

How does the calorific value of RDF compare to coal?

-RDF has a lower calorific value compared to coal, but it is still a viable alternative fuel option.

What is the goal for emissions reduction associated with RDF usage by 2030?

-The use of RDF is projected to reduce CO2 emissions by approximately 27% from a 2010 baseline by 2030.

Which waste collection sites contribute to the RDF production?

-The RDF production sources include waste from TPS Bantar Gebang, Jeruk Legi Cilacap, and TPS Wangon Banyumas.

What role does PT Solusi Bangun Indonesia Tbk play in the RDF initiative?

-PT Solusi Bangun Indonesia Tbk, a subsidiary of PT Semen Indonesia, has been an initiator and operator of the first RDF facility in Indonesia.

When was the RDF facility in Cilacap officially opened?

-The RDF facility in Cilacap was officially opened on July 21, 2020, by the Coordinating Minister for Maritime Affairs and Investment, Luhut Binsar Pandjaitan.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Pengolahan Sampah Tandingan Banyumas Ada di JAKARTA! - Jangjo Indonesia

Pengolahan Sampah Dengan Teknologi RDF

Pengelolaan Sampah Padat Perkotaan

TPST Bantargebang Manfaatkan Teknologi Refuse Derived Fuel (RDF)

REALITAS - Bantar Gebang, Jantung Sampah Jakarta Bermuara

Sulap Minyak Jelantah Jadi Bahan Bakar Hijau

5.0 / 5 (0 votes)